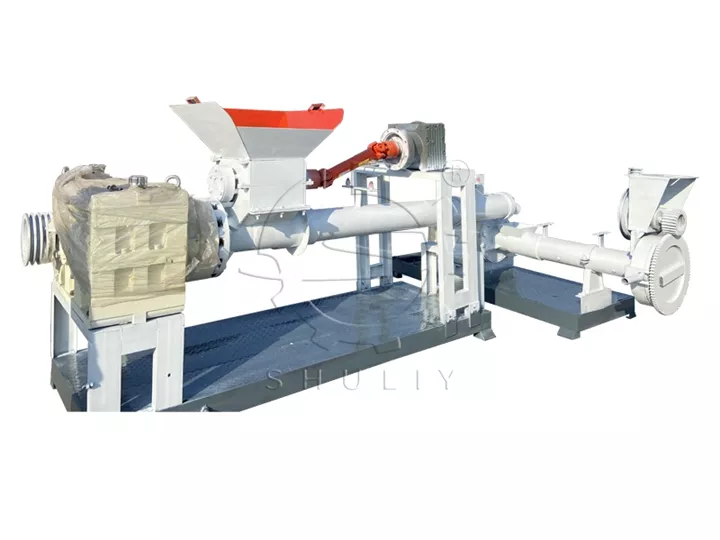

강제 공급 장치는 특수 공급 시 메인프레임에 추가하기 어려운 모든 종류의 과립, 분말, 유리 섬유, 플레이크 또는 혼합 재료에 적합합니다. 이 장비는 생산성을 높이고 작업자 부담을 줄입니다. 수동 공급에 비해 펠릿 생산량을 20-30% 늘릴 수 있습니다.

힘 지류 기계 세부사항

- 피더에는 강화 기어 감속기, 구동축 및 제어 캐비닛이 포함되어 있습니다.

- 기계는 구동축의 작용에 따라 전체 플라스틱 필름을 압출기에 직접 공급할 수 있습니다.

- 재료가 막히면 기계가 자동으로 뒤집혀 재료가 막히지 않는 이점을 얻을 수 있습니다.

강제 공급 기계의 장점

- 작동이 쉽고 독립적으로 재료를 강제로 눌러 생산할 수 있으며 작업자의 노동 강도를 줄일 수 있습니다.

- 필름, 직조 가방 및 기타 재활용 플라스틱 조립기에 없어서는 안될 보조 장비입니다.

- 이 기계는 다양한 유형의 작업에 사용될 수 있습니다. 플라스틱 과립기, 설치 및 해체가 쉽습니다.

- 공급을 위해 특수한 자체 결속 메쉬 나사를 채택하고 분말 누출없이 잘 밀봉됩니다.

- 지속적인 재료 이송 및 자동 청소 기능이 있습니다.

- 조립 라인 처리의 장점을 활용하는 강력한 전방 연속 운반 재료.

강제 공급 로더 작동 원리

작동 중에는 컨베이어가 구동 시스템에 의해 제어되어 작동을 시작합니다. 원료는 힘 공급기 호퍼에 배치되며 공급 장치의 나사에 의해 물려 삼키기 위해 동일한 양으로 주 기계에 지속적으로 공급됩니다.

제어 시스템은 지속적이고 효율적인 자재 공급을 유지하기 위해 생산 요구 사항에 따라 컨베이어 속도를 조정합니다. 이 설계는 생산 공정 중에 원료가 항상 필요한 속도와 양으로 운반되도록 보장합니다.

플라스틱 재활용 라인의 강제 공급 장치

강제 공급 장치는 폐플라스틱 재활용 산업에서 중요한 필수품이며, 이는 주로 다음 측면에 반영됩니다.

- 생산 효율성 향상: 수동 개입 없이 자동화된 원자재 공급을 실현할 수 있어 전체 생산 라인의 운영 효율성이 향상됩니다.

- 생산 품질 보장: 포스 피더는 원료 공급 속도와 양을 정확하게 제어함으로써 생산 공정에서 품질 일관성을 보장하는 데 도움이 됩니다.

- 인건비 절감: 수동 노동에 대한 의존도를 줄이고 수동 작업 가능성을 줄이며 생산 과정에서 인건비를 줄입니다.

- 실수 방지: 포스 피더는 안정적이고 일관된 방식으로 원자재를 처리 장비에 전달하여 수동 작업으로 인한 생산 중단 및 변동을 방지합니다.

자동 공급기 매개변수

| 구동축 | SL-150 |

| 힘 | 5.5KW |

| 감속기 | 강화 기어 감속기 |

| 제어 캐비닛 | 예 |

| 구동축 | 예 |

더 자세한 정보를 원하시면 언제든지 저희에게 연락해 주시면 24시간 이내에 답변을 드리겠습니다.