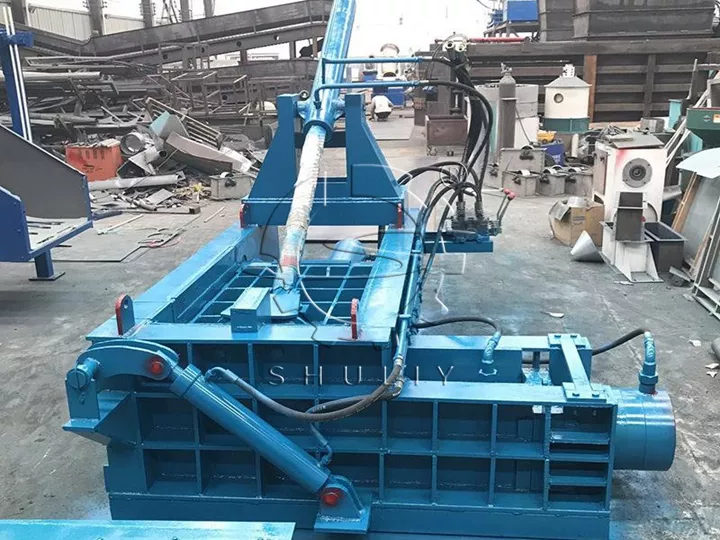

水平油圧金属圧縮梱包機は、緩い金属スクラップ、廃車、その他の金属スクラップを密度≥2200 kg/m³のコンパクトで均一なブロックに圧縮できます。これにより、保管スペースの要件が大幅に削減され、輸送および後続の製錬とリサイクルが容易になります。

この機械は、毎時10トンまでの処理能力を持ち、スムーズに作動し、設置面積が小さく、操作が簡単です。スクラップ金属のリサイクル、加工、再利用に不可欠なツールであり、スクラップ金属の加工効率を大幅に向上させ、輸送コストを削減します。

高効率かつインテリジェントな操作により、油圧金属圧縮梱包機は、生産効率を向上させ、物流コストを削減するための、スクラップ金属リサイクルステーション、製鉄所、およびさまざまな金属加工企業にとって不可欠な機器となっています。

金属ベーラーの幅広い用途

- 廃車解体工場:車体やエンジン部品などの金属スクラップ部品の圧縮。

- 建設現場:鉄筋や金属スクラップフレームなどの建設廃棄物の圧縮。

- 金属リサイクル工場:廃家電、スクラップ部品、スクラップコンテナなどのさまざまな種類の金属スクラップの加工。

- 製造企業:製造プロセスで発生する鋼、アルミニウム、銅、その他のスクラップ材料の圧縮。

完成した金属ベールの特徴

- 保管が容易:圧縮された金属ブロックはサイズが小さく、きちんと積み重ねることができ、保管スペースを効果的に節約します。

- 輸送が容易:きちんとコンパクトな金属ブロックは、輸送コストを削減し、積み込みと取り扱いの効率を向上させます。

- 再加工が容易:金属ブロックは、後続の破砕、製錬、深加工に適しており、リソースの効率的な利用を実現します。

- リサイクル価値の向上:標準化された高密度にパッケージ化された金属は、全体のリサイクル率を向上させると同時に、スクラップ金属の市場価値を高めることができます。

油圧スクラップ金属梱包機の利点

- スムーズな操作:機械は低慣性と低ノイズで設計されており、柔軟でスムーズな操作、信頼性の高い安定した長期的なパフォーマンスを保証します。

- コンパクトな設置面積:水平コンパクト構造設計は、スペースが限られた工場やワークショップに最適であり、現場でのレイアウトも容易にします。

- 幅広い用途:鋼、銅、アルミニウムなど、鉄および非鉄金属スクラップのほぼすべての種類を圧縮できます。

- 複数の仕様が利用可能:圧力、ホッパーサイズ、梱包寸法、および成形形状(例:長方形、八角形、円筒形)をカスタマイズして、多様な材料とユーザーの要件を満たすことができます。

- ユーザーフレンドリーな操作:液体-電気統合インテリジェント制御システムにより、シングルステーションの開始/停止、過負荷保護、および障害アラームが可能になります。

- 高い費用対効果:高圧成形、エネルギー効率が高く、エネルギーの無駄とメンテナンスコストを削減しながら、生産効率を大幅に向上させます。

廃金属リサイクルベーラー機械はどのように機能しますか?

プロセス全体を通じて、油圧システムが主要な駆動力となり、金属材料を圧縮するのに十分な力を提供します。同時に、機械構造、ブレード、その他のコンポーネントも、金属を均一かつ効率的に圧縮して梱包できるようにする上で重要な役割を果たします。

- 供給:スクラップ金属の原材料(例えば、バラバラの金属片、廃棄部品、古い家庭用電化製品など)が圧縮機の供給口に投入されます。

- 位置決めと圧縮:材料は圧縮室に送られ、位置決めが行われた後、油圧システムが作動します。油圧シリンダーがプレスヘッドまたはプレスプレートを押し出し、金属材料を強く圧縮し、バラバラの金属を密なブロックに素早く押し込みます。

- 束ねと固定:設定サイズに圧縮されると、装置は自動的または手動で金属ブロックを束ね、ブロックが緩まないようにスチールワイヤーまたはバンディングテープで固定します。

- 排出と収集:圧縮が完了した後、形成された金属ブリケットは排出機構(例えば、コンベヤーベルト、押し出し機構など)を通じて排出され、中央に収集されて保管エリアに移動されるか、直接転送されます。

スクラップ金属リサイクル機の技術パラメータ

当社の工場で製造された金属梱包プレス機は高品質の部品を使用しており、1年間の保証が付いています。特別にカスタマイズされた油圧システムとモーターを備えています。電源のない場所では、ディーゼルエンジンを動力として使用できます。参考のための詳細な技術パラメータを以下に示します。適切なモデル選びをお手伝いいたしますので、お気軽にお問い合わせください。

| モデル | Y81-1250A | Y81-1600A |

| 公称力(kn) | 1250 | 1600 |

| 圧縮室(mm) | 1200*700*600 | 1600*1000*800 |

| ブロックサイズ(mm) | 300*300 | 400*400 |

| ブロック密度(kg/m3) | ≧2000 | ≧2000 |

| 能力(kg/h) | 1200-1800 | 2000-3500 |

| 単一サイクル時間 | ≤120 | ≤120 |

| 電力(KW) | 15 | 22 |

| ベール排出作業 | 押し出し、PLC制御連携 | 押し出し、PLC制御連携 |

成功事例

由于效率高、可定制性强、维护成本低,我们的金属打包回收机已出口到科威特、俄罗斯、博茨瓦纳、阿富汗、索马里、莫桑比克和乌干达等多个国家。

以下にフィリピンへの出荷に成功した積み込み現場を示します。この顧客は、金属スクラップの効果的な処理と再利用に専念する大規模な金属スクラップ リサイクル会社を経営しています。お客様のニーズに合わせて機械を設計しました。このお客様は 2 台の金属ベーラーを購入されました。

我厂还提供多种其他金属回收设备,例如金属压块机,以满足不同客户的多样化需求。我们致力于为您提供最佳的解决方案,以提高您的回收效率。欢迎您的积极垂询,我们的专业团队将随时为您提供详细的产品信息和定制服务。