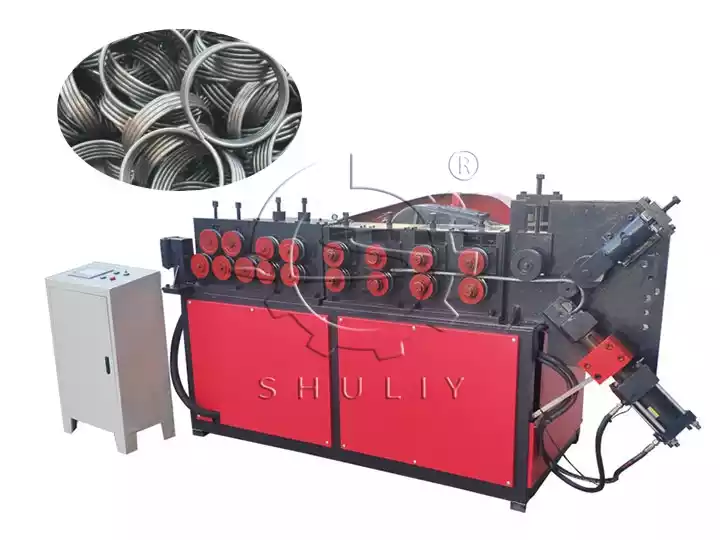

The CNC rebar circle making machine is a high-precision processing equipment designed specifically for manufacturing reinforcing bar loops and spirals in bridge, tunnel, high-speed rail, subway, photovoltaic system, and pile foundation projects.

Its core innovation lies in the dual-drive wheel transmission structure, enabling high-precision single-bend processing of φ3-40mm reinforcing bars with an angular error of ≤1°. Whether processing complex rebar loops, semi-circular arcs, or custom-shaped components, it delivers rapid and precise results, significantly boosting project efficiency.

Suitable not only for construction rebar processing, this equipment also serves mechanical manufacturing, industrial metal forming, and diverse bending applications. Its intelligent human-machine interface ensures intuitive operation even for novices, guaranteeing consistent production accuracy and stability.

advantages of rebar circle making machine

- High efficiency & precision: utilizing dual-drive wheel transmission technology, the rebar circle making machine achieves precise forming in a single bend, reducing repetitive adjustments and boosting efficiency by over 50%.

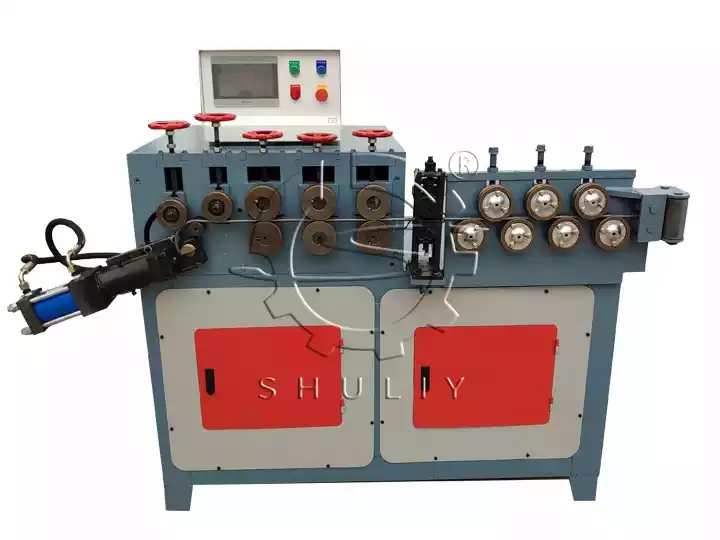

- Intelligent operation: equipped with a user-friendly interface, it offers simple and intuitive operation with angle error controlled within ≤1°.

- Durable and reliable: core components reinforced with anti-wear and impact-resistant technology enable continuous high-intensity operation for 24 hours, extending service life by three times.

- Multi-functional processing: supports bending of rebar, angle steel, flat steel, and round steel to meet construction, machinery, and other processing demands.

- Automatic lubrication system: built-in circulating lubrication automatically protects transmission components, reducing failure rates and extending maintenance intervals to 2000 hours, lowering overall operational costs by 30%.

