The textile fiber cutting machine is primarily used to cut various fiber materials—such as waste textiles, glass fiber, aramid fiber, and fabric scraps—into desired lengths for subsequent reprocessing and reuse.

This equipment delivers sharp cutting with controllable length, significantly enhancing fiber recovery rates. It also supplies high-quality raw materials for downstream processes like carpet manufacturing, felt production, and compression baling.

As a vital piece of equipment for modern textile waste recycling and regeneration, it finds extensive application across industries including textiles, chemicals, and new materials.

Raw materials that can be processed

Textile fiber cutting machines are typically used to process a variety of fiber materials, including but not limited to the following types of raw materials:

- Waste textiles: including discarded clothing, bedding, towels, fabrics, etc.

- Fiber waste: such as leftover fibers from the textile industry, cutting waste, etc.

- Paper and cardboard, plastic sheets.

- Rubber: rubber hoses, rubber belts, etc.

- Metal wires, synthetic fibers.

- Other cellulosic materials: e.g. bamboo, wood fibers, flax, etc.

Please note that different models and configurations of textile fiber cutting machines may be suitable for different types of raw materials, and specific application requirements may require the selection of the appropriate machine type and tool configuration.

fiber waste cutting machine finished products show

Textile fiber cutters can efficiently and accurately shear waste fiber materials to the desired length, ensuring that the output is uniform and consistent. These cut fiber blocks usually have a compact shape for easy subsequent handling and transportation.

functions of textile fiber cutting machine

- Fibers can be cut to varying lengths as needed to meet raw material specifications for diverse industrial applications.

- It processes waste fabrics, textile scraps, and waste fibers into suitable lengths for recycling.

- As front-end equipment in fiber recycling lines, it supplies suitable raw materials for subsequent processes like pulverization, pelletization, and baling.

- Supports automated or semi-automated operation for high-volume rapid cutting, reducing manual labor intensity.

- Transforming waste fibers into reusable secondary raw materials helps conserve resources, lower production costs, and advance the green circular economy.

Fabric cutter machine advantages

- High-efficiency sharp cutting: utilizes a premium blade design for clean cuts with minimal fiber scattering.

- User-friendly operation: intelligent design with adjustable parameters enables quick mastery by diverse users.

- Versatile application: processes various materials including cotton fibers, synthetic fibers, glass fibers, and aramid fibers.

- High automation: supports continuous feeding and cutting, significantly boosting production efficiency.

- Energy-efficient and eco-friendly: recycles waste fibers into usable resources, reducing environmental impact and aligning with sustainable development goals.

- Robust and durable: sturdy construction with wear-resistant core components ensures long-term stable operation.

These features make textile fiber cutting machines an important tool in the fiber recycling and reclamation industry, helping to reduce the amount of waste, reduce resource waste, and promote environmental protection and sustainability.

working principle of fabric waste shredder machine

Textile fiber cutting machines utilize sharp cutting tools to precisely shear the fiber material to obtain the desired length and shape for different industrial applications. The process is usually efficient, precise, and somewhat automated, contributing to increased productivity and resource recovery.

Feeding and Positioning

First, the fiber materials to be processed (e.g., waste textiles) are fed into the machine through the feeding system. Usually, these materials are positioned in the cutting area.

Shearing process

The textile fiber cutting machine is equipped with sharp blades or cutting tools that can shear the fibrous material at high speed. Typically, these blades can be adjusted as needed to ensure the desired length.

Length Control

Precise control of the cut fiber length can be achieved by adjusting the position of the blades or regulating the speed of the machine.

Collection and Handling

Once the fibers have been cut to the desired length, they can be collected and handled for subsequent processing steps, such as fiber shredding, baling, and so on.

