The tire rubber powder production line is a complete solution that processes waste tires into high-purity rubber granules or powder through cutting, crushing, sorting, and grinding. The entire line features a mature structure and clear process flow. The treated rubber can be processed into rubber powder or granules of different mesh sizes, widely used in recycled rubber, rubber products, sports fields, modified asphalt, and other fields.

Compared to single-process tire pyrolysis, the rubber powder recycling line prioritizes material circularity. It can be flexibly configured as semi-automatic, fully automatic, or OTR large-tire recycling lines based on budget, tire size, capacity requirements, and automation level. This provides mature, sustainable tire-recycling solutions for clients at various development stages. Our tire rubber powder production lines offer the following advantages:

- High resource recovery rate: simultaneously separates rubber, steel cords, and fibers, achieving rubber purity exceeding 99%.

- Flexible finished product specifications: produces rubber powder ranging from 5–40 mesh; with a fine grinding system, it can reach 40–100 mesh.

- Strong configuration flexibility: from semi-automatic to fully automatic, multiple solutions meet diverse investment and production capacity needs.

- Wide applicability: processes both standard passenger tires and OTR (Off-The-Road) industrial tires.

- Stable and proven operation: clear process flow and reliable equipment design ensure suitability for long-term continuous production.

- Environmental and economic benefits: effectively reduces waste tire accumulation while enabling high-value resource utilization.

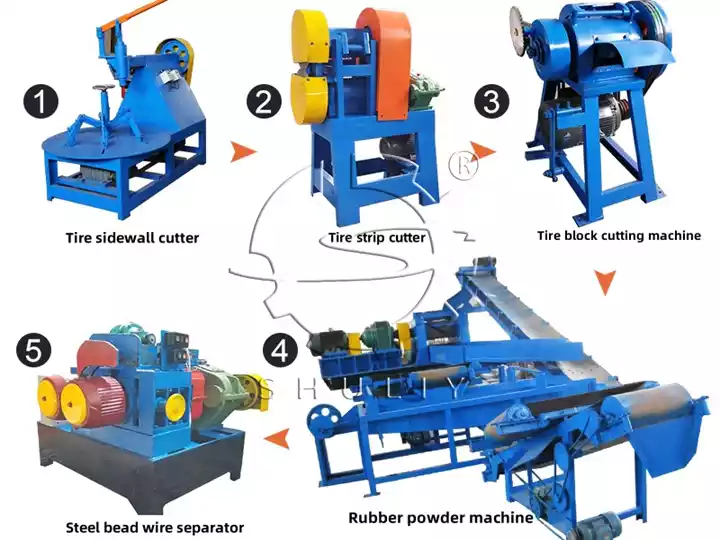

semi-automatic rubber powder production line

The semi-automatic tire rubber powder production line is designed for waste tires with a diameter of ≤1200 mm. By combining manual pretreatment with automated crushing and grinding, this solution offers a stable, cost-effective way to produce high-quality rubber powder. It is especially suitable for small and medium tire recycling plants or projects at the early investment stage.

Typical Configuration

Tire Sidewall Cutter → Tire Strip Cutter → Tire Block Cutting Machine →

Steel Bead Wire Separator → Rubber Powder Machine → (Optional) Fiber Separator

Key Features

- Lower initial investment with practical equipment configuration.

- Clear and simple processing flow, easy operation and maintenance.

- Adjustable rubber powder size, purity can reach over 99%.

- Easy to upgrade to a higher level of automation in the future.

