蛋托生产线包括纸浆制造系统、纸浆模塑机、干燥机、包装系统。这个过程展示了如何利用废纸来制作环保、耐用且价格实惠的蛋托盘。由于这些特点,超市、餐馆和家庭对鸡蛋托盘储存和运输鸡蛋的需求量很大。

在这篇文章中,我们将详细介绍完整的蛋托生产流程,包括所需的设备和材料。此外,我们还提供优质设备和各种纸托盘制作解决方案。如果您有兴趣开展蛋托制造业务,请随时与我们联系!

蛋托生产线原料

蛋托的主要原料是废纸,取材方便,价格低廉。这通常包括废报纸、废纸板和纸板箱等包装材料。

最好保证废纸干净、无污染物、厚度均匀。

水是制备纸浆的另一种重要材料。拥有可靠、未受污染且质量稳定的水源至关重要。

最终产品展示

经过一系列的蛋托生产线,终于可以得到质轻、坚固、吸湿性好的环保蛋托。另外,制作蛋托的成本低,经济。可以生产各种尺寸和形状的纸托盘,以适应不同尺寸和类型的物品。

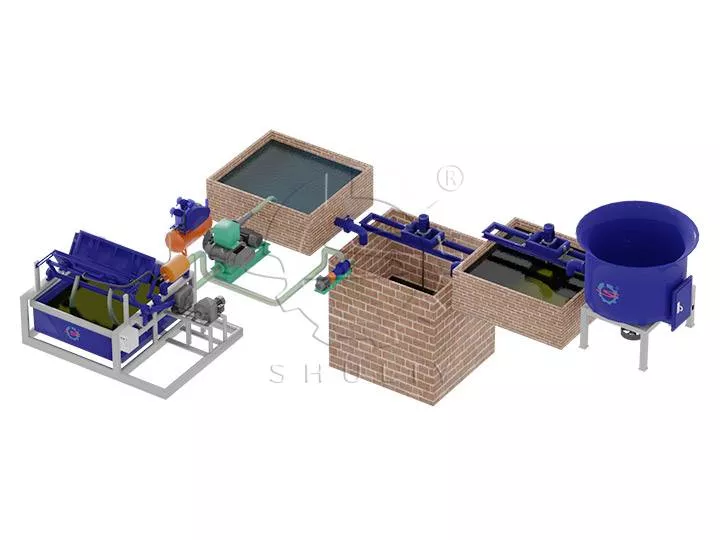

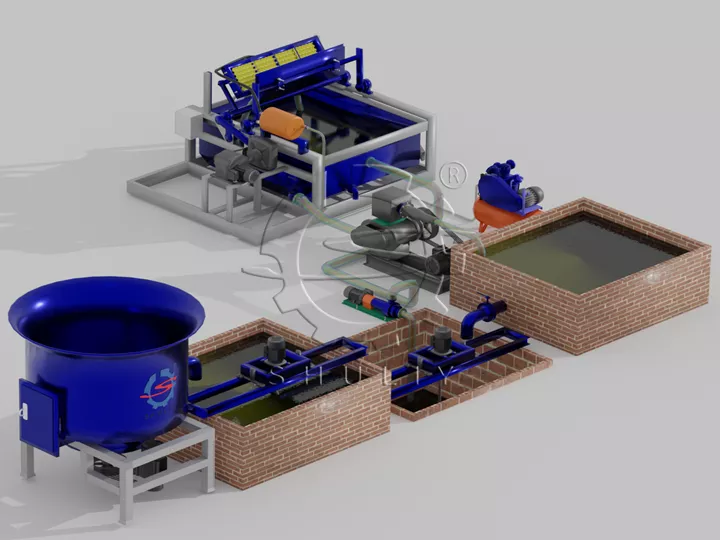

蛋盒制造厂工作流程

The whole egg tray production line workflow is automated. It includes the following series of machines: pulper machine → egg tray forming machine → drying machine → egg tray baler.

其中打包机为可选设备,您可以根据情况选择是否购买。

另外,还可以选择蛋托热压机,这样可以让蛋托表面更加光滑,更好卖。

纸托盘制造主机

根据客户对生产能力和产品尺寸形状的需求,我们生产蛋托生产线中每台机器的不同型号。告诉我们您的需求,我们将为您推荐最好的机器。

纸浆机

The pulper machine disperses and evenly mixes the fibers of the pulp through agitation, and then removes impurities through screening. This allows the pulp to reach the proper consistency and viscosity.

