プラスチックペレット化機械、またはプラスチックグラニュレーターとも呼ばれるこの機械は、廃プラスチックのリサイクルと再利用のプロセスにおいて欠かせない設備です。特別なスクリュー設計とさまざまな構成を備えたこの設備は、PP、PE、PS、ABS、PA、PVC、PC、POM、EVA、LCP、PET、PMMAなどのプラスチック材料の再生グラニュレーションおよびカラー混合グラニュレーションに適しています。

産業廃棄物と農業用プラスチック残留物は、効率的に処理され、再利用可能なペレット状の原材料に変換できます。これらはプラスチック製品の再製造に広く使用されています。私たちは柔軟なカスタマイズオプション、低エネルギー消費の運転、簡素化された操作プロセスを提供しています。全セットの機器は1〜2人で操作でき、企業のコスト削減と効率向上に貢献します。

プラスチックペレット化機の使用

この機械は、飲料ボトル、商業用袋、ゴミ袋、農業用フィルム、食品包装、シュリンクおよびストレッチフィルムなどの包装フィルム製造業者や、織物業界の PP 織袋やジャンボ袋の製造業者に最適です。

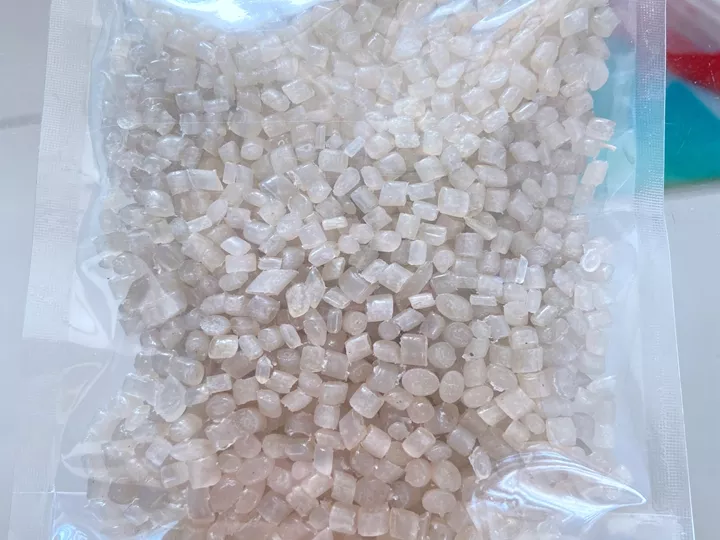

PP PE顆粒押出機からの最終製品

- 粒子は形状とサイズが均一で、表面が滑らかでバリがありません。

- 粒子の密度は中程度で、高強度、耐摩耗性、耐腐食性などの優れた物理特性を持っています。

- 冷却や乾燥の必要がなく、清掃されたプラスチックは直接ペレット化でき、操作プロセスが簡素化されます。

- 電磁加熱と自動温度制御技術を採用し、エネルギーを節約し、二次汚染を回避します。

- 生産されたリサイクルペレットは、新製品の製造に100%使用でき、高い回収率と良好な経済的利益を持っています。

プラスチック造粒機の利点

- 幅広い汎用およびエンジニアリングプラスチックを処理でき、さまざまなリサイクルニーズに対応します。

- 間欠加熱機能により、全体のエネルギー消費が約20%削減され、運転コストが低下します。

- スクリューとバレルは特別な焼入れ処理が施されており、耐摩耗性が高く、長寿命です。

- 高トルクギアボックス設計を採用し、スムーズに運転し、騒音公害がありません。

- 高い自動化の度合いにより、操作には1〜2人しか必要なく、労働投資が削減されます。

- 材料特性に応じた異なるスクリュー構造と構成プログラムを提供し、造粒効果を確保します。

- 日々の処理能力は20〜30トンに達し、中規模および大規模なプラスチックリサイクル工場の大量生産に対応できます。

プラスチックペレタイザー支援装置

プラスチックペレット化機は、クラッシャー、洗浄機、そしてプラスチック粒切断機と併用する必要があります。廃プラスチックの清掃と乾燥はリサイクルの最初のステップです。

