Waste textile recycling machines typically consist of two core components: an opening machine and a cleaning machine. Through close collaboration, these units achieve efficient processing of waste fabrics and fiber regeneration. The opener machine is responsible for opening, dispersing, and combing waste textiles, separating tangled fabric fibers into processable fiber bundles.

The cleaner machine further removes impurities and non-fibrous components, restoring the fibers to a reusable state. When integrated with fabric cutting equipment, this system efficiently converts various types of waste textiles into renewable fiber materials, providing a robust foundation for textile recycling.

applications of waste textile recycling machine

Waste textile recycling machines have a wide range of applications in the field of textile waste treatment and reuse. The following are its main application areas:

- Textile waste recycling: applicable to various textile waste materials including used clothing, discarded fabrics, and waste bedding.

- Fiber regeneration: through specialized processing, fibers from discarded fabrics are restructured into usable fiber forms suitable for spinning, weaving, and other textile manufacturing processes.

- Remanufacturing applications: recovered fiber materials can be extensively utilized in the remanufacturing of new textile products, including apparel fabrics, carpets, industrial textiles, and other textile goods.

fiber opening machine

Openers are an important piece of machinery and equipment in the waste textile recycling machine industry, equipped with only one roll whose main role is to pre-treat the fiber raw materials (e.g., cotton, wool, synthetic fibers, etc.) for pre-treatment to facilitate the subsequent spinning and weaving process. The following are some of the key features and functions of the openers:

- Combing and separating fibers: openers unravel, disperse, and align the fiber raw material into a single stream of fibers through a series of combing and separating processes. This helps to eliminate tangles and mixing between fibers and keeps the fibers in a parallel arrangement.

- Removal of impurities and short fibers: the opener removes impurities, dust, and short fibers from the fibers, improving the quality and uniformity of the fibers.

- Adjustment of fiber length: these machines can adjust the length of fibers as needed to meet the requirements of different spinning and weaving processes.

- Improve spinning efficiency: by pre-treating fibers, openers can improve the efficiency of subsequent fiber cleaning machines and reduce yarn breakage and production problems.

Openers play a key role in the textile industry by helping to ensure the quality and consistency of fibers, which in turn affects the quality and performance of the final textile. These machines are used in a wide range of applications in the textile manufacturing process and are important for the development of the textile industry.

Textile fiber cleaning machine

An elasticity cleaning machine is an important piece of equipment in the waste textile recycling machine industry, whose main function is to further process the fibers, equipped with multiple rollers to remove the foreign matter and short fibers from them, to improve the quality and suitability of the fibers. The following are some of the key features and functions of the bomb cleaner:

- Removal of foreign matter and impurities: bullet Cleaning Machines remove impurities, dust, and other foreign matter from fibers through various physical and mechanical processes such as vibration, screening, and airflow separation. This helps to improve the cleanliness and purity of the fibers.

- Separation of short fibers: waste textile recycling machines identify and separate short fibers from fibers, which often interfere with the weaving and spinning process, and removing them helps to improve product quality.

- Improve fiber uniformity: the clearer arrangement of the fibers into a more uniform state, reducing mixing between fibers and differences in fiber length.

Playing a vital role in the textile industry, clearing machines help ensure the quality and consistency of fibers, improving the productivity and final quality of textiles. These machines play an important role in the growth and sustainability of the textile industry.

workflow of textile fiber recycling process

Openers and cleaners are two key pieces of equipment in waste textile recycling machines, and they play an important role in the fiber pretreatment process. The following is their working principle:

Working principle of the openers

- Feeding and dispersing: the openers first feed waste textiles into the machine, usually in the form of rolls or bales. The machine loosens and disperses these textiles.

- Combing: next, the textiles are conveyed into a series of carding devices, which consist of rotating comb teeth. The comb teeth will unravel, disperse, and arrange the fibers into a single fiber stream.