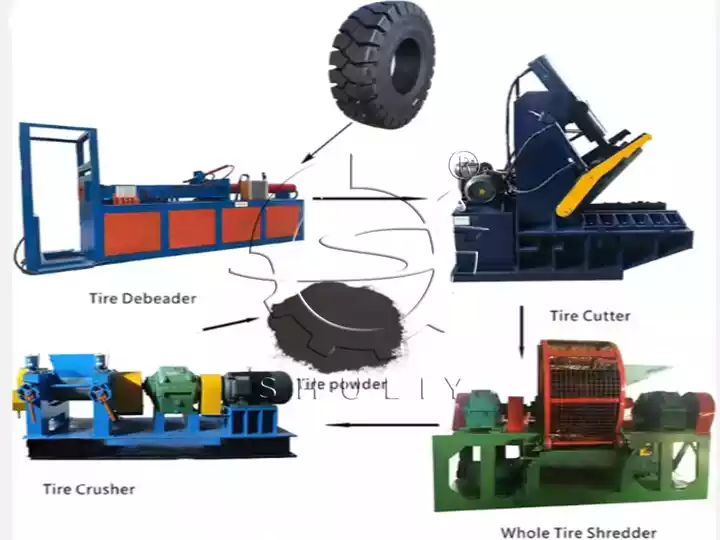

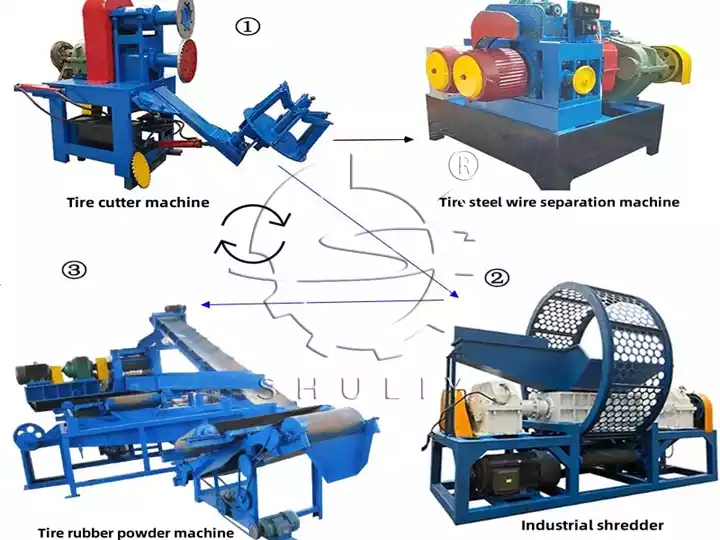

fully automatic rubber powder production line

The fully automatic rubber powder production line is also suitable for tires with a diameter of ≤1200 mm, featuring a continuous and fully automated process from pretreatment to rubber powder collection. This system significantly reduces labor requirements and is ideal for customers with higher capacity and production stability demands.

Solution 1 (Wire Drawing + Cutting)

Tire Bead Wire Drawing Machine → Tire Cutting Machine → Tire Shredder →

Intermediate Conveyor → Automatic Tire Block Storage System →

Feeding Conveyor → Rubber Powder Machine → Fiber Separator →

Rubber Powder Collection System

Solution 2 (Sidewall Cutting & Cutting Integrated)

Integrated Sidewall & Cutting Machine → Steel Wire Separator → Tire Shredder →

Intermediate Conveyor → Automatic Tire Block Storage System →

Feeding Conveyor → Rubber Powder Machine → Fiber Separator →

Rubber Powder Collection System

Advantages of Fully Automatic Solutions

- Fully automated operation with minimal labor input.

- Stable output and consistent rubber powder particle size.

- Suitable for continuous, large-scale production.

- Customizable layout according to factory space and capacity requirements.

