The horizontal hydraulic metal baler is capable of compressing loose metal scraps, scrap vehicles, and other scrap metals into compact, uniform blocks with a density of ≥2200 kg/m³. This significantly reduces storage space requirements and facilitates transportation and subsequent smelting and recycling.

The machine has a processing capacity of up to 10 tons per hour, operates smoothly, has a small footprint, and is easy to operate. It is an essential tool for the recycling, processing, and reuse of scrap metal, significantly improving scrap metal processing efficiency and reducing transportation costs.

With its high efficiency and intelligent operation, the hydraulic metal baler has become an essential piece of equipment for scrap metal recycling stations, steel mills, and various metal processing enterprises to improve production efficiency and reduce logistics costs.

Wide range of applications for metal balers

- Scrap car dismantling plants: compressing scrap metal parts such as car bodies and engine parts.

- Construction sites: compressing construction waste such as steel reinforcement bars and scrap metal frames.

- Metal recycling plants: processing various types of scrap metal, such as discarded home appliances, scrap parts, and scrap containers.

- Manufacturing companies: compressing scrap steel, aluminum, copper, and other scrap materials generated during the manufacturing process.

features of finished metal bales

- Easy to store: compressed metal blocks are small in size and can be stacked neatly, effectively saving storage space.

- Easy to transport: neat and compact metal blocks reduce transportation costs and improve loading and handling efficiency.

- Easy to reprocess: metal blocks are suitable for subsequent crushing, smelting, and deep processing, achieving efficient use of resources.

- Increase recycling value: standardized, high-density packaged metals can improve overall recycling rates while enhancing the market value of scrap metal.

hydraulic scrap metal baling machine advantages

- Smooth operation: the machine is designed with low inertia and low noise, ensuring flexible and smooth operation, and reliable and stable long-term performance.

- Compact footprint: the horizontal compact structure design is ideal for factories and workshops with limited space, while also facilitating on-site layout.

- Wide application range: it can compress almost all types of non-ferrous and ferrous metal scrap, including steel, copper, aluminum, and more.

- Multiple specifications available: customizable pressure, hopper size, baling dimensions, and forming shapes (e.g., rectangular, octagonal, cylindrical) to meet diverse material and user requirements.

- User-friendly operation: liquid-electric integrated intelligent control system enables single-station start/stop, overload protection, and fault alarms.

- High cost-effectiveness: high-pressure forming, energy-efficient, reduces energy waste and maintenance costs while significantly improving production efficiency.

how the waste metal recycling baler machine works?

Throughout the process, the hydraulic system is the key driver, providing enough force to compress the metal material. At the same time, the mechanical structure, blades, and other components also play an important role in ensuring that the metal can be compressed and baled evenly and efficiently.

- Feeding: the scrap metal raw materials (such as loose metal pieces, discarded parts, old home appliances, etc.) are put into the feeding port of the baler.

- Positioning and compression: the materials are sent into the baling chamber for positioning, and then the hydraulic system is activated. The hydraulic cylinder pushes the press head or press plate to compress the metal material strongly, and quickly presses the loose metal into a dense block.

- Bundling and fixing: when compressed to the set size, the equipment automatically or manually bundles the metal blocks, which can be fixed with steel wire or baling tape to prevent the blocks from loosening.

- Discharge and collection: after baling is completed, the formed metal briquettes are discharged through the discharging mechanism (e.g., conveyor belt, pushing mechanism, etc.), and centrally collected to the storage area or directly transferred.

Scrap metal recycling machine technical parameters

The metal baling press machines manufactured in our factory have high-quality parts and come with a 1-year warranty. It has a specially customized hydraulic system and motor. And where there is no power supply, you can use a diesel engine as power. Here are the detailed technical parameters for reference. Please feel free to contact us, we help you choose a suitable model.

| Model | Y81-1250A | Y81-1600A |

| Nominal force(kn) | 1250 | 1600 |

| Compression chamber(mm) | 1200*700*600 | 1600*1000*800 |

| Block size(mm) | 300*300 | 400*400 |

| Block density(kg/m³) | ≥2000 | ≥2000 |

| Capacity(kg/h) | 1200-1800 | 2000-3500 |

| Single cycle time(s) | ≤120 | ≤120 |

| Power(KW) | 15 | 22 |

| Bale discharging operation | Push out, PLC control cooperation | Push out, PLC control cooperation |

successful cases

Due to high efficiency, customizability, and low maintenance, our metal baler recycling machines have been shipped to several countries, including Kuwait, Russia, Botswana, Afghanistan, Somalia, Mozambique, and Uganda.

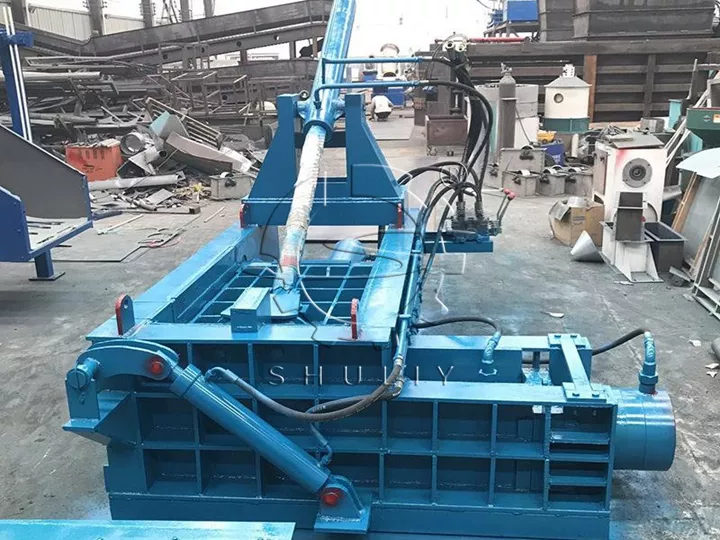

Shown below is the loading site of our successful shipment to the Philippines. This customer operates a large scrap metal recycling company, which is dedicated to the effective treatment and reuse of scrap metal. We designed the machine according to the customer’s needs. This customer purchased two metal balers.

Our factory also offers a wide selection of other metal recycling equipment, such as metal briquetting machines, to meet the diverse needs of different customers. We are committed to providing you with the best solutions to enhance your recycling efficiency. Welcome your active inquiry, our professional team will be ready to provide you with detailed product information and customized service.