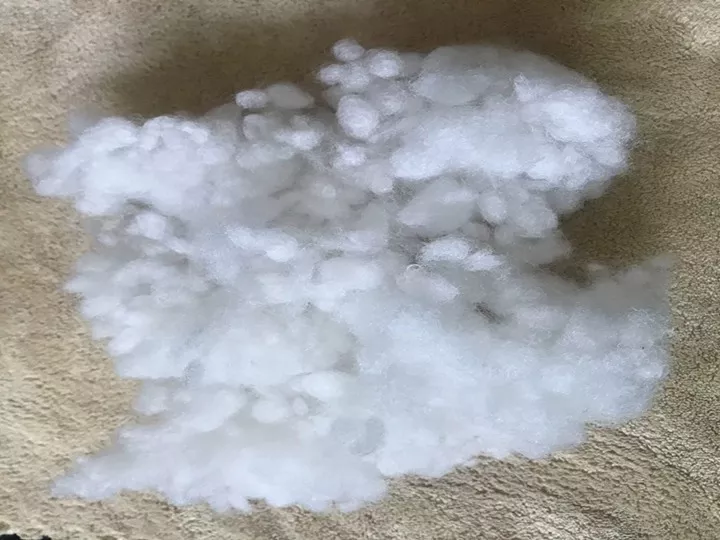

In the field of pillow filling production line, there is a wide variety and abundance of filling materials. Filling materials include a wide range of synthetic materials such as polyester fibers, tufted fibers, and microfibers, as well as natural fibers such as wool and kapok. In addition, these materials can be mixed as needed.

The fiber material is uniform in size, soft, and flexible. Fiber ball diameter size and bulk density can be adjusted according to your production requirements. This process ensures uniform filling volume and product quality consistency, suitable for large-scale, mass production of various types of pillow products in industrial environments. The entire process requires only 1 operator and can process up to 8 pillows per minute.

What are raw materials for making pillows?

Common fillers include feathers, down, polyester fiber, memory foam, latex particles, PP cotton, pearl cotton, microfiber, silk edging, foam particles, feather core, and so on. Different fillings have different elasticity and comfort levels to meet the needs of other users.

finished products you can get

The processed raw material can be utilized to obtain many types of finished products such as dolls, pillows, cushions, neck pillows, and so on by using the pillow filling production line machines.

In addition, the pillow stuffing machine can make down pillows, polyester fiber pillows, memory foam pillows, latex pillows, mixed filling pillows, etc., depending on the filling and pillowcase material chosen.

automatic pillow stuffing line workflow

In a pillow filling production line, the raw material usually needs to be processed by some of the following machines before it enters the pillow charging machine.

Fiber opener machine: raw material processing equipment, this is the initial treatment of the filler equipment. Its main role is to carry out the shrinkage and dispersion of the filler, increase the fluffiness of the filler, so that it is more elastic, to enhance the comfort and support of the pillow.

In addition, the filler can be evenly distributed to ensure that it is evenly filled into the pillow throughout the manufacturing process. This helps maintain the consistency and quality of the pillow. You can gain more detailed information about this machine through the Fiber Opener And Cleaner Waste Textile Recycling Machine.

automatic pillow filling machine working principle

In the pillow manufacturing line, pillow making machine is the most crucial equipment. The working principle is to fill the pre-treated filler evenly and accurately into the pillowcase through mechanical vibration or airflow to realize the production of pillows.

Pillow filling machine usually contains a filling chamber, conveying system, and control system. The filler is transported to the filling chamber through the conveying system and then filled into the pillowcase through vibration or airflow to ensure even distribution, resulting in a comfortable, plump finished pillow.

cotton Pillow sucking machine parameters

To give you a better understanding of our pillow filling lines, we will show you detailed information about the specific parameters of key individual machines. The aim is to help you more comprehensively evaluate and select the most suitable equipment for your production needs.

| Model | SL-ZLD003B-4A | SL-ZLD003B-4B | SL-ZLD005C-2 |

| Capacity | 120-150kg/h | 120-150kg/h | 120-150kg/h |

| Air pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa |

| Voltage | 380v/50hz | 380v/50hz | 380v/50hz |

| Power | 7.25kw | 8.25kw | 1.5kw |

| Weight | 600kg | 850kg | 80kg |

| Dimensions | 4600*1000*1200mm | 5600*1000*2200mm | 1100*900*1200mm |

successful cases of pillow filling production line

Shuliy’s pillow-making machine has now become a hot-selling product and has been successfully sold to nearly forty countries. Its advanced technology and efficient production performance have been well received by customers all over the world.

These countries include but are not limited to: the United States, Canada, Indonesia, Saudi Arabia, Serbia, Nigeria, the United Kingdom, Italy, the Netherlands, Australia, India, South Africa, Kenya, and so on.

pillow making production line advantages

- Increased Efficiency: pillow filler machines can handle large volumes of fiber quickly, significantly boosting the efficiency of the filling process. This allows manufacturers to meet high demands for pillows and cushions while reducing labor costs.

- Consistent Quality: these machines ensure even distribution of fiber throughout the pillow or cushion, resulting in consistently high-quality products. This is crucial for manufacturers aiming to meet specific standards and customer expectations.

- Ergonomic Design: typically designed with ergonomics in mind, these machines allow for easy fiber loading and reduce operator fatigue.

- Versatility: many pillow filler machines can process a variety of fibers, both natural and synthetic, providing producers the flexibility to create different types of pillows and cushions using diverse materials.

- Cost-Effective: investing in a pillow filler machine can be cost-effective by reducing labor expenses, enhancing efficiency, and improving product quality, ultimately paying for itself over time.

Shuliy’s pillow filling production line machines are competitively priced, offering cost-effective equipment with flexible pricing to meet diverse customer needs and budgets. We prioritize customer satisfaction with comprehensive pre-sales consultation and after-sales service, ensuring customers receive the best value for their investment.