- Removal of impurities: during the carding process, the opener automatically removes impurities, dust, and short fibers to improve the quality and cleanliness of the fibers.

- Separation of short fibers: the opener also detects and separates short fibers from the fibers, which helps to reduce fiber mixing and yarn breakage problems in subsequent processes.

- Output: the treated fiber stream is conveyed to the next processing step, usually a clearer or other further processing equipment.

Operation of the cleaner

- Input: the clearer receives the fiber stream from the opener, the fibers in this stream have usually already been preliminarily separated and carded.

- Cleaning and Separation: the waste textile recycling machine uses physical processes such as vibration, screening, and airflow separation to clean and separate the fibers. This helps to remove residual impurities, dust, and short fibers.

- Output: the cleaned fiber stream is conveyed to the next processing step, such as spinning or a line for preparing recycled textiles.

Overall, the main task of the openers is to disintegrate, disperse, and remove impurities from the waste textiles, while the cleaners further clean and purify the fibers to ensure the quality of the final fiber material. The combined action of these two machines contributes to the quality and availability of recycled textiles.

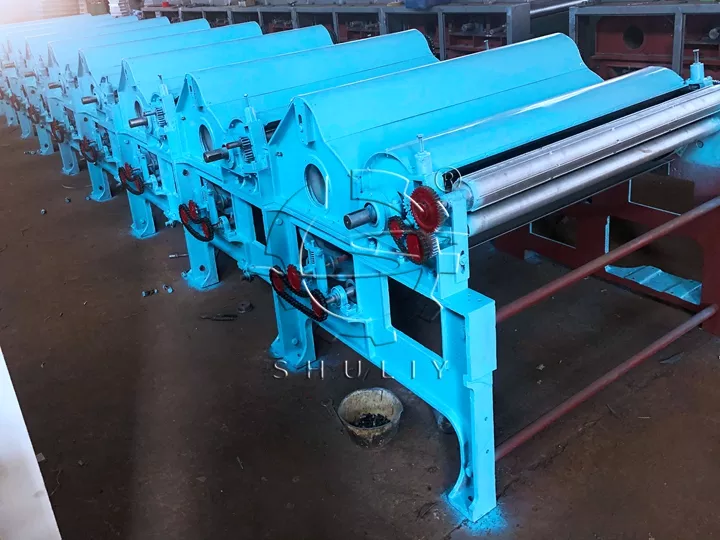

Fiber recycling Machines with covers

To better put dust and pollution prevention in the process of waste textile recycling machine work, as well as to ensure that the machine is usually cleaner and save cleanup, we can make the machine equipped with an outer cover, the factory picture is as follows:

specifications of waste Fabric recycling machine

| Model | Size | Output | Discharge | Speed | Diameter roller | Power | Weight | Chain | Flat belt |

| GM-600 | 2600*1550*1300mm | 180-220kg / h | 30% – 40% | 1040 rpm | 500mm | 18.5kw | 1T | 19.5mm | 2000*1020*4-layer line |

| Name | Dimension | Motor | Roller’s Length | Roller’s Diameter | Weight | Capacity |

| One roller | 2000*1700*1300mm | 11kw | 1000mm | 250mm | 800kg | 150-250kg/h |

| Double Roller | 2900*1700*1300mm | 29kw | 1000 mm | 250mm | 1500kg | 150-250kg/h |

| Three roller | 4000*1700*1300mm | 34kw | 1000mm | 250mm | 2350kg | 150-250kg/h |

| Four roller | 5100*1700*1300mm | 40kw | 1000mm | 250mm | 3200kg | 150-250kg/h |

Before using these two waste textile recycling machines, you can use a fiber cutting machine to pre-process the waste fabric. For details, click Textile Fiber Cutting Machine In Waste Recycling Line. At the same time, the finished product after opening can be processed into pillow products by a fiber pillow filling machine.

If you want to know more about the models and types of waste textile recycling machines, or you are interested in the fiber recycling machines, please feel free to contact us!