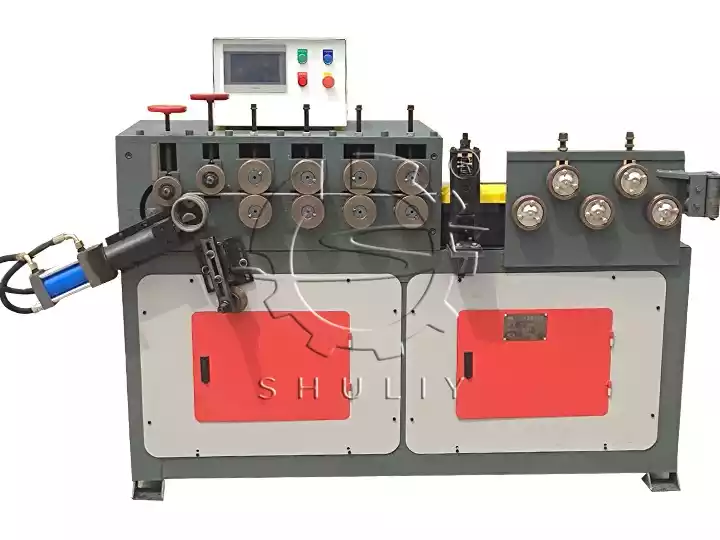

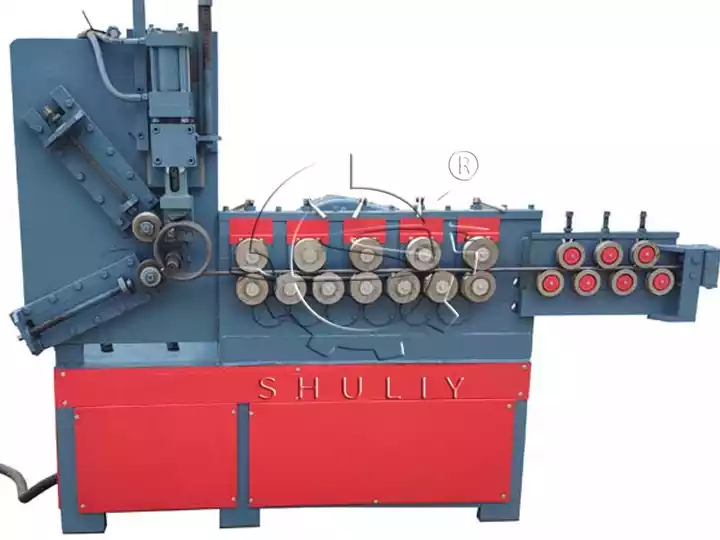

Spring coiling machine Composition structure

The high-speed rebar circle making machine includes an electric motor, hydraulic components (such as an oil pump, hydraulic motor, electronic valve, oil tank, and oil pipes), a pre-adjusting wheel, a straightening gearbox, a rounding assembly, a cutting assembly, and a CNC electrical control program, among other parts.

Applications of steel bar ring making machine

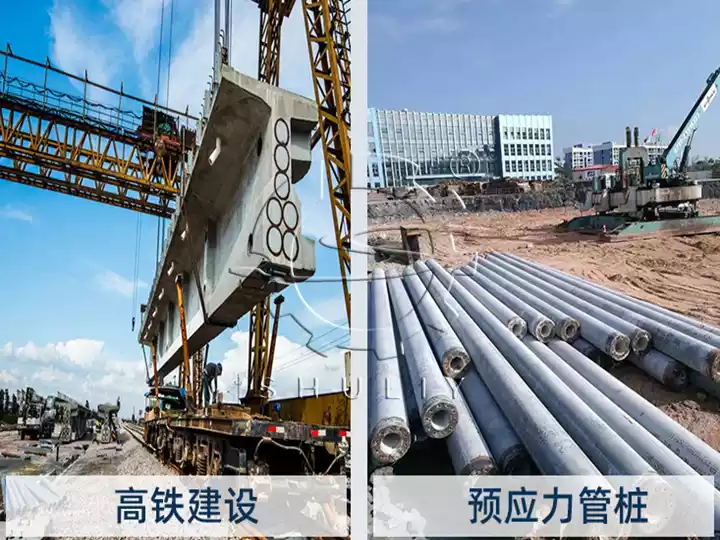

- Railway and bridge engineering: rapid circular reinforcement processing for steel structural components in high-speed railway bridges and piers, enhancing seismic resistance and load-bearing capacity.

