Plastic crushers shred plastic bags/films, plastic bottles, fabrics, etc. through a high-speed rotating blade or cutter system, which effectively reduces the volume of plastic waste and is used to make another plastic product from existing plastics. The output of this machine can reach more than 1t/h. By replacing the screen mesh with different size holes, different particle-size products can be obtained.

wide applications of waste plastic crusher

The PP PE flakes shredding equipment can be used for crushing and recycling all waste plastics. This includes PVC, TPR, PET, TPE, EVA, PP, PE, and PC materials such as boxes, thin pipe fittings, blow-molded parts, bottles, shells, life plastic supplies, etc. It can also be used as an auxiliary machine for injection molding machine to re-crush its sprues or inferior parts for reuse.

Replacement of knives, the gap between the movable knife and the fixed knife: 20HP (15kw) above the crusher 0.8MM is good, and 20HP below the crusher 0.5MM is good. The thinner the recycled material, the gap can be adjusted appropriately.

finished products you can get

By using our machines, you can get finished products with uniform particles, high quality, and controlled particle size. The crushed plastic granules can be used to produce plastic products again, realizing the recycling of resources.

plastic shredding machine’s main structure

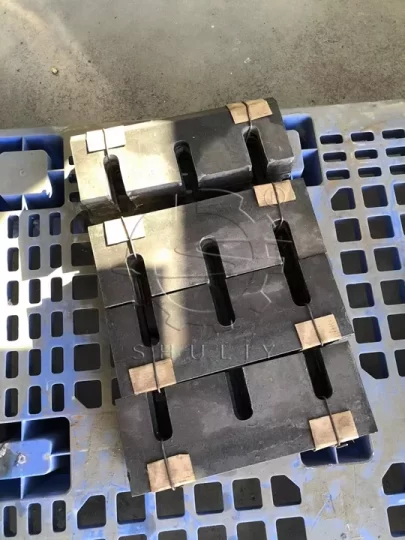

The main structure of the plastic pulverizer includes blades and screens, both of which can be customized. Reasonable selection and configuration are important factors in ensuring the efficient work of the plastic crusher, which can be adjusted according to different crushing requirements to improve the flexibility and applicability of the equipment. The blade material is configured by the raw material you want to process.

- 9Cisi, chrome steel: suitable for general plastic parts and engineering plastics.

- SKD-11: suitable for crushing harder plastic materials, and thicker and heavier rubber blocks.

- SKH-9: also suitable for crushing softer rubber and plastics such as foam, plastic bags, films, and fiber materials.

The relationship between the size of the crushed flakes and the crusher screen is very important. The smaller the mesh, the finer the particles that pass through. Therefore, if you need smaller flakes, you should choose a crusher with a smaller screen mesh. If you want large flakes, you need to choose a crusher with a larger screen mesh. 12, 16, and 20 mm are the most common screen sizes. The larger the screen size, the higher the crushing output, and the smaller the screen size, the lower the crushing output.

how the plastic crushing machine works?

The plastic grinding machine cuts, tears, and crushes the large plastic products put into the feeding port through the high-speed rotating blade system. The strong shearing and tearing action of the blades makes the plastic raw materials gradually become small particles, and then the size of the particles is controlled through the sieve and the final output of plastic particles meets the requirements.

Plastic grinder supporting equipment

A knife sharpening machine can grind and repair the blades of a plastic recycling crusher to ensure that the blades remain sharp and in good working condition.

As the plastic pulverizer is used, the blades will gradually wear out, while the knife grinder restores the cutting ability of the blades and prolongs their service life through a professional grinding process.

plastic film shredder machine benefits

- Adopting special alloy steel material blade, high cutting speed, durable and wear-resistant blade.

- The front and rear walls of the crushing chamber adopt double-layer sound insulation, with low noise.

- Strong cutting force, high productivity, large crushing ratio, and even fragment size.

- Separation of feeding hopper, crushing chamber, and screening hopper, easy loading and unloading.

- Special design of the crushing chamber, no hopper, large feeding opening, and convenient loading.

technical data of plastic crusher

The size of the crusher’s feed opening and the dimensions of the crushing chamber inside it determine its capacity. As a general rule, crushers with larger feed openings can crush larger pieces of material. Crushers with smaller feed openings will have a reduced capacity. If you need to process large pieces of material, you need to choose a crusher with a larger feed opening.

The following parameters are the basic data of some models of plastic crusher recycling machines, we can design different models and appearance according to your special needs.

| Model | SLSP-600 | SLSP-800 | SLSP-1000 |

| Capacity | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Motor Power | 30kw | 45kw | 55kw |

| Material of Knives | 60Si2Mn | 60Si2Mn | 60Si2Mn |

| Number of Knives | 10pcs | 10pcs | 10pcs |

| Box Width | 600cm | 800cm | 1000cm |

How To Choose The Right Plastic recycling crusher?

The first thing you need to do is determine the material you want to shred and the size of the finished product you want. There are many different types of plastic shredders on the market, each designed for a specific purpose.

For example, some are designed for processing hard plastic waste (PET plastic bottles or HDPE plastic barrels), some can process soft plastic waste and even films, while others can shred all kinds of PP, PE, and PVC pipe plastic waste.

In the plastic recycling industry, this machine is usually used for plastic washing and granulation recycling lines. For details, please click PET Bottle Crushing And Washing Recycling Line and HDPE PP PS Hard Rigid Waste Plastic Pelletizing Recycling Line.

successful cases

Our plastic crushers are popular all over the world and have been successfully exported to more than 30 countries including the United States, Germany, Japan, China, India, Brazil, Mexico, Ethiopia, Mozambique, Cote d’Ivoire, Congo, Australia, Canada, and Nigeria, helping customers achieve sustainable development and economic benefits.

our service

- We have a team of experienced engineers and technicians who can help you choose the right shredder for your needs.

- We also have a complete service team to help you solve any problems you may encounter, including transportation, importing, training employees on how to use, etc.

- If you encounter technical problems, you can contact our technical team without hesitation to troubleshoot and solve the problem.

- In addition, we have a large number of parts in stock in our factory for your daily replacement. Whether it is a blade, screen, or other parts, we can ship it within 3 days.

If you are interested in our plastic crusher, please feel free to contact us. We will provide you with more detailed pictures, videos, and other information and look forward to serving you.