金属剪是金属回收加工中的关键设备,广泛用于钢铁、铝、铜等废金属的剪切和加工。根据不同的加工需求,目前常用的金属剪主要包括鳄鱼剪、老虎剪和三种大型龙门剪。

这三种类型的机器配备了高效且精确的剪切能力,通过液压系统驱动合金刀具组(硬度HRC58 ± 2),可以瞬间切断厚度达到40cm的废金属。

三种金属剪板机的区别

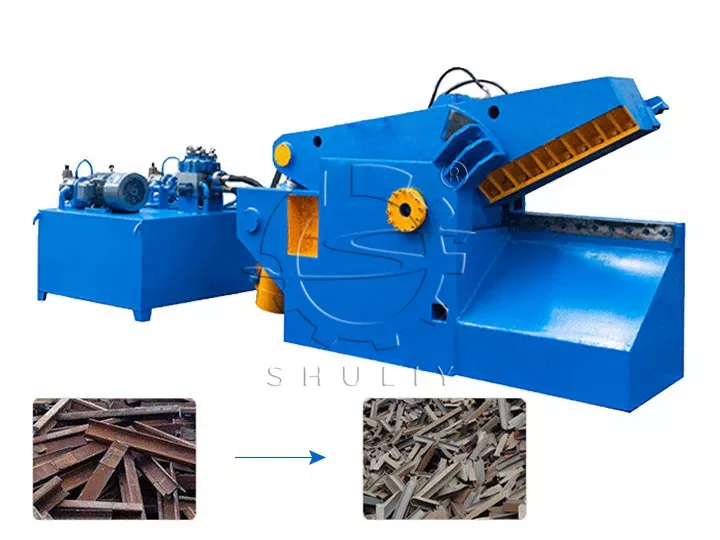

鳄鱼剪切机:以其强大的切割力和紧凑的设计而闻名,可处理中小型金属材料。它通常具有一个旋转的剪刀,能够剪切钢筋、管道和金属板等材料。

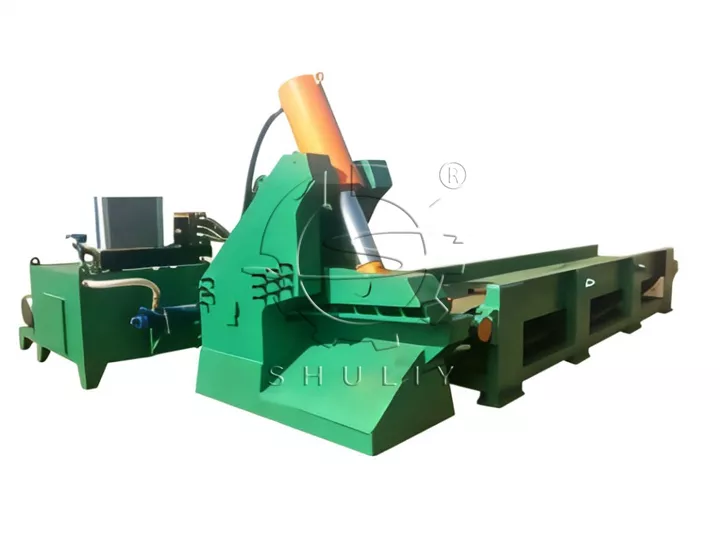

虎头剪切机:它被设计成更适合处理大型和重型金属材料,如钢梁和废旧机械。它之所以得名,是因为它的剪刀形状像虎头。虎头剪切机通常采用双剪刀,以提供更大的剪切力和稳定性。

龙门剪切机:这是一种重型金属剪切机,设计用于处理超大尺寸和厚度的金属材料,如报废船舶和大型金属部件。它利用大型机械臂和多个剪刀片来实现强大的剪切能力。

金属切削机床的工作原理

金属剪刀通过将金属材料放置在剪刀之间施加剪切力来切割金属。

鳄鱼剪和老虎剪通常由液压系统驱动,而龙门剪主要由高功率电动机和机械传动系统驱动。

不同型号的剪刀配备了不同设计的刀具,以适应各种尺寸和类型的金属材料,并在金属回收的高效加工和再利用中发挥重要作用。

鳄鱼式金属剪切机

一般剪切机在800mm、1000mm、1200mm,适合中小型废钢加工和回收点,需要人工卸料。优点是价格便宜,一般剪切机可以满足个体家庭、小型废金属回收站进行废钢加工处理。

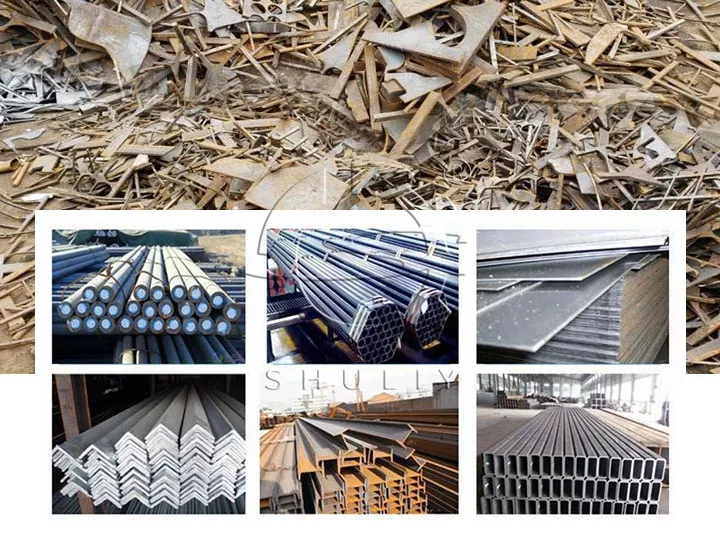

机器使用范围

液压金属剪切机是强大的金属剪切机,广泛应用于金属回收和加工行业。其使用范围包括但不限于以下内容:

