垂直液压纸板打包机是一种工业工具,通过80-200吨的超高压力将纸箱、塑料和金属废料等松散材料压缩至其原始体积的1/10。

它不仅解决了传统散装运输成本高和存储空间浪费等行业痛点,还实现了“一个机器多种功能”。从废纸板的常规捆绑到罐子的高密度压块,从纺织废料的回收再利用到工业废金属的预处理,只需简单调整压力参数,就可以适应20多种材料场景。

液压纸板打包机简介

液压打包机通常由压缩室、液压缸、控制系统、输送系统等组成。操作员将待加工的材料放入压缩室,控制系统启动液压缸施加压力,将材料压缩成包裹。

一旦压缩完成,包裹通常会通过输送系统进行输送或卸载,以便进一步存储或运输。液压打包机分为两种类型:垂直液压纸板打包机和水平液压纸箱打包机。

液压打包机的广泛应用

液压纸板打包机广泛应用于废物回收行业,将废纸、废塑料、废金属、废纤维及其他材料打包成紧凑的块,以便后续运输和回收。

- 造纸和纸浆工业:它们用于打包废纸和纸浆材料,以便运输到纸浆厂或造纸厂,用于制造再生纸浆和纸制品。

- 金属回收:用于压缩废金属,如废钢、废铝、废铜等,以便运输到金属回收厂进行再加工和冶炼。

- 塑料回收:液压纸板打包机可用于打包废塑料容器、瓶子和废塑料产品,以便运输到塑料回收厂进行回收。

- 纤维材料处理:在纤维产品行业中,它们用于压缩天然或合成纤维,如棉花、亚麻、羊毛等,以便可以用于制造纺织品和绝缘材料。

包装成品展示

液压纸板打包机的成品是经过打包和压缩的一包材料,通常呈正方形或长方形的块状结构。

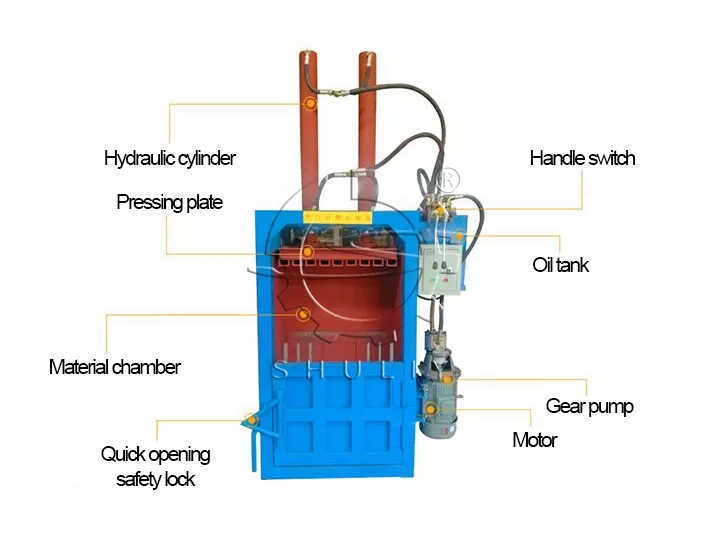

纸箱打包机主要结构

液压纸板打包机的主要结构通常包括以下几部分:

- 压缩室:它是液压打包机的核心组件,用于容纳和压缩待处理的废物或可回收材料。压缩室通常采用坚固的结构,以承受高压。

- 液压缸:它负责施加压力将废物压缩成块。液压缸通常由钢制成,具有高压流体输入和输出端口,通过液压油进行供给,以实现压缩操作。

- 液压系统:它由液压泵、油箱、液压管路和控制阀等组件组成,用于提供高压液体以驱动液压缸。该系统确保机器的高效工作和压缩操作。

- 结构框架:整个液压打包机通常安装在坚固的结构框架上,以提供稳定性和支撑。

纸箱液压打包机的结构和部件可能因制造商和型号的不同而有所不同,以满足不同应用的需求。

这些机器通常根据所处理的材料类型、压缩能力、自动化水平和其他因素进行定制。

总体而言,液压纸板打包机的构造是为了有效地将废物和可回收材料压缩成块,以便存储、运输和回收。

液压打包机工作流程

液压纸箱打包机的工作原理可能因机器型号和所处理的材料而异,但上述步骤是其基本操作原理的总体概述。这些机器的设计和性能将根据应用的需求而变化。

喂养

待处理的废物或可回收材料通过传送带、手动装载或其他方式进入打包机的进料区域。

压缩室负载

操作员将原材料放入液压纸板打包机的压缩室中。这个压缩室通常是一个开放的容器,可以容纳一定量的废物。

液压系统工作原理

液压打包机的关键部分是液压系统,由液压缸、泵、油箱、控制阀等组成。液压系统提供高压液压油,通过液压缸施加压力,将原料压缩成致密的块状。

压缩过程

液压缸将向下移动,对废物施加恒定压力,将其压缩成块。该过程可能会持续一段时间,具体取决于所加工的材料和设备的设计。

成品排放

一旦压缩完成,成品通常会从打包机的排料口排出。这些成品封装通常为方形或长方形块体,结构紧凑。

液压打包机的优点

- 它们可以将废物和可回收材料压缩成整齐的块,这不仅节省空间,还降低了存储和运输成本。

- 这些机器也非常注重效率。液压纸板打包机可以自动运行,使废物处理更快,并有助于降低人工成本。

- 液压打包机最好的特点之一就是它们的多功能性。它们可以处理各种材料,从废纸和塑料到金属、木材、织物等。

- 此外,它们是可定制的!您可以根据不同应用的具体需求调整液压打包机的大小、容量和功能。

纸板打包机主要技术数据

| 模型 | SL40QT | SL60QT | SL80QT |

| 液压动力 | 40吨 | 60吨 | 80吨 |

| 包装尺寸(长*宽*高) | 720*720*300-1600mm | 850*750*300-1800mm | 1100*800*300-2000mm |

| 进料口尺寸(L*H) | 1000*720毫米 | 1200*750毫米 | 1500*800mm) |

| 草捆密度 | 300公斤/立方米 | 350公斤/立方米 | 400公斤/立方米 |

| 捆包线 | 4线 | 4线 | 4线 |

| 能力 | 1-3吨/小时 | 2-4吨/小时 | 4-7吨/小时 |

| 捆包钢丝 | 12#*4个 | 12#*4个 | 12#*4个 |

| 力量 | 18-22KW/24-30HP | 22-30千瓦/30-40马力 | 30-45千瓦/40-60马力 |

| 机器重量 | 约8吨 | 约10吨 | 约13吨 |

对于其他需要处理的原材料,我们有废旧衣物打包机和金属打包机可供选择。如果您想获取更多类型和型号的技术参数,请随时与我们联系。