Maskinen för plastpelletisering, även kallad plastgranulator, är en oumbärlig utrustning i processen för återvinning och återanvändning av plastavfall. Med speciell skruvdesign och olika konfigurationer är denna utrustning lämplig för regenerativ granulation och färgblandningsgranulation av PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PET, PMMA och andra plastmaterial.

Både industriavfall och jordbruksplastrester kan effektivt bearbetas och omvandlas till återanvändbara pelletiserade råmaterial, som är allmänt använda vid omtillverkning av plastprodukter. Vi erbjuder flexibla anpassningsalternativ, låg energiförbrukning och en förenklad driftsprocess. Hela uppsättningen av utrustning kan hanteras av bara 1-2 personer, vilket hjälper företag att spara kostnader och förbättra effektiviteten.

matumizi ya mashine ya plastiki pelletizing

Mashine hii ni bora kwa watayarishaji wa filamu za ufungaji wa chupa za vinywaji, mifuko ya biashara, mifuko ya takataka, filamu ya kilimo, ufungaji wa chakula, filamu ya kupungua na kunyoosha, pamoja na mifuko ya PP ya kusuka na wazalishaji wa mifuko ya jumbo katika sekta ya kusuka.

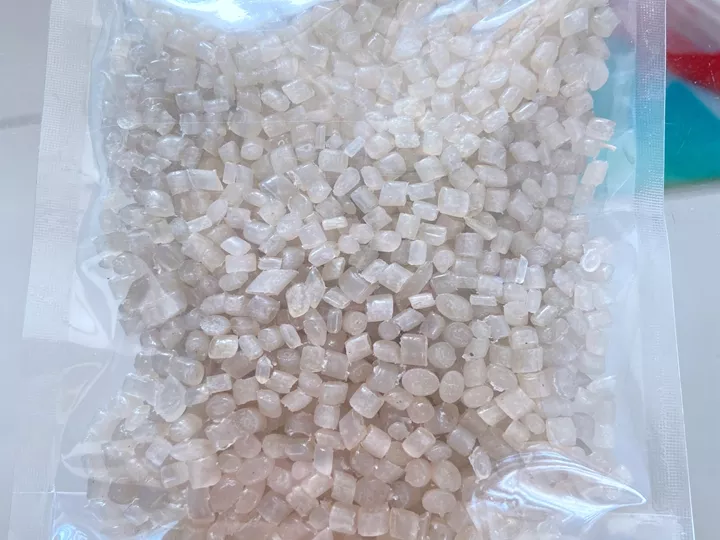

bidhaa ya mwisho kutoka PP PE granule extruder

- Granulerna är enhetliga i form och storlek, med slät yta och inga grader.

- Densiteten hos granulerna är måttlig, med utmärkta fysikaliska egenskaper, såsom hög styrka, slitstyrka och korrosionsbeständighet.

- Ingen behov av kylning och torkning, den rengjorda plasten kan granuleras direkt, vilket förenklar arbetsprocessen.

- Genom att använda elektromagnetisk uppvärmning och automatisk temperaturkontrollteknik, sparar energi och undviker sekundär förorening.

- De återvunna pellets som produceras kan användas till 100% i tillverkningen av nya produkter, med hög återvinningsgrad och goda ekonomiska fördelar.

faida za mashine ya plastiki ya granulator

- Det kan hantera ett brett spektrum av allmänna och ingenjörsplaster för att möta olika återvinningsbehov.

- Med intermittent uppvärmningsfunktion minskas den totala energiförbrukningen med cirka 20%, vilket sänker driftskostnaderna.

- Skruven och cylindern behandlas med speciell härdning, slitageskydd och lång livslängd.

- Genom att använda högmoment växellådsdesign, körs den smidigt utan bullerförorening.

- Hög grad av automatisering, endast 1-2 personer krävs för att driva, vilket minskar arbetskraftsinvesteringen.

- Tillhandahåll olika skruvstrukturer och konfigurationsprogram enligt materialegenskaper för att säkerställa granuleringseffekten.

- Den dagliga bearbetningskapaciteten kan nå 20~30 ton, vilket kan möta massaproduktionen av medelstora och stora plaståtervinningsfabriker.

vifaa vya kusaidia pelletizer ya plastiki

Maskinen för plastpelletisering måste användas tillsammans med en kross, en tvättmaskin och sedan en plastgranulatklippare. Rengöring och torkning av avfall av plast är det första steget i återvinning.

Därefter smälts den rena plasten och plastifieras genom skruvextrudern i plastpelletmaskinen och extruderas i remsor. Efter att ha svalnat klipps den i granulat genom plastpelletskäraren. Dessa granulat kan bearbetas till olika plastprodukter genom blåsformning, injektionsformning, kalandering och andra processer.