通常只需一名工人即可将废纸和水按照1:3的比例放入机器中。如果想改变蛋托颜色,可以在这里添加着色剂。该工艺为后续工艺提供了基础材料。

纸浆模塑蛋托制造机

纸浆首先被输送至成型机。然后使用浆槽将其均匀地铺在模具表面,以确保纸浆分布均匀。

Depending on the mold used, the egg tray forming machines can produce trays of different sizes. The forming process is automated, ensuring consistency and uniformity of the trays produced.

烘干机

干燥机可快速去除已成型至所需干燥程度的蛋托产品中的水分。此过程对于确保蛋盘坚固且能够承受鸡蛋的重量是必要的。

干燥蛋托的方法有多种,具体取决于生产规模、可用资源和气候。

我们有连续多层蛋塔烘干机、烘干房、砖窑烘干三种类型的烘干设备可供选择。

蛋托打包机

蛋托打包机能将蛋托按照设定的规格和堆放方式自动整齐有序地包装,以便储存、运输、销售。

不仅提高了包装效率,而且保证了产品的整体质量和外观。

蛋托热压机

蛋托热压机通过加热并施加一定的压力,使已经成型的蛋托表面变得更光滑、更坚固、更坚固,从而更好地销售。

这也有助于确保蛋托产品在运输、储存和使用过程中不易变形或破裂。

蛋托机技术参数

蛋托生产线机器专为大批量生产纸托盘而设计,产量取决于机器的尺寸和设计。已开发出不同型号的蛋托机,可处理 1,000 至 7,000 个纸托。以下是主要参数供您参考。

| 模型 | 容量 | 纸张消耗量 | 用水量 | 使用的能源 | 工人 |

| SL-3*1 | 1000-1500片/小时 | 120公斤/小时 | 300公斤/小时 | 32千瓦/小时 | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160公斤/小时 | 380公斤/小时 | 45千瓦/小时 | 3-4 |

| SL-3*4 | 2000-2500片/小时 | 200公斤/小时 | 450公斤/小时 | 58千瓦/小时 | 4-5 |

| SL-4*4 | 3000-3500片/小时 | 280公斤/小时 | 560公斤/小时 | 78千瓦/小时 | 4-5 |

| SL-4*8 | 4000个/小时 | 320公斤/小时 | 600公斤/小时 | 80千瓦/小时 | 5-6 |

| SL-5*8 | 5000个/小时 | 400公斤/小时 | 750公斤/小时 | 85千瓦/小时 | 3-4 |

| SL-5*12 | 6000个/小时 | 480公斤/小时 | 900公斤/小时 | 90千瓦/小时 | 3-4 |

| SL-6*12 | 8000个/小时 | 640公斤/小时 | 1040公斤/小时 | 100千瓦/小时 | 3-4 |

舒利蛋托生产线的优点

- 经验丰富的供应商: Shuliy Group 已涉足该行业多年,已在全球范围内成功安装和运行了 100 多条蛋托生产线。我们丰富的出口经验有助于节省您的时间和金钱。

- 多种选择和定制设计: 首先,我们提供各种型号的蛋托机。其次,您可以定制蛋托模具来制作不同的托盘。第三,同一台机器可以生产不同类型的托盘。

- 出厂价,成本低: 我们有自己的工厂,所以我们可以为您提供公平的价格。此外,我们还提供根据您的需求量身定制的最合适的解决方案,以帮助您降低成本和运营费用。

- 环保无污染: 整个蛋托生产过程不产生废水、废气。所有水均被循环利用。蛋托机将废纸回收制成可生物降解的纸浆模塑产品。

纸浆模塑纸托盘生产线成功案例

蛋托生产线已成为一种高效、环保、经济的生产方式,逐渐在蛋品包装行业得到广泛应用。

Our machine products are exported all over the world and have been successfully shipped to many countries, including but not limited to Cameroon, Mozambique, United Kingdom, Uzbekistan, Senegal, the United States, Canada, Kenya, Zimbabwe, Indonesia, Nigeria, and so on.

If you have any questions about the process of making egg trays, you can click the article: Reveal The Whole Process Of Egg Tray Molding Production. If you would like more detailed information, please contact us at any time.