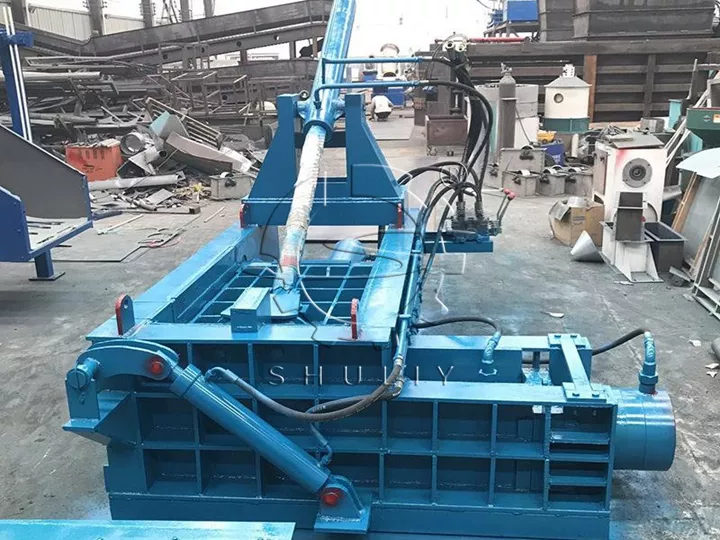

Baler ya metali ya hidroliki ya usawa ina uwezo wa kubana takataka za metali zisizofungwa, magari ya kuondolewa, na metali nyingine za takataka kuwa vizuizi vya compact, uniform vinavyo na wiani wa ≥2200 kg/m³. Hii inapunguza mahitaji ya nafasi ya kuhifadhi na kusaidia usafirishaji na kufaulu kwa kuyeyushwa na recyling.

Mashine ina uwezo wa kuchakata hadi tani 10 kwa saa, inafanya kazi kwa urahisi, ina eneo dogo, na ni rahisi kuendesha. Ni chombo muhimu kwa ajili ya recyling, kuchakata, na matumizi ya metali za takataka, ikiboresha kwa kiasi kikubwa ufanisi wa kuchakata metali za takataka na kupunguza gharama za usafirishaji.

Kwa ufanisi wake wa juu na operesheni ya akili, baler ya metali ya hidroliki imekuwa kipande muhimu cha vifaa kwa vituo vya recyling ya metali za takataka, viwanda vya chuma, na biashara mbalimbali za kuchakata metali ili kuboresha ufanisi wa uzalishaji na kupunguza gharama za usafirishaji.

Aina mbalimbali za maombi kwa ballers za chuma

- Mimea ya kuondoa magari ya takataka: kubana sehemu za metali za takataka kama vile miili ya magari na sehemu za injini.

- Mikakati ya ujenzi: kubana takataka za ujenzi kama vile baraza la chuma na fremu za metali za takataka.

- Mimea ya recyling ya metali: kuchakata aina mbalimbali za metali za takataka, kama vile vifaa vya nyumbani vilivyotupwa, sehemu za takataka, na kontena za takataka.

- Kampuni za utengenezaji: kubana chuma cha takataka, aluminium, shaba, na vifaa vingine vya takataka vinavyopatikana wakati wa mchakato wa utengenezaji.

vipengele vya bales za chuma za kumaliza

- Rahisi kuhifadhi: vizuizi vya metali vilivyobana ni vidogo kwa ukubwa na vinaweza kuwekwa kwa mpangilio mzuri, kuokoa nafasi ya kuhifadhi kwa ufanisi.

- Rahisi kusafirisha: vizuizi vya metali vilivyopangwa na compact vinapunguza gharama za usafirishaji na kuboresha ufanisi wa kupakia na kushughulikia.

- Rahisi kuendelea kuchakata: vizuizi vya metali vinafaa kwa kukandamizwa, kuyeyushwa, na kuchakata kwa kina, kufikia matumizi bora ya rasilimali.

- Ongeza thamani ya recyling: metali zilizopangwa, zenye wiani wa juu zinaweza kuboresha viwango vya recyling kwa ujumla huku zikiongeza thamani ya soko ya metali za takataka.

faida za mashine ya kusawazisha vyuma vya majimaji

- Operesheni laini: mashine imeundwa kwa inertia ya chini na kelele ya chini, kuhakikisha operesheni rahisi na laini, na utendaji wa kuaminika na thabiti wa muda mrefu.

- Eneo dogo: muundo wa muundo wa usawa ni bora kwa viwanda na warsha zenye nafasi ndogo, huku ikirahisisha mpangilio wa eneo la kazi.

- Muktadha mpana wa matumizi: inaweza kubana karibu aina zote za takataka zisizo za ferrous na ferrous, ikiwa ni pamoja na chuma, shaba, aluminium, na zaidi.

