The fully automatic tire block cutting machine is a high-efficiency crushing machine designed for volume reduction and resource recovery of waste tires. It directly cuts entire tires into uniformly sized chunks, significantly boosting front-end processing efficiency in tire recycling.

It processes tires with diameters ≤1200mm at a rate of 20–30 tires per hour. Finally, tire blocks of 50-80mm can be obtained. This highly automated and stable equipment serves as a critical pre-processing core in tire recycling, rubber regeneration, and pyrolysis production lines.

tire block cutting machine applications

The fully automatic tire blocker is primarily used in end-of-life tire recycling plants, rubber reprocessing enterprises, solid waste utilization facilities, and as a front-end process in tire pyrolysis projects.

The equipment can directly process whole tires to achieve rapid volume reduction, providing standardized block material for subsequent processes such as grinding, pyrolysis, and fine crushing. This effectively enhances the operational efficiency and continuity of the entire production line.

parameters of tire block cutter machine

| 목 | 사양 |

| Machine Name | Automatic Tire Block Cutting Machine |

| Max Tire Diameter | ≤ 1200 mm |

| 용량 | 20–30 tires / hour |

| Output Size | 50–80 mm |

| 모터 파워 | 40.5 kW |

| 전압 | 380 V |

| Machine Size (L×W×H) | 2000 × 1800 × 1580 mm |

| 무게 | 1.8 T |

| Cable Specification | 35–55 mm |

advantages of hydraulic tire cutting machine

- Highly automated: fully automatic tire feeding and cutting with minimal manual supervision required.

- Consistent processing efficiency: designed for continuous operation to meet the recycling capacity demands of small to medium-sized facilities.

- Uniform cutting: produces uniformly sized output ready for direct transfer to subsequent processes.

- Powerful performance: equipped with high-power motors to process steel-belted tires and reinforced tires.

- Reliable structure: stable center of gravity for sustained high-load operation.

- Enhanced safety: features multiple safeguards and electronic protection systems for worry-free operation.

industrial tire cutter working principle

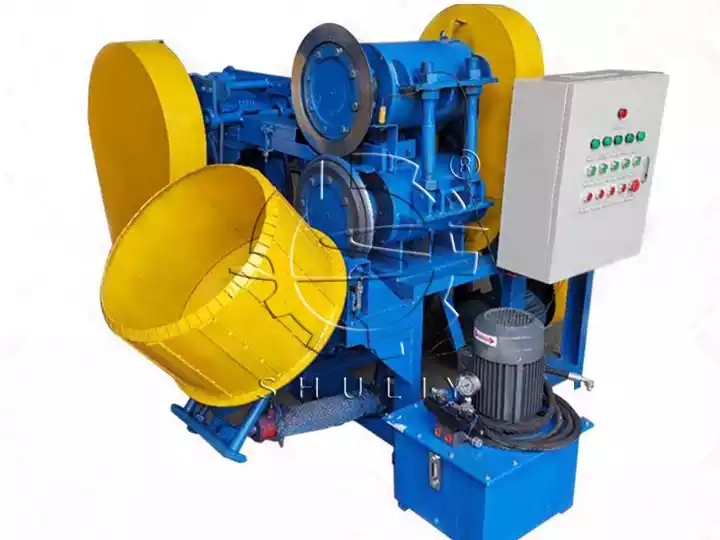

The tire block cutting machine features an integrated mechanical structure, primarily comprising four components: the feeding mechanism, cutting assembly, power transmission system, and electrical control cabinet.

- Feeding mechanism: equipped with a large-diameter funnel-shaped inlet that guides tires into the cutting zone automatically, eliminating the need for manual positioning.

- Cutting assembly: utilizes multiple sets of rotating blades working in coordination to achieve efficient tire shredding through combined shearing and compression actions. The blades are made of wear-resistant alloy material, ensuring a long service life.

- Power transmission system: power is transmitted via a gearbox + chain drive mechanism, ensuring stable operation and low maintenance costs while withstanding prolonged high-load operation.

- Electrical control cabinet: integrates a PLC control system supporting one-button start, emergency stop protection, overload warning, and other functions. The user interface is intuitive, allowing operation without specialized technical personnel.

FAQ

What types of tires can the automatic tire shredder process?

It accommodates various types of scrap tires with diameters <1200mm, including passenger car tires, light truck tires, and certain small steel-belted tires.

Can the output size be adjusted?

The standard output size is 50–80mm. Custom specifications can be achieved by replacing or adjusting the cutting tools.

How many operators are required per machine?

Only 1 operator is needed for feeding and monitoring.

Is equipment maintenance complex?

Maintenance is simple, primarily involving periodic checks of cutting tools, lubrication components, and electrical control systems, with low costs.

Does it support custom voltage or production capacity?

Custom solutions are available for voltage, production capacity, and configuration.

In addition to this equipment, we offer a range of tire recycling solutions, including industrial waste tire shredders, tire strip cutting machines, and other specialized machinery to accommodate varying scales and process requirements. Feel free to contact us anytime to obtain a customized tire recycling equipment configuration tailored to your project’s needs.