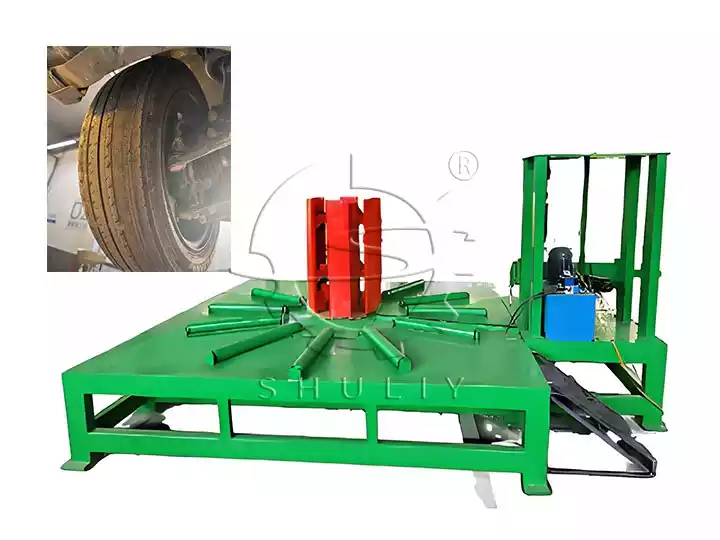

Mashine ya kuondoa matairi ya OTR inaweza kukata kwa ufanisi na kutenganisha kwa usahihi tairi lenye kipenyo cha hadi R63 (>2100mm) na uzito wa tani kadhaa katika vipengele 4-6 sahihi (bead, tread, juu ya tairi, nk.) kwa muda wa dakika chache tu.

Oavsett om du hanterar medelstora däck i intervallet 1400-2000 mm, eller stora gruvdäck i R35-R63-klassen, har vi en banbrytande lösning för dig. Den förbättrar avsevärt bearbetningseffektiviteten och säkerheten, minskar arbets- och driftskostnader, och lägger en solid grund för efterföljande krossning och högvärdig återvinning och återanvändning.

applikationer för stora däckavmonteringsmaskiner

Mashine ya kuondoa matairi ya OTR inatumika sana katika nyanja zifuatazo ili kukidhi mahitaji ya sekta tofauti kwa usindikaji mzuri wa matairi makubwa ya taka:

- Kampuni za recycling za matairi ya zamani: uvunjaji wa awali wa matairi makubwa ya mashine za ujenzi ili kuboresha ufanisi wa kusagwa na kusafishwa kwa hatua inayofuata.

- Viwanda vya uzalishaji wa mpira wa kurejeleza: hutumia tread iliyovunjwa, juu na sehemu nyingine katika mchakato wa kurejeleza na kusafisha mpira.

- Kiwanda cha usindikaji wa chembe za mpira/poda: kama vifaa vya matibabu ya awali kuboresha uzalishaji na ubora wa mchakato wa kugandisha au kusaga matairi.

- Kituo cha kurejeleza rasilimali za mazingira: husaidia katika kupanga na kurejeleza rasilimali, hupunguza gharama za usafirishaji, na kuboresha matumizi ya rasilimali.

- Stationer för service av byggmaskiner och enheter för avveckling: används för att behandla avvecklade OTR-däck, för att uppnå grön demontering och återanvändning.

fördelar med OTR däckavmonteringsmaskin

- Inayoweza kubadilika kwa aina mbalimbali za matairi: inasaidia kushughulikia matairi ya ukubwa wa kati (1400-2000mm kipenyo) na matairi makubwa (R35-R63) ya uhandisi, ikifunika hali mbalimbali za matumizi.

- Salama na haraka: inachukua dakika 5-10 kukamilisha mchakato mzima wa kuondoa.

- System för skärverktyg med hög hållfasthet: använder slitstarka legeringsblad med stark skärkraft och lång livslängd, vilket enkelt hanterar höghållfasthets ståltrådsdäck.

- Udhibiti wa kuendesha kwa maji: hutoa nguvu ya kukata thabiti, operesheni sahihi, na kuhakikisha mchakato wa kuondoa ni salama na mzuri.

- Kiwango cha juu cha automatisering: inasaidia kuanzisha kwa funguo moja na kukata kulingana na mpango, hupunguza uingiliaji wa mikono na kuboresha usalama wa operesheni na ufanisi.

- Uboreshaji wa nafasi inayokaliwa: muundo wa kompakt, eneo dogo linalokaliwa, unaofaa kwa aina zote za maeneo ya kurejeleza na usindikaji.

- Drift med låg energiförbrukning: optimerat hydrauliskt och elektriskt kontrollsystem, energibesparing och miljöskydd, minska driftskostnader.

arbetsprincip för OTR däckavmonteringsmaskin

Mashine ya kubomoa matairi ya OTR inatekeleza uvunjaji mzuri wa matairi makubwa ya ujenzi kupitia kuendesha kwa hidroliki na mfumo wa kukata wenye nguvu kubwa, na mtiririko wake wa kazi wa msingi ni kama ifuatavyo:

- Däcklastning: sätt hela skrotade däck från byggmaskiner på utrustningens arbetsbord på mekanisk eller manuell väg.

- Positionering och klämning: hydraulisk anordning fixerar däcket för att säkerställa stabilitet och att det inte förflyttas under skärprocessen.

- Programinställning: ställ in skärprogrammet enligt däckmodellen för att uppnå exakt nedbrytning av olika delar.

- Kugurudumu kukata: mfumo wa zana za kukata unakata bead, tread, juu na sehemu nyingine za tairi kwa mpangilio, na kuziunganisha katika sehemu nyingi zinazoweza kutumika tena.

- Delar avlastning: efter att skärningen är klar, flytta automatiskt eller manuellt ut de nedbrutna däckdelarna till nästa bearbetningssteg.

parametrar för däckavmonteringsåtervinningsmaskin

| Mfano | OTR däckavmonteringsmaskin | Uppdaterad OTR avlägsnare |

| Arbetsområde | 1400-2000 mm mata | R35-R63 mata (1800-4200 mm) |

| Uwezo | 4-8 pcs/h | 2-6 pcs/h |

| Nyenzo ya blade | legering av volframstål | legering av volframstål |

| Nguvu | 7.5+5.5 KW | 30.5 kw |

| Maskinstorlek | 4.35*3.8*2.4 m | 7.25*3.8*2.98 m |

| Vikt på maskin | 5600 kg | 9900 kg |

Sisi ni kiwanda kitaalamu cha kuchakata matairi, tukijikita katika maendeleo na uzalishaji wa mashine za kubomoa matairi ya OTR.

Wakati huo huo, pia tunatoa vifaa kamili vya usindikaji kwa ajili ya kukata matairi ya taka, kukata(Post inayohusiana: mashine ya kukata matairi ya viwandani), kutenganisha nyuzi, granulation ya goma, n.k., ili kukidhi mahitaji ya kuchakata ya viwango na michakato tofauti.

Vi välkomnar dig att besöka vår fabrik eller konsultera oss för skräddarsydda lösningar och maskinpriser!