废旧塑料薄膜造粒线专门设计用于破碎、清洗、干燥、造粒,最终将废薄膜转化为再生塑料颗粒。获得的颗粒用于制造各种新型塑料产品。我们可以提供不同容量的机器,范围为 500-2000kg/h。

由于其高效的性能和卓越的品质,舒利的塑料造粒机已成功出口到美国、加拿大、肯尼亚、尼日利亚、沙特阿拉伯、埃塞俄比亚、墨西哥、阿根廷、南非、印度、澳大利亚等四十多个国家。很快。

适用原料

塑料薄膜造粒线适用于加工各种 LDPE HDPE LLDPE PP BOPP PVC PET PS 类型的薄膜废料。这些通常来自农用薄膜、编织袋、保鲜膜、保鲜膜、卫生巾包装、塑料包装袋等应用。

当然,如果您要处理的原材料是硬塑料,那么您有一个选择:HDPE PP PS 硬刚性废塑料造粒回收生产线.

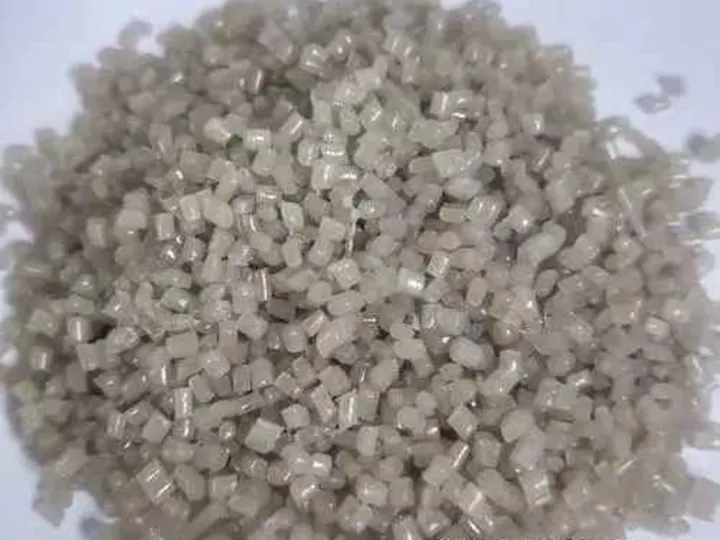

您可以获得的最终颗粒

成品颗粒质量高、尺寸均匀。颗粒尺寸和形状可以定制。回收的薄膜颗粒可用于吹膜、制管和其他塑料注射。

塑料薄膜造粒线工作流程

- 首先,通过粉碎机械将薄膜撕成小片。

- 接下来,通过清洗设备去除污染物和杂质。

- 随后,将薄片熔化并压缩以形成均匀的条带形式。

- 最后通过颗粒冷却和切割设备得到高质量的再生塑料颗粒。

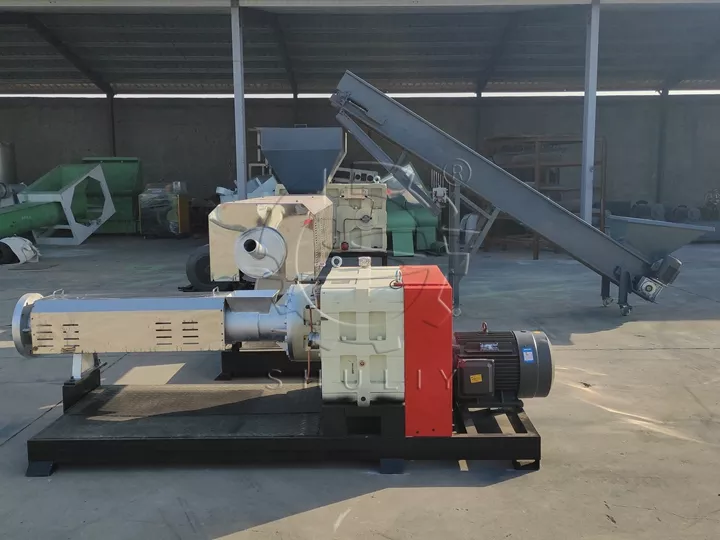

造粒回收厂主机

整个回收线的工作流程要经过一系列机器,下面介绍一些核心设备。我们有多种机型可供配置,下面列出的部分参数仅供参考。

废塑料破碎机

用于塑料薄膜造粒生产线的预处理,以减少废料量。

- 型号:1000

- 功率:37kw+11kw

- 产能:1000公斤/小时

安装了多个齿式搅拌器,将塑料碎片向前推进,以实现彻底清洁。

高速旋转,使洗涤后的塑料碎片在离心力的作用下脱水,达到一定的干燥度后进行造粒。

冷却槽

冷却刚刚通过造粒机生产的热塑性颗粒。在塑料薄膜造粒生产线中,热塑性颗粒需要快速冷却。这确保它们保持固体形式以供进一步加工和储存。

为了满足各种应用需求,通常使用定制颗粒尺寸,将长挤出塑料条切割成均匀的较小颗粒,用于特定产品或工艺。

- 型号:SL-220

- 螺杆直径:220mm

- 螺杆长度:L1.6m

- 电机:22+18.5kw

塑料颗粒储存箱

用于储存加工至此的颗粒,以及包装和运输等以供销售。

其他可选设备

根据客户的预算和生产意向等,我们还有套袋机供您按需选择。另外,为了使塑料薄膜造粒线更加环保,我们还配备了废气净化器。

舒利废旧塑料回收线优点

- 节省成本: 投资塑料薄膜造粒线机器可以帮助企业降低原材料成本。他们可以使用回收颗粒,而不是购买原生塑料,这种颗粒更便宜,但仍符合质量标准。

- 多功能应用: 这些机器生产的再生塑料颗粒具有广泛的应用。它们可用于制造新产品,包括包装材料、儿童玩具、管道等。

- 减少原生塑料的使用:再生塑料的使用减少了对原生塑料的需求,有助于缓解塑料短缺问题。

- 产品质量提升:使用再生塑料颗粒可以提高塑料制品的质量和性能,减少浑浊等缺陷。

常见问题解答

塑料薄膜回收机可以同时加工PP和PE材料吗?

塑料薄膜洗涤回收线可以处理各种材料,但它被设计为一次只能处理一种类型,以保持最终产品的纯度和质量。由于 PP 和 PE 的熔点不同,该机器无法同时处理不同种类的塑料.

造粒机的加热方式是什么?

造粒机采用电磁加热、铸铝加热圈、陶瓷加热圈或石英管加热圈,具体取决于原料加工需要和客户要求。

需要多少操作员?

这取决于您的生产线的规模。一条500公斤/小时的塑料薄膜造粒线需要2-3名工人,而一条1000公斤/小时的塑料薄膜清洗回收线需要3-5名工人。

回收工厂应该有多大?

对于一条500公斤/小时的塑料薄膜造粒线,所需空间为40m x 15m x 6m。对于 1000 kg/h 的生产线,所需空间为 50m x 15m x 6m。我们的项目经理将为您设计机器放置布局。