- Mspecification nyingi zinapatikana: shinikizo, ukubwa wa hopper, vipimo vya kubana, na sura za kuunda (kwa mfano, mstatili, octagonal, cylindrical) zinaweza kubinafsishwa ili kukidhi mahitaji mbalimbali ya vifaa na watumiaji.

- Uendeshaji rafiki wa mtumiaji: mfumo wa kudhibiti wa akili wa umeme wa kioevu unaruhusu kuanzisha/kuzima kituo kimoja, ulinzi wa kupita kiasi, na alama za makosa.

- Ufanisi wa gharama wa juu: kuunda shinikizo kubwa, kuokoa nishati, hupunguza upotevu wa nishati na gharama za matengenezo huku ikiboresha kwa kiasi kikubwa ufanisi wa uzalishaji.

jinsi mashine ya kuchakata chuma taka inavyofanya kazi?

Katika mchakato mzima, mfumo wa majimaji ni dereva muhimu, kutoa nguvu ya kutosha kukandamiza nyenzo za chuma. Wakati huo huo, muundo wa mitambo, vile, na vipengele vingine pia vina jukumu muhimu katika kuhakikisha kwamba chuma kinaweza kukandamizwa na kupigwa kwa usawa na kwa ufanisi.

- Matning: skrotmetall råmaterial (såsom lösa metallbitar, kasserade delar, gamla hushållsapparater, etc.) läggs in i matningsporten på pressen.

- Positionering och komprimering: materialen skickas in i balningskammaren för positionering, och sedan aktiveras det hydrauliska systemet. Den hydrauliska cylindern trycker presshuvudet eller pressplattan för att starkt komprimera metallmaterialet och trycker snabbt det lösa metallen till en tät block.

- Kufungia na kurekebisha: wakati zimebana hadi ukubwa uliowekwa, vifaa vinafungia kiotomatiki au kwa mikono vizuizi vya chuma, ambavyo vinaweza kurekebishwa kwa waya wa chuma au tepe ya kufunga ili kuzuia vizuizi kutolewa.

- Uondoaji na ukusanyaji: baada ya kukandamiza kukamilika, briquettes za chuma zilizoundwa zinatolewa kupitia mfumo wa uondoaji (mfano, ukanda wa kubebea, mfumo wa kusukuma, n.k.), na kukusanywa kwa kati katika eneo la kuhifadhi au kuhamishwa moja kwa moja.

Parameta za kiufundi za mashine ya kurejeleza chuma taka.

Mashine za kutengenezea chuma zilizotengenezwa katika kiwanda chetu zina sehemu za ubora wa juu na zinakuja na dhamana ya mwaka 1. Ina mfumo maalum wa majimaji na motor. Na pale ambapo hakuna umeme, unaweza kutumia injini ya dizeli kama nguvu. Hapa kuna vigezo vya kina vya kiufundi kwa marejeleo. Tafadhali jisikie huru kuwasiliana nasi, tunakusaidia kuchagua mtindo unaofaa.

| Mfano | Y81-1250A | Y81-1600A |

| Nguvu ya jina (kn) | 1250 | 1600 |

| Chumba cha kubana (mm) | 1200*700*600 | 1600*1000*800 |

| Ukubwa wa kuzuia(mm) | 300*300 | 400*400 |

| Uzito wa kuzuia (kg/m³) | ≥2000 | ≥2000 |

| Uwezo (kg/h) | 1200-1800 | 2000-3500 |

| Muda wa mzunguko mmoja | ≤120 | ≤120 |

| Nguvu (KW) | 15 | 22 |

| Operesheni ya kumwaga bale | Sukuma nje, ushirikiano wa kudhibiti PLC | Sukuma nje, ushirikiano wa kudhibiti PLC |

kesi zilizofanikiwa

Kwa sababu ya ufanisi wake wa hali ya juu, uwezo wa kubinafsishwa, na matengenezo kidogo, mashine zetu za kuchakata chuma zimesafirishwa kwa nchi kadhaa, ikiwa ni pamoja na Kuwait, Urusi, Botswana, Afghanistan, Somalia, Msumbiji, na Uganda.

Imeonyeshwa hapa chini ni tovuti ya kupakia ya usafirishaji wetu uliofanikiwa hadi Ufilipino. Mteja huyu anaendesha kampuni kubwa ya kuchakata chuma chakavu, ambayo imejitolea kwa matibabu madhubuti na utumiaji tena wa chuma chakavu. Tumetengeneza mashine kulingana na mahitaji ya mteja. Mteja huyu alinunua mashine mbili za chuma.

Kiwanda chetu pia kinatoa uteuzi mpana wa vifaa vingine vya kuchakata metali, kama vile mashine za kubana chuma chakavu, ili kukidhi mahitaji mbalimbali ya wateja tofauti. Tumejitolea kukupa suluhisho bora zaidi ili kuongeza ufanisi wako wa kuchakata. Karibu uchunguzi wako, timu yetu ya kitaalamu itakuwa tayari kukupa habari za kina za bidhaa na huduma maalum.