The plastic pelletizing machine, also called a plastic granulator, is an indispensable piece of equipment in the process of waste plastic recycling and reuse. With special screw design and various configurations, this equipment is suitable for regeneration granulation and color mixing granulation of PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PET, PMMA, and other plastic materials.

Both industrial waste and agricultural plastic residues can be efficiently processed and converted into reusable pelletized raw materials, which are widely used in the remanufacturing of plastic products. We offer flexible customization options, low energy consumption operation, and a simplified operation process. The entire set of equipment can be operated by just 1~2 people, helping enterprises save costs and improve efficiency.

uses of plastic pelletizing machine

This machine is ideal for packaging film producers of beverage bottles, commercial bags, garbage bags, agricultural film, food packaging, shrink and stretch film, as well as PP woven bags and jumbo bag producers in the woven industry.

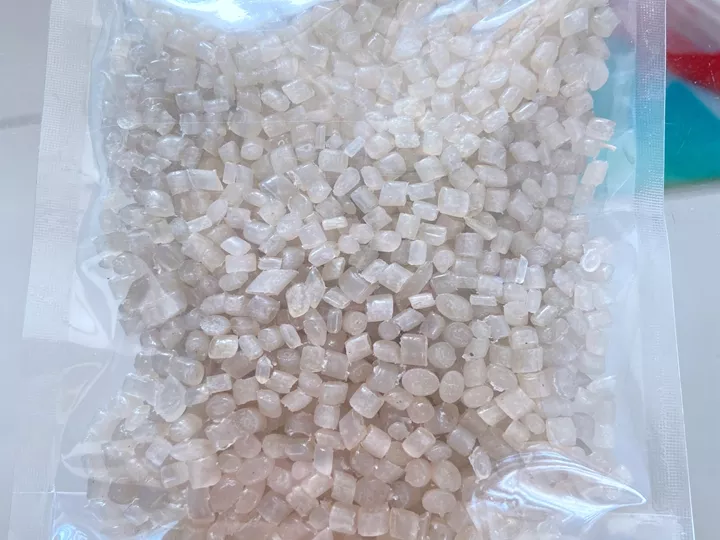

final product from PP PE granule extruder

- The granules are uniform in shape and size, with smooth surface and no burrs.

- The density of granules is moderate, with excellent physical properties, such as high strength, abrasion resistance and corrosion resistance.

- No need for cooling and drying, the cleaned plastic can be granulated directly, simplifying the operation process.

- Adopting electromagnetic heating and automatic temperature control technology, saving energy and avoiding secondary pollution.

- The recycled pellets produced can be 100% used in the manufacture of new products, with high recovery rate and good economic benefits.

plastic granulator machine benefits

- It can handle a wide range of general-purpose and engineering plastics to meet various recycling needs.

- With intermittent heating function, the overall energy consumption is reduced by about 20%, lower operating costs.

- The screw and barrel are treated with special quenching, anti-wear and long life.

- Adopting high torque gearbox design, running smoothly without noise pollution.

- High degree of automation, only 1-2 persons are required to operate, reducing labor investment.

- Provide different screw structure and configuration programs according to material characteristics to ensure the granulation effect.

- The daily processing capacity can reach 20~30 tons, which can meet the mass production of medium and large-scale plastic recycling factories.

plastic pelletizer supporting equipment

The plastic pelletizing machine needs to be used in conjunction with a crusher, a washing machine, and then a plastic granule cutter. Cleaning and drying of waste plastics is the first step in recycling.

Then the clean plastic is melted and plasticized through the screw extruder of the plastic pelletizing machine and extruded into strips. Then after cooling, it is cut into granules through the plastic pellet cutter. These granules can be processed into various plastic products through blow molding, injection molding, calendering, and other processes.

Crushing large plastic materials into small particles. This helps in subsequent processing and handling and improves the efficiency of the pellet machine.

Plastic recycling washing machine

Contaminants are removed, improving the finished quality of the pellets and reducing wear and tear on subsequent equipment.

Plastic pellet cutting machine

Pellet cutters are an essential component in the recycling industry. Fine cutting to make the size more uniform and consistent to meet the needs of different products on the size of pellets, which helps to improve the quality and consistency of the final product.

how does the plastic granulating machine work?

There are three main heating methods for plastic pelletizing machines: electromagnetic heating, ceramic heating, and induction heating. You can choose different heating devices according to your specific needs.

You can also consult us; we recommend the right machine for your material. The working principle of plastic granulators mainly includes the following steps:

- Melting: waste plastic is melted inside the machine through the heating system to make it into a flowing melt state.

- Extrusion: the melted plastic passes through the screw extrusion system and is extruded into a continuous granular form after the action of high pressure and high temperature.

- Cooling: rapid cooling and curing ensure the shape and quality of the granules.

- Cutting: the continuous granular material is cut into the required length of granules through the cutting system in the machine.

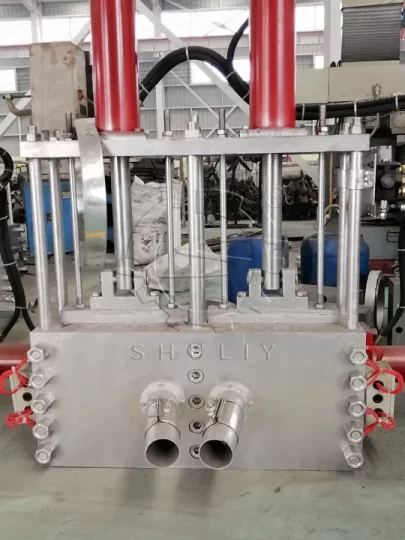

Three types of die heads

The die head of a plastic pelletizing machine controls temperature, pressure, and extrusion speed, among other things, and directly affects the quality and shape of the pellets. There are three types, including electric gear die heads, hydraulic die heads, and automatic slag filters.

waste plastic extrusion machine successful cases

Shuliy’s plastic pelletizing machines have been successfully exported to many countries, including the United States, Germany, Brazil, India, Japan, Australia, South Korea, South Africa, Turkey, and Vietnam.

Recently, a customer from South Sudan who is in the recycling business purchased our plastic recycling granulation line. The customer was purchasing a recycling machine for the first time and the installation was very stressful.

Our technical team supported the customer during the installation process via video conference. The customer followed the instructions and installed the entire machine himself. Below is the feedback from the usage site.

technical data of pP PE granulating machine

The whole process allows precise adjustment of the shape, size, and quality of the pellets to meet different production requirements by controlling parameters such as heating, pressure, extrusion speed, and cutting length.

| Type | 150 | 180 | 200 |

| Screw diameter | 150mm | 180mm | 200mm |

| Spindle speed | 40-50/min | 40-50/min | 40-50/min |

| Main motor power | 37kw | 55kw | 75kw |

| Reducer(hard gear) | 250 | 280 | 315 |

| Weight | 2T | 2.2T | 2.8T |

| Size | 3.0*0.7*0.8m | 3.2*0.7*0.8m | 3.5*1*1m |

| Output | 300KG/H | 350KG/H | 380KG/H |

Our factory has a variety of plastic pelletizing machine models manufactured to choose from, so please feel free to contact us. We can recommend the most suitable model for you.