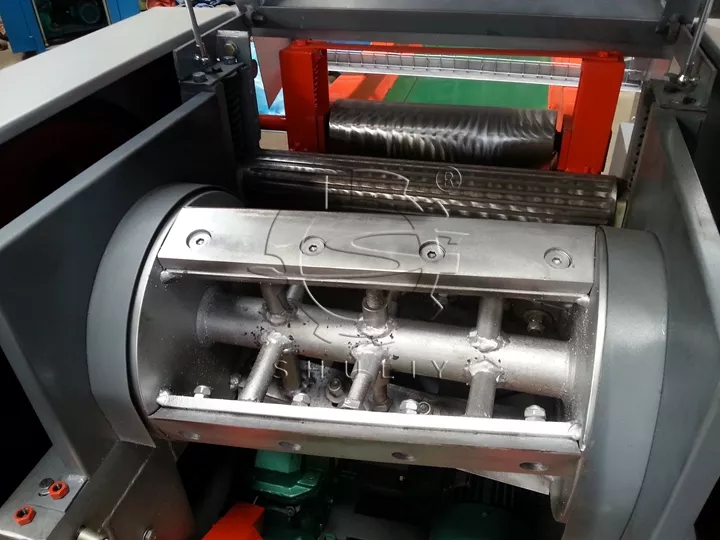

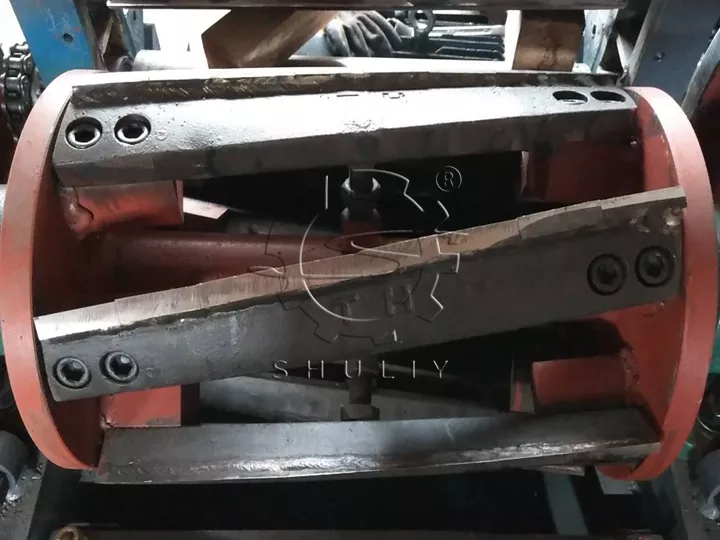

Matching wearing parts of fiber recycling machine

The cutter has two fixed blades and four movable blades, and the blades are made of alloy tool steel.

According to the requirements of different fineness and sizes of finished products, we are equipped with different knife rollers and blades. To prevent the knives from becoming dull, you can remove zipper buttons, etc. from clothes.

parameters of textile fiber shredding machine

The technical parameters of a fiber-cutting machine can vary depending on the model and manufacturer, here are some common parameters for three hot models:

| Model | SL-800 | SL-1200 | SL-1600 |

| Capacity | 300-500kg/h | 300-500kg/h | 1000-3000kg/h |

| Power | 7.5+1.5kw | 15+1.5kw | 18.5+3kw |

| Cut size | 3-15cm(Regular size) | 3-15cm(Regular size) | 3-15cm(Regular size) |

| Cut thickness | 30-80mm | 30-80mm | 30-70mm |

| Dimension | 2150*1250*1360mm | 3200*1000*1200mm | 7000*1800*1950mm |

If you want to get more detailed information, please feel free to contact us!

packaging and shipping of fiber cutters

Our textile fiber cutting machines are shipped to various countries, especially in areas with high demand in the textile and waste recycling sectors. The following are the countries that often receive fiber cutters for export: India, Vietnam, Bangladesh, Brazil, Egypt, Mexico, Turkey, Thailand, and Russia.

These countries usually have a large textile, waste recycling, or resource recovery industry and therefore have a relatively high demand for fiber cutters. Such machines play a key role in the field of fiber recycling and regeneration and help in converting waste fiber materials into usable recycled raw materials.

There is a global market for textile fiber cutting machines and the exact export destination will depend on the manufacturer’s marketing strategy and customer needs.