The automatic waste metal crushing and sorting line processes various scrap metals and mixed materials, achieving high recovery rates and clean output. This integrated system combines advanced shredding technology, precision sorting systems, and eco-friendly dust removal equipment, making it an ideal choice for smelters, recycling enterprises, and metal processing plants.

This production line primarily includes key equipment such as dual-shaft shredders, metal crushers, dust collection systems, magnetic separators, and eddy current separators. Each piece of equipment works in coordination to achieve fully automated processing throughout the entire workflow—from crushing large scrap pieces to the precise separation of metals and non-metals.

wide Scope of Application and Fields of Use

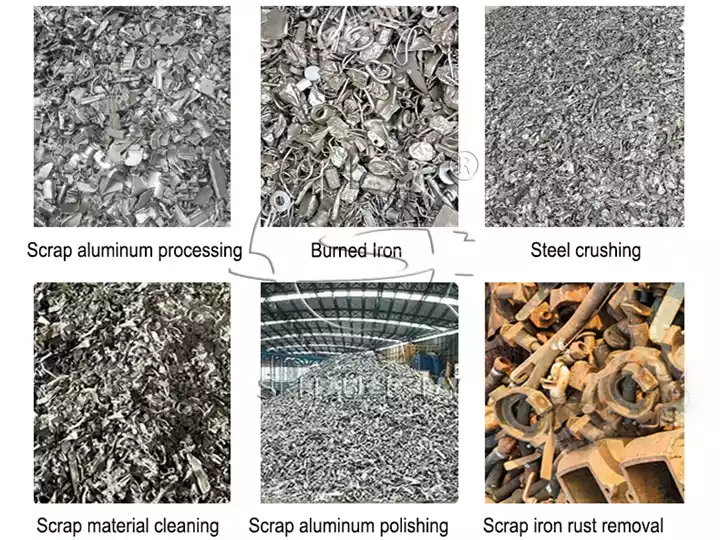

Our metal crushing and sorting line is suitable for the recovery and processing of various metals and certain non-metallic materials: motor stators and rotors, copper and aluminum coils, small transformers, circuit boards and electronic waste, aluminum parts and alloys, ferrous scrap, mixed non-ferrous metals, glass, and specific non-metallic materials.

It can also be applied in scenarios such as electronic waste, automotive dismantling, and industrial waste processing, enabling efficient resource utilization.

Importance of Crushing and Sorting in Aluminum Recycling

Aluminum possesses high recyclability and can be recycled without compromising quality. Its core significance lies in:

- Reduced volume: facilitates transportation, storage, and smelting.

- Enhanced smelting efficiency: uniformly sized aluminum scrap melts faster with lower energy consumption.

- Impurity removal: the crushing process releases adhering plastics, rubber, and other non-metallic contaminants, enhancing the purity of recycled aluminum.

- Alloy separation: sorting enables the separation of different aluminum alloys, ensuring recycled aluminum meets specific quality standards.

In scrap aluminum recycling, the proper configuration of crushing and sorting directly impacts final product quality and economic efficiency.

metal crushing and sorting line key advantages

- High-efficiency recycling: utilizes advanced dual-shaft shredding and hammer crushing technology to efficiently process materials from large waste chunks to fine fragments.

- Precise sorting: combines magnetic separators with eddy current separators to accurately separate ferrous metals, non-ferrous metals, and certain non-metallic materials.

- Eco-friendly design: equipped with a high-efficiency dust collection system to prevent secondary pollution during crushing and sorting.

- Energy-efficient and reliable: fully automated with a rational structure, low power consumption, minimal maintenance costs, and stable operation.

- Customized solutions: tailored production lines with varying capacities and configurations to meet the specific needs of different recycling enterprises.

