塑料造粒机,也称为塑料颗粒机,是废塑料回收和再利用过程中不可或缺的设备。凭借特殊的螺杆设计和多种配置,该设备适用于PP、PE、PS、ABS、PA、PVC、PC、POM、EVA、LCP、PET、PMMA等塑料材料的再生造粒和色母粒造粒。

工业废物和农业塑料残留物可以高效处理并转化为可重复使用的颗粒原材料,这些原材料广泛用于塑料产品的再制造。我们提供灵活的定制选项、低能耗操作和简化的操作流程。整套设备只需1~2人即可操作,帮助企业节省成本,提高效率。

塑料造粒机的用途

该机非常适合饮料瓶、商业袋、垃圾袋、农膜、食品包装、收缩膜和拉伸膜等包装膜生产商以及编织行业的PP编织袋和集装袋生产商。

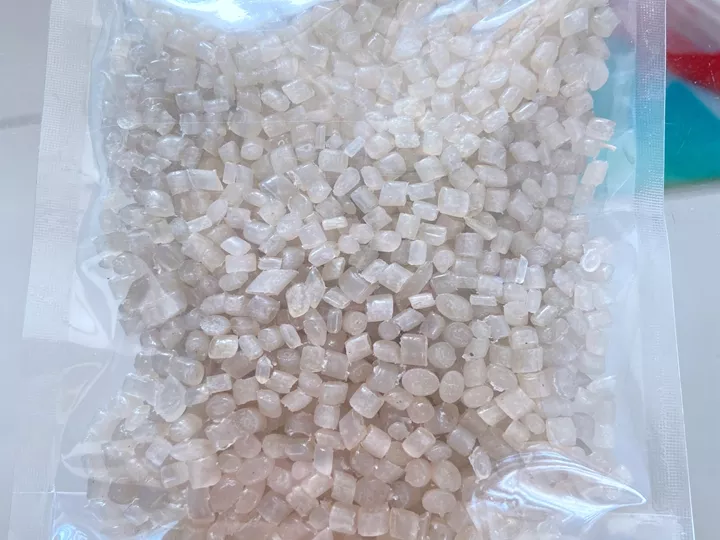

PP PE 颗粒挤出机的最终产品

- 颗粒形状和大小均匀,表面光滑,没有毛刺。

- 颗粒的密度适中,具有优良的物理特性,如高强度、耐磨性和耐腐蚀性。

- 无需冷却和干燥,清洗后的塑料可以直接造粒,简化了操作流程。

- 采用电磁加热和自动温控技术,节能并避免二次污染。

- 生产的再生颗粒可以100%用于新产品的制造,回收率高,经济效益好。

塑料造粒机的优点

- 可以处理多种通用和工程塑料,以满足各种回收需求。

- 具有间歇加热功能,整体能耗降低约20%,降低了运营成本。

- 螺杆和筒体经过特殊淬火处理,耐磨且使用寿命长。

- 采用高扭矩齿轮箱设计,运行平稳,无噪音污染。

- 高度自动化,仅需1-2人操作,减少了劳动力投入。

- 根据材料特性提供不同的螺杆结构和配置方案,以确保造粒效果。

- 日处理能力可达20~30吨,能够满足中大型塑料回收厂的批量生产需求。

塑料造粒机配套设备

塑料颗粒机需要与破碎机、洗涤机以及塑料颗粒切割机配合使用。废塑料的清洗和干燥是回收的第一步。

然后,干净的塑料通过塑料造粒机的螺杆挤出机被熔化并塑化,挤出成条。然后经过冷却,通过塑料颗粒切割机切割成颗粒。这些颗粒可以通过吹塑、注塑、压延等工艺加工成各种塑料产品。

将大塑料材料粉碎成小颗粒。这有助于后续加工和处理并提高颗粒机的效率。

污染物被去除,提高颗粒的成品质量并减少后续设备的磨损。

塑料颗粒切割机

颗粒切割机是回收行业的重要组成部分。精细切割使颗粒尺寸更加均匀一致,满足不同产品对颗粒尺寸的需求,有利于提高最终产品的质量和一致性。

塑料造粒机是如何工作的?

塑料造粒机主要有三种加热方式:电磁加热、陶瓷加热和感应加热。您可以根据具体需求选择不同的加热设备。

您也可以咨询我们;我们会为您的材料推荐合适的机器。塑料颗粒机的工作原理主要包括以下几个步骤:

- 熔化:废塑料通过加热系统在机器内部熔化,使其处于流动的熔融状态。

- 挤出:熔融塑料通过螺杆挤出系统,在高压和高温的作用下被挤出成连续的颗粒形式。

- 冷却:快速冷却和固化确保颗粒的形状和质量。

- 切割:通过机器内的切割系统将连续的颗粒材料切割成所需长度的颗粒。

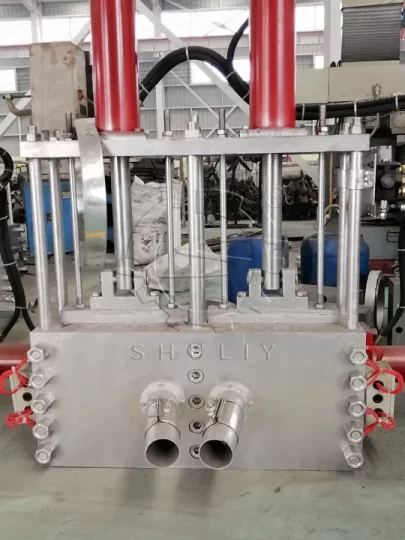

模头的三种类型

塑料造粒机的模头控制温度、压力、挤出速度等,直接影响颗粒的质量和形状。有电动齿轮模头、液压模头、自动滤渣器三种。

废旧塑料挤出机成功案例

舒利的塑料造粒机已成功出口到美国、德国、巴西、印度、日本、澳大利亚、韩国、南非、土耳其、越南等多个国家。

最近,一位来自南苏丹的客户,他在回收业务中,购买了我们的塑料回收造粒线。该客户是第一次购买回收机,安装过程非常紧张。

我们的技术团队在安装过程中通过视频会议支持客户。客户按照说明独立安装了整台机器。以下是使用现场的反馈。

pP PE造粒机技术参数

整个过程通过控制加热、压力、挤出速度、切割长度等参数,可以精确调节颗粒的形状、尺寸和质量,以满足不同的生产要求。

| 类型 | 150 | 180 | 200 |

| 螺杆直径 | 150毫米 | 180毫米 | 200毫米 |

| 主轴转速 | 40-50/分钟 | 40-50/分钟 | 40-50/分钟 |

| 主电机功率 | 37千瓦 | 55千瓦 | 75千瓦 |

| 减速机(硬齿面) | 250 | 280 | 315 |

| 重量 | 2T | 2.2T | 2.8T |

| 尺寸 | 3.0*0.7*0.8m | 3.2*0.7*0.8m | 3.5*1*1m |

| 输出 | 300公斤/小时 | 350公斤/小时 | 380公斤/小时 |

我厂有多种型号的塑料造粒机制造可供选择,欢迎随时与我们联系。我们可以为您推荐最合适的型号。