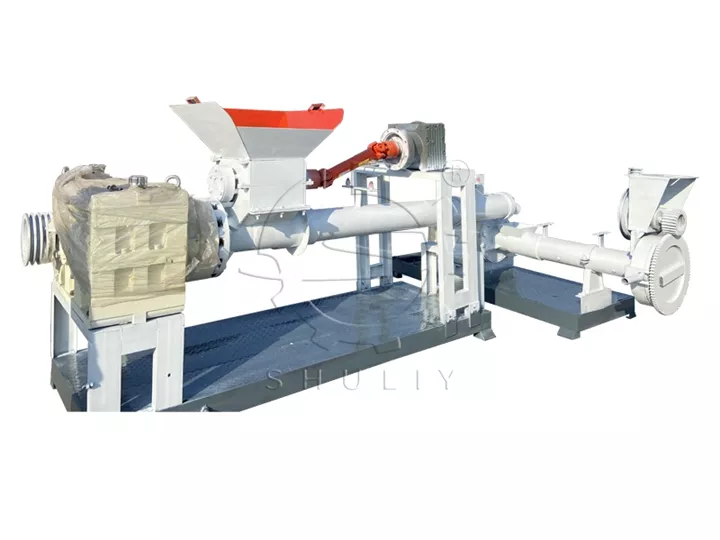

The force feeder is suitable for all kinds of granules, powders, fiberglass, flakes, or co-mingled materials that are difficult to add to the mainframe when the special feeding. This equipment increases productivity and reduces operator burden. Pellet output can be increased by 20-30% compared to manual feeding.

lazimisha maelezo ya mashine ya kulisha

- Mlisho ni pamoja na kipunguza gia kigumu, shimoni la kuendesha gari, na baraza la mawaziri la kudhibiti.

- Mashine inaweza kulisha moja kwa moja filamu kamili ya plastiki ndani ya extruder, chini ya hatua ya shimoni ya gari.

- Wakati nyenzo zimezuiwa, mashine inaweza kugeuka moja kwa moja, ili kufikia faida ya kutozuia nyenzo.

faida za mashine ya kulisha kulazimishwa

- Rahisi kufanya kazi, inaweza kulazimishwa kwa uhuru kushinikiza nyenzo, uzalishaji salama, na kupunguza nguvu ya wafanyikazi.

- Ni kifaa kisaidizi cha lazima kwa filamu, mifuko iliyosokotwa, na granulators nyingine za plastiki zilizosindikwa.

- Mashine inaweza kutumika kwa aina mbalimbali za granulators za plastiki, rahisi kufunga na dismantle.

- Inachukua screw maalum ya kujifunga kwa ajili ya kulisha, na imefungwa vizuri bila kuvuja kwa poda.

- Ina kazi za kusambaza nyenzo zinazoendelea na kusafisha moja kwa moja.

- Nguvu mbele kuendelea kuwasilisha vifaa kucheza faida ya usindikaji line mkutano.

kanuni ya kufanya kazi ya kipakiaji cha kulisha

Katika operesheni, conveyor inadhibitiwa na mfumo wa kuendesha gari ili kuanza operesheni. Malighafi huwekwa kwenye hopa ya kulisha nguvu, ambayo hupigwa na screw ya kifaa cha kulisha na kuendelea kutolewa kwa mashine kuu kwa kiasi sawa kwa kumeza.

Mfumo wa udhibiti hurekebisha kasi ya conveyor kulingana na mahitaji ya uzalishaji ili kudumisha ugavi wa nyenzo mara kwa mara na ufanisi. Ubunifu huu unahakikisha kuwa malighafi hupitishwa kila wakati kwa kasi na kiasi kinachohitajika wakati wa mchakato wa uzalishaji.

Malisho ya kulazimishwa katika mistari ya kuchakata plastiki

Vilisho vya kulazimishwa ni hitaji muhimu katika tasnia ya kuchakata taka za plastiki, ambayo inaonekana hasa katika vipengele vifuatavyo:

- Kuboresha ufanisi wa uzalishaji: Inaweza kutambua usambazaji wa malighafi ya kiotomatiki bila uingiliaji wa mwongozo, ambayo inaboresha ufanisi wa uendeshaji wa laini nzima ya uzalishaji.

- Kuhakikisha ubora wa uzalishaji: Kwa kudhibiti kwa usahihi kasi na kiasi cha usambazaji wa malighafi, mlisho wa nguvu husaidia kuhakikisha uthabiti wa ubora katika mchakato wa uzalishaji.

- Hupunguza Gharama za Kazi: Hupunguza utegemezi wa kazi ya mikono, hupunguza uwezekano wa kufanya kazi kwa mikono, na kupunguza gharama za kazi wakati wa mchakato wa uzalishaji.

- Kuepuka makosa: Mlisho wa nguvu huwasilisha malighafi kwa vifaa vya usindikaji kwa njia thabiti na thabiti, kuepuka kukatizwa kwa uzalishaji na kushuka kwa thamani kwa sababu ya shughuli za mikono.

vigezo vya mashine ya kulisha moja kwa moja

| Driveshaft | SL-150 |

| Nguvu | 5.5KW |

| Kipunguzaji | Kipunguza gia ngumu |

| Baraza la mawaziri la kudhibiti | Ndiyo |

| Driveshaft | Ndiyo |

Kwa maelezo zaidi, tafadhali jisikie huru kuwasiliana nasi na tutakujibu ndani ya saa 24.