To help you better understand the functions of each piece of equipment, we will now provide a detailed introduction to the key individual machines in the metal crushing and sorting line.

double shaft shredder

The industrial twin-shaft shredder is a highly efficient material reduction device that pulverizes large waste pieces into controllable, smaller fragments through shearing, tearing, and compression. Characterized by uniform output and controllable particle size, it serves as the critical primary shredding equipment in metal crushing and sorting lines.

Applicable Material Range

Capable of processing various bulky or high-toughness materials, including beverage cans, paint cans, iron filings, automobile bodies, discarded appliance casings (plastic/metal), large pipes and fittings, forklift pallets, tires, aluminum, copper, iron sheets under 5mm thick, scrap circuit boards, and waste cables.

Working Principle

- The shredder employs a dual-shaft independent drive design, generating self-pressurization during operation to enable automatic feeding.

- Materials enter the shredding chamber via the feed system, where multiple sets of high-strength shredding blades are installed. Through combined shearing, tearing, and compression forces, materials are shredded into small pieces and discharged from the chamber’s lower section.

- The unique shaft-blade structure combined with four-corner rotating blades prevents shaft entanglement or equipment jamming even under low-speed, high-torque conditions, ensuring long-term stable operation.

Waste Processing and Multi-Functional Applications

Beyond metal recycling, the twin-shaft shredder processes highly resilient and viscous materials like plastics, rubber, and industrial waste, delivering multi-purpose functionality.

It plays a vital role in waste volume reduction (shredding solid waste, household garbage, food waste, electronic waste, yard waste, and animal byproducts), resource recycling, and environmental treatment, providing a robust foundation for metal crushing and sorting lines.

technical parameters

| Model | Tool Specification | Power(kW) | Number of Tools | Capacity(kg/h) | Inlet Size(mm) |

| 600 | 216×20 | 15×2 | 27 | 700–1000 | 600×460 |

| 316×30 | 22×2 | 21 | 700–1000 | 600×570 | |

| 1000 | 316×30 | 30×2 | 27 | 2000–4000 | 1000×570 |

| 400×40 | 45×2 | 17 | 2000–4000 | 1000×720 | |

| 450×50 | 55×2 | 17 | 2000–4000 | 1000×850 | |

| 1200 | 450×40 | 45×2 | 27 | 3000–5000 | 1200×850 |

| 500×50 | 75×2 | 23 | 3000–5000 | 1200×980 | |

| 2000 | 550×60 | 75×2 | 27 | 5000–9000 | 2000×1150 |

| 650×60 | 90×2 | 29 | 5000–9000 | 2000×1250 |

metal crusher

The scrap aluminum crushers tear and crush metal into manageable sizes of 3–10 cm, making them ideal front-end processing equipment for metal smelting plants, recycling facilities, and steel enterprises. They can also be used for centralized processing of metal chips at fixed locations.

machine detais

- Wear-resistant hammer heads and screen plates: cast from high-strength alloy steel for extended wear life and high crushing efficiency. Tool configurations can be adjusted based on material properties.

- Heavy-duty rotor structure: reinforced rotor with cast steel bearing housing design enhances overall strength and operational stability.

- All-copper core motor: delivers robust power, low energy consumption, and extended service life.

- Reinforced frame: constructed with extra-thick steel plates and high-strength welding techniques for superior impact resistance, wear resistance, and enhanced safety reliability.

- Safety protection system: features overload protection, interlocking devices, and sealed feed openings to prevent material ejection and ensure operational safety.

Working Process

- Metal materials enter the crushing chamber through the feed inlet. Under the combined impact, shear, and friction forces generated by the high-speed rotating hammers and rotor, the materials are rapidly crushed.

- The crushed materials are subjected to centrifugal force and repeated hammer impacts, reducing them to a size that can pass through the screen plate apertures (3–10 cm). The processed material is then discharged from the bottom.

