Recently, our factory successfully delivered a plastic pellet making production line to a customer in Ethiopia. This client primarily works with HDPE and PP plastic raw materials and is dedicated to enhancing the recycling and reuse of plastic waste.

customer background information

Founded in 2018, the customer’s company stands out as one of the prominent local manufacturers specializing in recycled resource processing. The company is dedicated to recycling HDPE (high-density polyethylene) and PP (polypropylene) plastics, aiming to transform waste plastics into industrial raw materials.

This is achieved through effective sorting, crushing, and pelletizing technologies, which help minimize environmental pollution and reduce reliance on imported plastic pellets.

Demand analysis for plastic pellet making production line

- HDPE and PP plastics are known for their high hardness and toughness, which makes traditional crushing equipment prone to wear and less efficient, leading to inadequate production capacity.

- The existing production line suffers from inconsistent crushing granularity and a slow loading speed, failing to meet the demands of the subsequent pelletizing process.

- Customers highlight the importance of low energy consumption, durability, and a low failure rate in equipment to address the challenges posed by an unstable local power supply.

Customized Solution

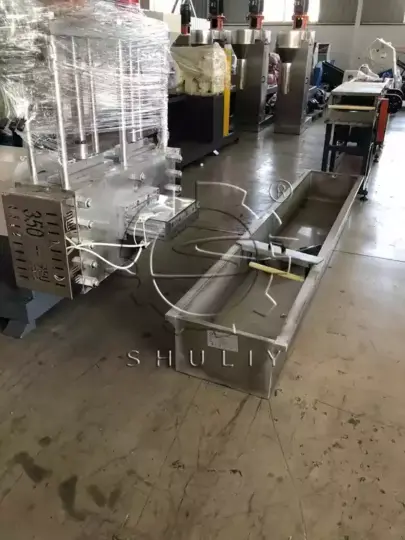

We have tailored a comprehensive set of plastic pellet making production line equipment solutions to meet our customer’s needs, encompassing crushing, conveying, and granulating.

Model 600 hard material crusher

- Features 10 high-quality knives made from 60 silicon 2 manganese steel (6 rotary knives + 4 bottom knives) with a hardness rating of HRC58-62, enhancing impact resistance and extending lifespan by threefold.

- The 16mm sieve design guarantees that the crushed material meets the granulator’s feed size requirements.

- A large 450mm diameter pulley paired with a 22kW motor reduces the speed to 800rpm, optimizing both torque and energy efficiency.

Screw feeder

- The 3000mm extended body is designed to fit seamlessly into the production line layout, while the 4mm thick-walled steel pipe structure is built to withstand high dust environments.

- A dynamically balanced spindle combined with a 6-stage motor ensures a stable material supply of 30kg/min, with a vibration amplitude of less than 0.05mm.

Our single machine can process 4-5 tons daily, which is 40% more efficient than traditional models. Additionally, the overall energy consumption of the entire plastic pellet making production line has been reduced by 25%. If you’re interested in plastic recycling, please don’t hesitate to reach out to us.