Our company has recently completed the production of two waste plastic recycling machines and shipped them to Kenya. This order features a 60-type multifunctional plastic crushing and cleaning machine, along with a 120T vertical hydraulic baler, both of which will significantly enhance the customer’s production efficiency.

Customer background and demand analysis

The Kenyan customer who made this purchase is focused on recycling and processing waste plastic bottles. As global standards for plastic waste treatment become more stringent, there is an urgent need for more efficient and automated equipment to meet increasing business demands.

They manage a significant volume of waste plastic bottles daily and have elevated expectations for the crushing, cleaning, and packaging stages of the recycling process. By choosing our waste plastic recycling machines, customers aim to enhance overall production efficiency, lower labor costs, and ensure that the packaged plastic bottles are easy to transport and store.

Waste Plastic Recycling machines’ uses and advantages

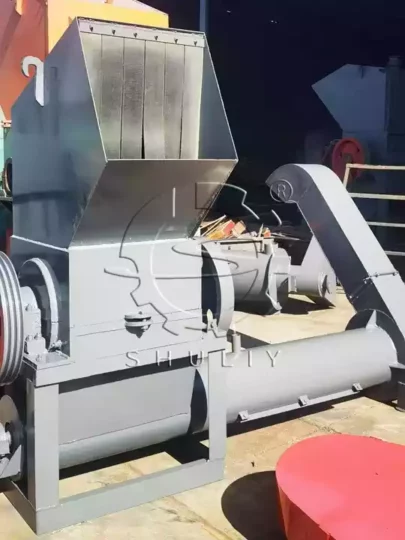

60-type multifunctional plastic crushing and cleaning machine

This plastic crusher machine is designed to crush and clean waste plastic bottles, making it an effective tool for recycling. Its primary function is to crush these bottles while automatically cleaning them in the process, which streamlines the recycling of waste plastics.

By minimizing the steps involved, this equipment enables customers to recycle resources efficiently, saving both time and costs in production. Additionally, it comes with 10 spare crushing knives made of 9CrSi, ensuring stable long-term operation and catering to the needs of customers requiring large-scale processing.

120T vertical hydraulic baler

This hydraulic baling equipment weighs 3 tons and is specifically designed for the large-scale packaging of waste plastic bottles. The dimensions of the baling block are 1150*850*900mm, allowing it to pack approximately 270 kilograms of plastic bottles, demonstrating impressive compression capabilities and significantly enhancing space utilization.

This equipment offers considerable benefits for customers requiring long-distance transportation or supplying local recycled plastic companies, as it can lower transportation costs and simplify inventory management. Additionally, the baler comes with a set of spare oil seals to maintain equipment stability during prolonged high-load operations, thereby extending the machine’s service life.

Customer expectations and equipment value

The two pieces of waste plastic recycling machine acquired this time not only fulfill the customer’s requirements for effective plastic recycling and processing but also reflect their strategy for future business growth.

- With the introduction of the 60-type multifunctional plastic crushing and cleaning machine, customers can achieve automated operations for crushing and cleaning waste plastics, significantly enhancing production efficiency.

- The robust compression capacity of the 120T vertical hydraulic baler allows for easy packaging of plastic bottle blocks, making them ready for export to international markets or for use by local recycling facilities, thereby further advancing the efficient recycling of waste plastics.

When selecting equipment, customers also prioritize long-term durability and ease of maintenance. The inclusion of multiple spare parts, such as crushing blades and oil seals, highlights the customer’s need for continuous operation and efficient production. The equipment’s stability and high-performance efficiency will generate ongoing economic benefits for customers and support Kenya‘s local resource recycling industry.