- 废旧汽车拆解:可用于通过切割和分离汽车的金属部件,如车身、发动机和底盘,来拆解废旧汽车。

- 建筑和拆除废物处理:可以处理建筑工地和拆除项目产生的金属废物,如钢筋、梁和钢管。

- 金属加工厂:用于切割和加工金属材料,以满足不同的工程和制造需求。

- 管道和管材制造:用于切割和加工各种类型的金属管,以确保尺寸和质量的准确性。

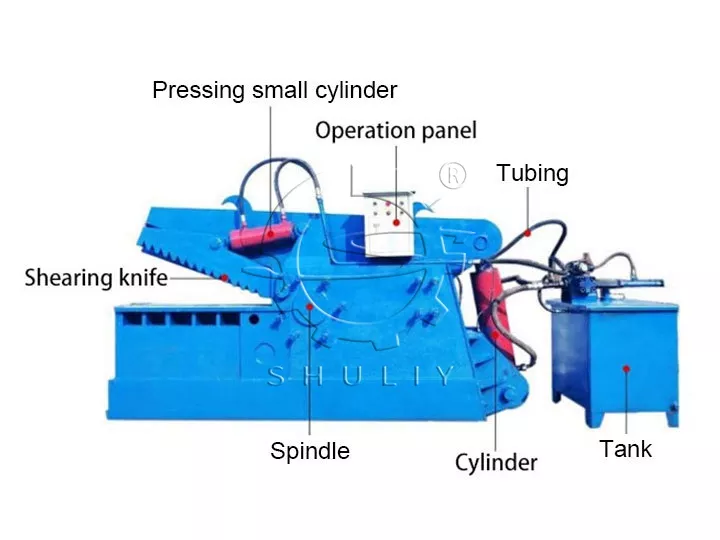

剪力主体结构

其主要结构包括机架、液压缸、刀片总成、液压系统、电气控制系统、剪切室等关键部件。剪切室、防护装置和安全装置、润滑系统。

技术参数

| 模型 | SL-1000A |

| 力量 | 7.5千瓦 |

| 最大物料压力 | 100吨 |

| 刀片长度 | 600毫米 |

| 最大开口尺寸 | 280毫米 |

| 最大频率 | 10-14分钟 |

虎头金属切割机

它具有压力大(一般350吨以上)、体积小、加工范围广、噪音低、剪切断面大、剪刀口调整方便等特点。

机器应用范围

- 废铁和铝回收:通常用于废铁和铝的回收过程,用于切割和加工小型金属零件、切屑和废料。

- 金属工艺产品制造:用于切割和加工轻金属材料,如家具、装饰物、金属零件等。

- 维修和维护:也常用于机械设备的维护,切割和修整金属部件,以保持设备的性能和功能。

- 废旧电器拆解:用于拆解和处理废旧电器和电子设备中的金属部件,如钢板、铝外壳等。

金属刀具结构

与鳄鱼剪的结构部件类似,这些主要结构部件协同工作,使其能够高效切割金属材料,适应广泛的切割需求。

常用技术数据

| 模型 | SL43-260 | SL43-315 | SL43-400 |

| 力量 | 260吨 | 315T | 400吨 |

| 力量 | 22千瓦 | 30千瓦 | 37千瓦 |

| 刀片长度 | 1200毫米 | 1200毫米 | 1200毫米 |

大的 龙门式金属剪

尺寸巨大,适合大型废钢回收站,效率高,剪切废钢量大,日产量30-90吨不等(不同型号产量和效率不同)。价格稍高,剪切效果好,节省人工,全自动操作。

适用范围

- 废金属回收:广泛用于处理大规模金属废料,如废旧汽车、废旧船只和废钢组件。

- 船舶拆解:可以切割和拆解废旧船只的金属部件,如船体、板材和舱室结构。

- 桥梁和隧道施工:在桥梁和隧道施工中,可以用于加工和切割桥梁组件、钢桩、隧道墙等。

- 冶金行业:在冶金行业中,可用于切割和加工在炼钢和铸造过程中产生的金属块和材料。

- 工程机械制造:用于大型工程机械和设备的金属加工,如挖掘机、装载机、推土机等。

这三种类型的金属剪板机主要部件相同,能够高效切割金属材料,适应多种切割需求。定期维护和保养是确保其性能和安全的关键。

机器参数

| 模型 | SLY-600T | SLY-800T |

| 最大切削力 | 600 | 800 |

| 系统压力 | ≤25Mpa | ≤25Mpa |

| 料仓尺寸 | 5500*1500*700毫米 | 6000*1700*800mm |

| 刀片长度 | 1600毫米 | 1800毫米 |

| 容量 | 8-10吨/小时 | 15-20吨/小时 |

| 剪切频率 | 4-6次/分钟 | 4-6次/分钟 |

| 力量 | 3*45千瓦 | 4*45千瓦 |

| 重量 | 30吨 | 38T |

总体而言,金属剪在回收行业中发挥着重要作用,通过提高效率、降低成本、减少废物量、提高资源回收率,为可持续金属回收和再利用做出贡献。

我们可以根据客户的不同需求推荐和定制机器类型,舒立生产的金属剪切机和破碎机种类繁多。类似的有大容量金属破碎机。如果您想了解更详细的信息,请随时与我们联系。