- Pile foundation and deep excavation construction: precise control of circular reinforcement diameter optimizes pile compressive and tensile strength, delivering over 40% improved durability in soft soil and deep excavation environments.

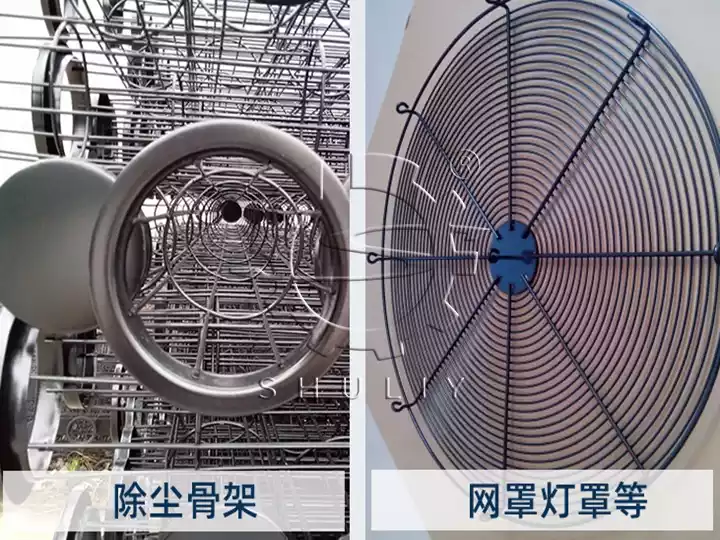

- Industrial metal components: widely used in processing steel structural parts for power plant dust removal equipment and metallurgical machinery. A single machine can produce over 500 pieces daily, ensuring sealing integrity and operational efficiency.

- Architectural decoration and landscape design: capable of processing complex steel components like semicircles, waves, and polygons via preset programs. Ideal for creative applications such as architectural mesh cladding and landscape light covers.

Spiral rebar forming machine Operation principle

- The high-speed rebar circle making machine is initiated by the PLC motherboard, which controls the motor to activate the oil pump. This, in turn, starts the hydraulic component that operates the straightening gearbox, pushing the material forward.

- The material then moves to the rounding assembly to complete the circular formation. Finally, the oil cylinder is engaged to cut the material upward, finishing the operation.

This model allows for batch settings and can automatically process a bundle of steel bars.

CNC automatic rebar rounding machine parameters

Our factory offers a variety of rebar ringing machines. Whether you’re looking to work with fine dusting steel wire or high-speed rail spiral bars, or if you need to mass-produce pre-stressed pipe pile ring bars or create custom-shaped mesh light covers, we have the right rebar circle making machine for you!

| Model | 3-6 | 6-10 | 8-12 | 10-14 | 16-20 | 22-25 |

| Applicable steel bar diameter | 3-6mm | 6-10mm | 8-12mm | 10-14mm | 16-20mm | 22-25mm |

| Total motor power | 4KW | 5.5KW | 7KW | 7KW | 11KW | 15KW |

| Finished steel bar ring diameter | 50-1000mm | 50-800mm | 50-1500mm | 50-1800mm | 50-2200mm | 50-3000mm |

| Travel speed | 16-25m/min | 16-25m/min | 16-25m/min | 16-25m/min | 16-30m/min | 16-30m/min |

| Working error | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

| Overall dimensions | 1.45*0.8*1.2m | 1.55*0.8*1.3m | 1.55*0.8*1.3m | 1.6*0.8*1.35m | 2.1*0.9*1.5m | 2.3*0.9*1.7m |

| Machine weight | 480kg | 560kg | 640kg | 690kg | 1150kg | 1350kg |

Contact us today for a personalized model recommendation!

- → Share your raw material specifications (material / diameter / bending accuracy).

- → Receive a complimentary energy-efficient machine program.

- → Access parameters from real cases and a tailored configuration list.

Our factory manufactures a variety of rebar handling equipment, such as rebar straightening machines and steel bar bending machines. We are fully equipped to meet your project needs! (Feel free to reach out, we respond within 24 hours).