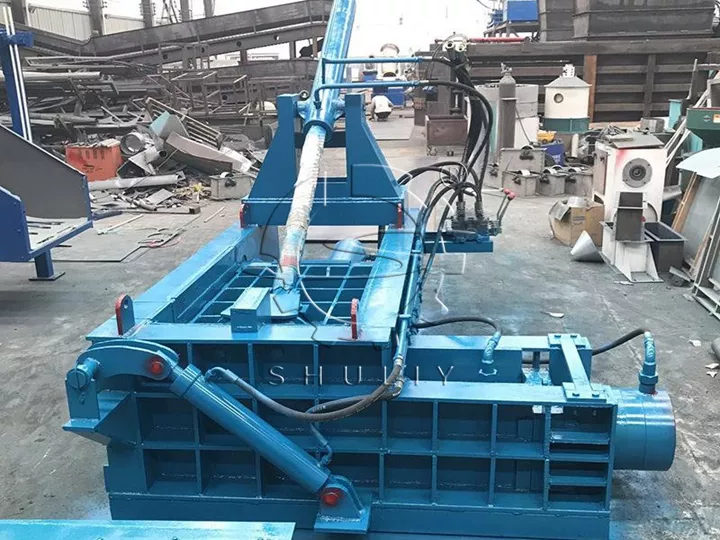

该卧式液压金属打包机能够将废金属、报废汽车及其他废金属压制成密度≥2200kg/m³的紧凑、均匀的金属块,显著减少了储存空间需求,并方便了运输和后续的冶炼回收。

该设备每小时可处理高达10吨的物料,运行平稳,占地面积小,操作简便。是废金属回收、加工和再利用的必备工具,能显著提高废金属加工效率并降低运输成本。

凭借其高效率和智能化操作,液压金属打包机已成为废金属回收站、钢厂及各类金属加工企业的必备设备,有助于提高生产效率并降低物流成本。

金属打包机的广泛应用

- 报废汽车拆解厂:压制汽车车身、发动机零件等废旧汽车部件。

- 建筑工地:压制钢筋、废旧金属框架等建筑垃圾。

- 金属回收厂:加工各类废金属,如废旧家电、废旧零件、废旧容器等。

- 制造企业:压制生产过程中产生的废钢、废铝、废铜等废料。

成品金属包的特点

- 易于储存:压缩后的金属块体积小,可整齐堆放,有效节省存储空间。

- 易于运输:整齐、紧凑的金属块降低了运输成本,提高了装卸效率。

- 易于再加工:金属块适用于后续的破碎、冶炼和深加工,实现资源的高效利用。

- 提高回收价值:标准化、高密度的金属包装可提高整体回收率,同时提升废金属的市场价值。

液压废金属打包机优点

- 运行平稳:设备采用低惯量、低噪音设计,确保操作灵活平稳,并提供可靠稳定的长期性能。

- 占地面积小:卧式紧凑结构设计非常适合空间有限的工厂和车间,同时也便于现场布局。

- 应用范围广:几乎可以压制所有类型的黑色和有色金属废料,包括钢、铜、铝等。

- 多种规格可选:可定制压力、料箱尺寸、打包尺寸和成型形状(例如矩形、八角形、圆柱形),以满足多样化的物料和用户需求。

- 操作简便:液电一体化智能控制系统,可实现单站启停、过载保护和故障报警。

- 高性价比:高压成型,节能高效,减少能源浪费和维护成本,同时显著提高生产效率。

废旧金属回收打包机是如何工作的?

在整个过程中,液压系统是关键驱动器,提供足够的力来压缩金属材料。同时,机械结构、刀片等部件也对确保金属能够均匀、高效地压缩和打包发挥着重要作用。

- 喂料:废金属原材料(如松散的金属片、废弃零件、旧家电等)被放入打包机的喂料口。

- 定位和压缩:材料被送入打包室进行定位,然后激活液压系统。液压缸强力推动压头或压板,将金属材料强压,并迅速将松散的金属压缩成一个密集的块。

- 捆绑和固定:当压缩到设定尺寸时,设备会自动或手动将金属块捆绑在一起,可以用钢丝或打包带固定,以防止块松动。

- 排放和收集:压块完成后,形成的金属块通过排放机制(例如,输送带、推送机制等)排出,并集中收集到存储区域或直接转移。

废金属回收机技术参数

我们工厂制造的金属打包机拥有高质量的零件,并提供 1 年保修。它具有专门定制的液压系统和电机。而在没有电源的地方,可以使用柴油机作为动力。以下是详细的技术参数,供参考。请随时与我们联系,我们帮助您选择合适的型号。

| 模型 | Y81-1250A | Y81-1600A |

| 公称力(kn) | 1250 | 1600 |

| 压缩室(mm) | 1200*700*600 | 1600*1000*800 |

| 块尺寸(mm) | 300*300 | 400*400 |

| 块体密度(kg/m3) | ≥2000 | ≥2000 |

| 产能(公斤/小时) | 1200-1800 | 2000-3500 |

| 单周期时间 | ≤120 | ≤120 |

| 功率(千瓦) | 15 | 22 |

| 卸包作业 | 推出、PLC控制配合 | 推出、PLC控制配合 |

成功案例

由于高效率、可定制性和低维护成本,我们的金属打包机回收设备已被发往多个国家,包括科威特、俄罗斯、博茨瓦纳、阿富汗、索马里、莫桑比克和乌干达。

下图是我们成功发往菲律宾的装货现场。该客户经营一家大型废金属回收公司,致力于废金属的有效处理和再利用。我们根据客户的需求设计机器。该客户购买了两台金属打包机。

我们的工厂还提供多种其他金属回收设备,例如金属压块机,以满足不同客户的多样化需求。我们致力于为您提供最佳解决方案,以提高您的回收效率。欢迎您的积极咨询,我们的专业团队将随时为您提供详细的产品信息和定制服务。