Kusagwa vifaa vikubwa vya plastiki kuwa chembe ndogo. Hii husaidia katika usindikaji na utunzaji unaofuata na inaboresha ufanisi wa mashine ya pellet.

Mashine ya kuosha ya kuchakata tena ya plastiki

Uchafuzi huondolewa, kuboresha ubora wa kumaliza wa pellets na kupunguza kuvaa kwa vifaa vinavyofuata.

Plastic pellet cutting machine

Wakataji wa pellet ni sehemu muhimu katika tasnia ya kuchakata tena. Kukata vizuri kufanya ukubwa zaidi sare na thabiti ili kukidhi mahitaji ya bidhaa mbalimbali juu ya ukubwa wa pellets, ambayo husaidia kuboresha ubora na uthabiti wa bidhaa ya mwisho.

Je, mashine ya plastiki ya granulating inafanyaje kazi?

Det finns tre huvudsakliga uppvärmningsmetoder för plastpelletiseringsmaskiner: elektromagnetisk uppvärmning, keramisk uppvärmning och induktionsuppvärmning. Du kan välja olika uppvärmningsanordningar beroende på dina specifika behov.

Du kan också konsultera oss; vi rekommenderar rätt maskin för ditt material. Arbetsprincipen för plastgranulatorer inkluderar huvudsakligen följande steg:

- Smältning: avfallplast smälts inuti maskinen genom värmesystemet för att göra den till ett flytande smält tillstånd.

- Extrudering: den smälta plasten passerar genom skruvextruderingssystemet och extruderas till en kontinuerlig granulatform efter verkan av högt tryck och hög temperatur.

- Kylning: snabb kylning och härdning säkerställer formen och kvaliteten på granulerna.

- Skärning: det kontinuerliga granulatmaterialet skärs till den önskade längden av granuler genom skärsystemet i maskinen.

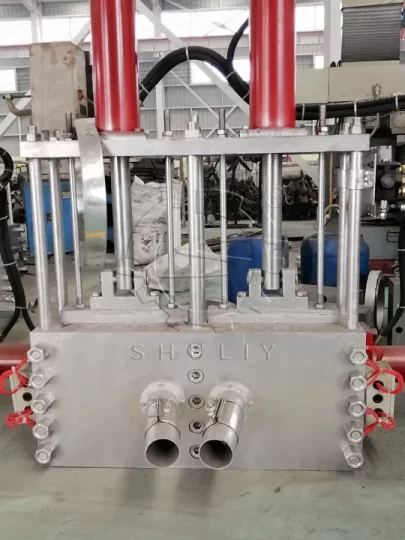

Aina tatu za vichwa vya kufa

Kichwa cha mashine ya plastiki ya pelletizing hudhibiti joto, shinikizo, na kasi ya extrusion, kati ya mambo mengine, na huathiri moja kwa moja ubora na sura ya pellets. Kuna aina tatu, ikiwa ni pamoja na vichwa vya gia za umeme, vichwa vya hydraulic die, na filters za slag moja kwa moja.

taka plastiki extrusion mashine kesi mafanikio

Mashine za plastiki za Shuliy zimesafirishwa kwa mafanikio katika nchi nyingi, kutia ndani Marekani, Ujerumani, Brazili, India, Japan, Australia, Korea Kusini, Afrika Kusini, Uturuki, na Vietnam.

Recently, a customer from South Sudan who is in the recycling business purchased our plastic recycling granulation line. The customer was purchasing a recycling machine for the first time and the installation was very stressful.

Vårt tekniska team stödde kunden under installationsprocessen via videokonferens. Kunden följde instruktionerna och installerade hela maskinen själv. Nedan är feedbacken från användningssidan.

data ya kiufundi ya mashine ya granulating ya pP PE

Mchakato mzima huruhusu urekebishaji sahihi wa umbo, saizi na ubora wa pellets kukidhi mahitaji tofauti ya uzalishaji kwa kudhibiti vigezo kama vile joto, shinikizo, kasi ya kutolea nje na urefu wa kukata.

| Aina | 150 | 180 | 200 |

| Kipenyo cha screw | 150 mm | 180 mm | 200 mm |

| Kasi ya spindle | 40-50/dak | 40-50/dak | 40-50/dak |

| Nguvu kuu ya gari | 37kw | 55kw | 75kw |

| Kipunguzaji (gia ngumu) | 250 | 280 | 315 |

| Uzito | 2T | 2.2T | 2.8T |

| Ukubwa | 3.0*0.7*0.8m | 3.2*0.7*0.8m | 3.5*1*1m |

| Pato | 300KG/H | 350KG/H | 380KG/H |

Kiwanda chetu kina aina mbalimbali za mifano ya mashine za plastiki zinazotengenezwa ili kuchagua, kwa hivyo tafadhali jisikie huru kuwasiliana nasi. Tunaweza kupendekeza mfano unaofaa zaidi kwako.