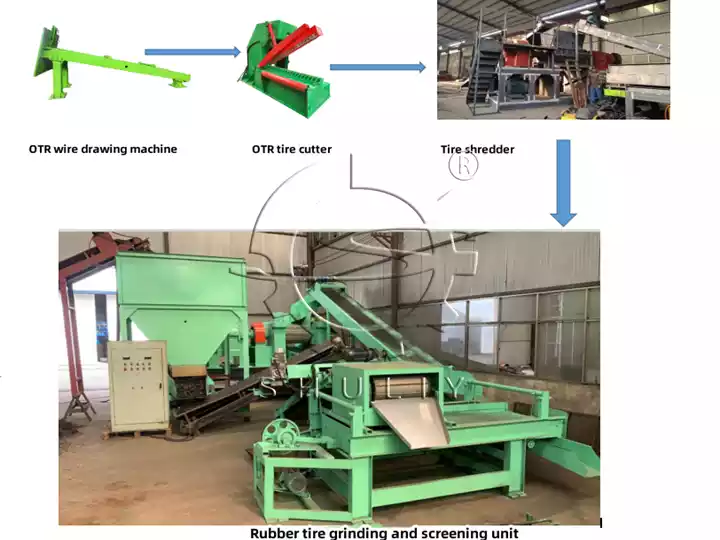

OTR large tire recycling production line

The OTR rubber powder production line is specially designed for large-size off-the-road (OTR) tires with diameters ranging from 1400 mm to 4000 mm or above, such as mining and construction tires. Due to the large size and high steel content of OTR tires, this line adopts heavy-duty pretreatment equipment and high-power grinding systems to ensure efficient and stable recycling.

Solution 1 (Wire Drawing + Cutting)

Applicable Tire Size: 1400–4000 mm

OTR Tire Wire Drawing Machine → OTR Tire Cutter → Tire Shredder (Model 1200 or above) →

Intermediate Conveyor → Automatic Tire Block Storage System →

Feeding Conveyor → Rubber Powder Machine (XKP450 or above) →

Fiber Separator → Rubber Powder Collection System

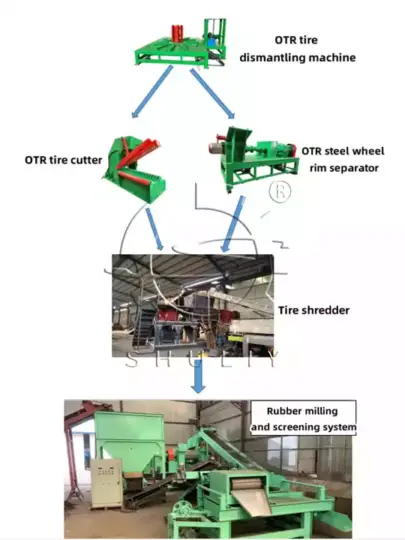

Solution 2 (Dismantling + Steel Wire Separation)

Applicable Tire Size: ≥2100 mm

OTR Tire Dismantling Machine → OTR Tire Cutter → OTR Steel Wire Separator →

Tire Shredder (Model 1200 or above) → Intermediate Conveyor →

Automatic Tire Block Storage System → Feeding Conveyor →

Rubber Powder Machine (XKP450 or above) → Fiber Separator →

Rubber Powder Collection System

Characteristics of OTR Recycling Line

- Specifically designed for oversized, high-steel-content OTR tires.

- Heavy-duty structure with stable long-term operation.

- Supports multiple rubber powder and granule size options.

- Customized solutions available based on tire structure and project requirements.

why choose us?

From semi-automatic to fully automatic systems, and extending to OTR large-tire recycling production lines, our flexible configurations adapt to your specific tire dimensions, production capacity goals, and investment plans.

Our complete tire rubber powder recycling solutions feature mature processes and strong scalability. They are equally suitable for initial entry into the tire recycling industry and for meeting long-term demands of large-scale, industrialized development.

For specific solution selection or customized configurations, we provide one-on-one recommendations based on your raw material conditions and production objectives.

FAQ

How to choose a suitable tire recycling line?

Please tell us the final product you want to produce (rubber blocks or rubber powder), as well as the required hourly capacity and output size. We will recommend the most suitable recycling line accordingly.

What size of rubber powder can be produced?

The standard output size is 5–40 mesh rubber powder.

Can the line produce very fine rubber powder?

Yes. With a fine grinding system, the production line can produce 40–100 mesh fine rubber powder.

Can this recycling line process OTR tires?

Yes. We provide specialized machines and complete solutions for OTR tires.

Do you provide installation and commissioning service?

Yes. Our engineers can go to the customer’s site for installation guidance, commissioning, and operator training.

How about spare parts supply?

One set of spare parts will be provided free of charge. Additional spare parts are available at cost price for long-term support.

Will the machines be tested before delivery?

Yes. Every machine and production line will be tested before delivery, and working videos will be provided. On-site inspection is also welcome.

What is the delivery time and packing method?

The delivery time is about 20 days after the deposit is received. Machines are packed in full containers for safe transportation.