- By adjusting the screen plate aperture and tool configuration, the final output size can be flexibly regulated to meet diverse metal recycling requirements.

technical data

| Model | Power(kw) | Rotation speed(r/min) | Capacity(kg/h) | Size(mm) |

| BDL-600 | 18.5-22 | 860 | 600-800 | 2000x1200x1900 |

| BDL-800 | 30-37 | 860 | 800-1000 | 2200x1500x2200 |

| BDL-1000 | 55-75 | 860 | 2500-3500 | 2800x1900x3100 |

| BDL-1300 | 90-110 | 750 | 3500-5000 | 3500x2100x3800 |

| BDL-1600 | 110×2 | 750 | 4000-8000 | 4400x2500x4200 |

| BDL-1800 | 160×2 | 650 | 8000-12000 | 4700x2900x4500 |

| BDL-2000 | 220×2 | 650 | 10000-18000 | 5000x3200x4600 |

Eddy current separator

Eddy current separators represent a new generation of equipment for separating metals from non-metals, primarily used to automatically segregate various non-magnetic non-ferrous metals such as copper, aluminum, and zinc. They deliver exceptional separation performance for non-ferrous metal materials with particle sizes exceeding 2mm.

Wide Range of Applicable Materials

This scrap steel sorting equipment is suitable for processing a diverse range of crushed materials, including municipal solid waste, industrial solid waste, electronic scrap, glass fragments, waste plastics, and mixed metals.

It is particularly effective in recovering non-ferrous metals, such as copper and aluminum. Their strong adaptability enables them to meet nearly all sorting requirements of metal recycling enterprises.

Working Principle

- The eddy current separator utilizes the differing electrical conductivity of metals. When exposed to a rapidly changing magnetic field, eddy currents are generated, producing repulsive forces that automatically separate non-ferrous metals from non-metals.

- The equipment achieves separation through physical means, generating no exhaust gases or wastewater. A high-speed magnetic roller accelerates rotation, propelling metal particles onto distinct trajectories to achieve precise separation.

Core Advantages

- Compared to traditional manual sorting methods, eddy current separators deliver significant improvements in sorting quality and speed.

- The magnetic roll features forward and reverse rotation control, allowing flexible adjustment based on material size, center of gravity, and shape. This enables the equipment to adapt to more complex sorting environments.

- High-precision separation is achievable for both fine particles and larger metal fragments.

machine parameters

| Model | Rotary speed (r/min) | Belt width (mm) | Capacity (t/h) | Power (kw) | Weight (kg) | Dimensions (mm) |

| 600 | 0-3000 | 650 | 4-6 | 4.0+0.75 | 1400 | 2980 X 1883 X 1210 |

| 800 | 0-3000 | 850 | 6-10 | 5.5+1.1 | 1800 | 2980 X 2033 X 1210 |

| 1000 | 0-3000 | 1050 | 10-12 | 7.5+1.5 | 2200 | 2980 X 2233 X 1210 |

| 1200 | 0-3000 | 1250 | 12-15 | 11+2.2 | 2400 | 2980 X 2433 X 1210 |

metal dry mill

The metal dry grinding and polishing machine is an optional auxiliary device for metal crushing and sorting lines, primarily used for deburring, rust removal, chamfering, and surface polishing of metals, hot-worked iron, non-ferrous metals, and non-metallic components.

It is particularly suitable for finishing easily deformed workpieces, improving surface roughness by 1–2 grades without altering original dimensional accuracy. This machine is ideal for surface treatment of medium to large-sized workpieces.

Working Principle

- The equipment employs an electric motor and reducer to drive the drum rotation, handling metal or scrap aluminum materials with oil or rust contamination up to 400mm in diameter.

- Within the drum, materials and abrasive media undergo continuous tumbling, rolling, friction, and agitation. This process enables the abrasive media to adsorb and remove oil and rust from material surfaces, achieving highly efficient dry degreasing and rust removal.

cases of metal crushing and sorting line

Whether you need to increase production capacity, enhance metal purity, or reduce labor costs, we can provide you with customized system configurations and technical support. Contact us today for professional solutions and quotes on metal crushing and sorting lines.