次に、清潔なプラスチックは溶かされ、プラスチックペレット製造機のスクリュー押出機を通じてプラスチック化され、ストリップ状に押出されます。その後、冷却された後、プラスチックペレットカッターを通じて粒状にカットされます。これらの粒は、ブロー成形、射出成形、カレンダー加工などのさまざまなプロセスを通じて、さまざまなプラスチック製品に加工することができます。

大きなプラスチック材料を小さな粒子に粉砕します。これは、その後の処理と取り扱いに役立ち、ペレットマシンの効率を向上させます。

汚染物質が除去され、ペレットの仕上がり品質が向上し、その後の装置の磨耗が軽減されます。

プラスチックペレット切断機

ペレットカッターはリサイクル業界にとって不可欠なコンポーネントです。ペレットのサイズに関するさまざまな製品のニーズを満たすために、サイズをより均一かつ一貫させるための微細な切断により、最終製品の品質と一貫性の向上に役立ちます。

プラスチック造粒機はどのように機能しますか?

プラスチックペレット成形機の主な加熱方法は、電磁加熱、セラミック加熱、誘導加熱の3つです。特定のニーズに応じて、異なる加熱装置を選択できます。

私たちに相談することもできます。材料に適した機械をお勧めします。プラスチックグラニュレーターの作業原理は主に以下のステップを含みます。

- 溶融:廃プラスチックは加熱システムを通じて機械内部で溶融され、流動する溶融状態になります。

- 押出成形:溶融したプラスチックがスクリュー押出成形システムを通過し、高圧および高温の作用の後に連続的な顆粒状の形状に押し出されます。

- 冷却:急速冷却と硬化により、粒子の形状と品質が確保されます。

- 切断:連続した粒状材料は、機械内の切断システムを通じて必要な長さの粒子に切断されます。

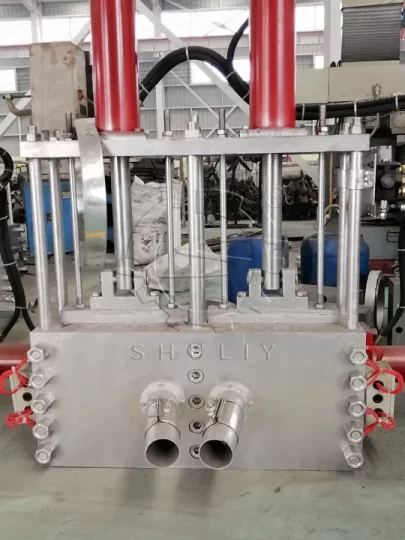

3種類のダイヘッド

プラスチックペレット化機のダイヘッドは、温度、圧力、押出速度などを制御し、ペレットの品質と形状に直接影響を与えます。電動ギヤダイヘッド、油圧ダイヘッド、自動スラグフィルターの3種類があります。

廃プラスチック押出機成功事例

Shuliy のプラスチック造粒機は、米国、ドイツ、ブラジル、インド、日本、オーストラリア、韓国、南アフリカ、トルコ、ベトナムを含む多くの国に輸出されています。

最近、リサイクル事業を行っている南スーダンのお客様が弊社のプラスチックリサイクル造粒ラインを購入されました。お客様は初めてのリサイクル機械の購入であり、設置は非常に大変でした。

私たちの技術チームは、ビデオ会議を通じてインストールプロセス中に顧客をサポートしました。顧客は指示に従い、機械全体を自分でインストールしました。以下は使用現場からのフィードバックです。

pP PE造粒機の技術データ

プロセス全体では、加熱、圧力、押出速度、切断長さなどのパラメーターを制御することで、ペレットの形状、サイズ、品質を正確に調整し、さまざまな生産要件を満たすことができます。

| タイプ | 150 | 180 | 200 |

| ネジ径 | 150mm | 180mm | 200mm |

| 主軸速度 | 40~50/分 | 40~50/分 | 40~50/分 |

| メインモーター出力 | 37kw | 55kw | 75kw |

| 減速機(ハードギヤ) | 250 | 280 | 315 |

| 重さ | 2T | 2.2T | 2.8T |

| サイズ | 3.0*0.7*0.8m | 3.2*0.7*0.8m | 3.5*1*1メートル |

| 出力 | 300KG/H | 350KG/H | 380KG/H |

弊社工場ではプラスチック造粒機を各種取り揃えておりますので、お気軽にお問い合わせください。最適なモデルをご提案させていただきます。