As scrap metal recycling costs continue to rise and environmental regulations grow increasingly stringent, scrap metal briquetting machines are emerging as a vital tool for businesses to boost profitability. By compressing loose scrap into high-density metal blocks, they not only elevate the scrap’s value but also significantly reduce transportation costs and metal loss.

Enhancing Scrap Value and Recovery Rates

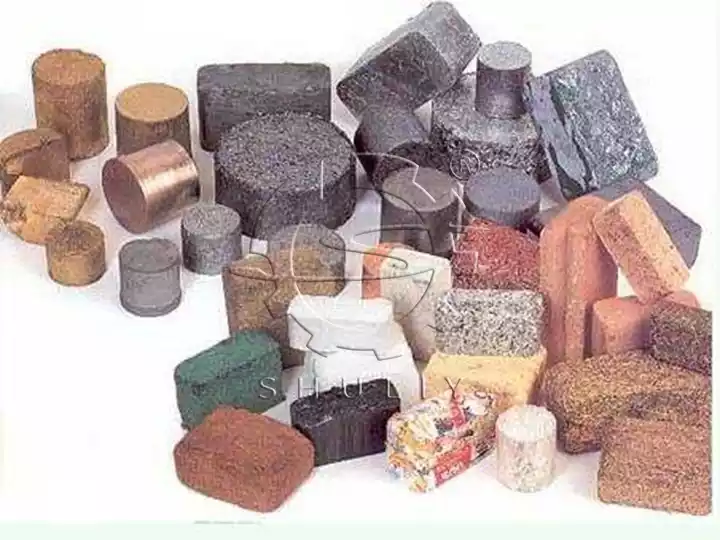

Scrap materials like steel chips, aluminum shavings, copper filings, and cast iron turnings are typically bulky, low-density, and oil-laden, making them difficult to handle and sell.

- Metal briquettes making machines compress these scraps into uniform, high-density bales, increasing density by 3–5 times.

- Briquetted metal is easier to transport and store, making it more appealing to steel mills and smelters, commanding significantly higher prices than loose scrap.

- Briquetting also reduces smelting burn loss by 10–15%, with particularly notable effects on aluminum and copper chips.

This means more actual metal can be recovered from the same volume of scrap, boosting corporate profit margins.

Reducing Costs and Improving Efficiency

- Briquetted metal occupies significantly less space, reducing storage requirements by 70%–80%. Per-vehicle loading capacity increases substantially, cutting logistics costs by 30%–50%.

- Simultaneously, the briquetting process recovers 90%–95% of cutting fluids or coolants for reuse. This reduces procurement expenses, minimizes waste liquid discharge, and aligns with modern green production standards.

- Small-to-medium metal briquetters process 1–3 tons of scrap per hour, with flexible model selection based on workshop needs.

- Equipment investment typically pays off within 6–12 months. For small-to-medium processing plants and scrap recycling stations, it represents an ideal choice for rapid profitability.

scrap metal briquetting machine Wide Applications

Metal chips briquetting machines are extensively used in machining plants, aluminum factories, steel workshops, and scrap metal recycling centers. By enhancing scrap value, reducing transportation and storage costs, and improving metal recovery efficiency, they help businesses achieve more environmentally friendly production processes.

Additionally, balers adapt to diverse metal types—including steel, copper, aluminum, and cast iron—offering broad processing capabilities and high flexibility. For modern metal recycling enterprises seeking to boost scrap utilization, minimize losses, and increase profits, scrap metal briquetting machines for recycling have become indispensable core equipment.