The paper pulper machine is an indispensable key piece of equipment in the egg tray production line, its main function is to convert paper recycling products, such as waste paper, cardboard, old newspapers, etc., into pulp after processing and treatment, to be used in the manufacture of egg tray boxes and other paper products production.

Pulp machine in Paper tray production line

Shown below is a working video of the entire paper tray processing process, in which the pulp machine serves as the finished product pre-treatment equipment.

wide applications of waste paper pulper machine

Hydra paper pulper machine has a wide range of applications in pulp manufacturing and related industrial fields, the following are some common application areas:

- Paper industry: The paper pulping machine is the key equipment for manufacturing all kinds of paper and paper products for printing, packaging, writing paper, cardboard, and other paper manufacturing.

- Packaging industry: The pulp produced by paper pulpers is widely used in the manufacture of packaging materials, such as cardboard boxes, paper bags, egg tray boxes, paper cups, and so on.

- Construction and building materials: The pulping paper of machines can be used to produce a variety of fiberboards, such as rigid cardboard, gypsum boards, and fiber cement boards, for use in construction and interior materials.

- Packaging fillers: Paper pulp-making machines convert pulp into filler material that is used to fill boxes or wrap fragile goods, providing protection and cushioning.

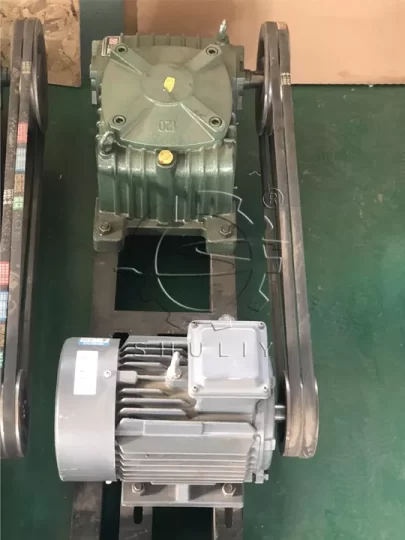

paper pulp making machine’s structure

The main structure of paper pulpers includes the feeding system, crushing system, pulping system, screening system, dewatering system, and control system.

The feeding system is used to introduce waste paper into the machine, the crushing system crushes the waste paper using blades or hammers, the pulping system mixes the crushed waste paper with water to form pulp, the screening system is used to remove impurities, the dewatering system removes the excess water, and finally, the control system monitors and manages the entire process.

These components work together to convert waste paper into high-quality pulp, which provides the raw material for the production of paper and paper-based products.

paper pulping machine main workflow

The working principle of the paper pulper involves a complex process of converting waste paper and pulp materials into pulp. Add 20%-40% of stone powder when making pulp, 60-100 mesh. One cubic meter of waste paper can add 2.5kg of glue. the main steps of which include the following stages:

Soaking

Waste paper is soaked in water, usually with the addition of some chemicals, such as alkaline or acidic substances, to soften the paper and open up the fiber structure. This step helps to separate the cellulose fibers.

Crushing and pulping

After soaking, the waste paper is fed into shredders or pulping equipment. These devices usually include rotating blades, hammer blades, or agitators that are used to break the waste paper into small pieces, which are then dispersed in water through a process of agitation and pulping to form pulp.

Screening and removal of impurities

In this step, the pulp is passed through screening equipment to remove insoluble impurities from it, such as metals, plastics, tapes, etc. This helps to improve the purity of the pulp.

Mediation of consistency

The paper pulper adjusts the consistency of the cellulose pulp to meet the production needs of different types of paper or products. This step usually involves the addition or removal of water.

Dewatering and Discharge

Finally, the pulp needs to pass through a dewatering device, such as a press or centrifuge, to remove excess water and bring the pulp to the desired consistency. Finally, the pulp is discharged to storage tanks or conveyor belts ready for use in paper manufacturing or other related processes.

Technical parameters of egg tray pulper

| Machine name | Model | Power | Unit |

| Hydra pulper | SL1.0 | 7.5kW | 1 set |

| Butterfly valve | DN100 | / | 1 pc |

| Pulp pump | 3 inches | 2.2kW | 1 set |

| Pulp pond beater | 110r/m | 1.5kW | 1 set |

| Waste water pumps | / | 0.75kW | 1 set |

| Pulp conveying pipe | / | / | 1 set |

paper pulping machines factory and shipping diagram

Shuliy can manufacture many different kinds and styles of paper pulpers with high sales volume. For example, they have been exported to the United States, India, and European countries including Germany, France, Sweden, Brazil, and Japan.

These countries and regions have a high demand for pulp machines due to their large paper products industries, and therefore the demand for pulp machines continues to grow to meet a variety of industrial and consumer product needs.

paper mill pulper machine Key Features and Functions

- High-quality products: Pulp produced by pulp machines typically has consistent quality and fiber characteristics, which can be used to make high-quality paper and paper-based products.

- Versatility: The pulp machine can handle different types of waste paper and pulp raw materials, and is suitable for a wide range of product manufacturing, such as paper, cardboard, packaging materials, and so on.

- Automatic control: Modern paper pulper machines are usually equipped with an automated control system, which improves the stability and controllability of the production process.

- Adjustability: The operator can adjust the parameters of the pulp machine to accommodate the production of pulp of different qualities and specifications.

The use of paper pulping machines is vital for environmental protection and resource recovery and helps to reduce environmental pollution by reducing the amount of waste paper going to landfills or incineration.

In egg tray production lines, the role of the pulp machine is to transform sustainable and environmentally friendly raw materials into high-quality paper products, providing key support for sustainable packaging.