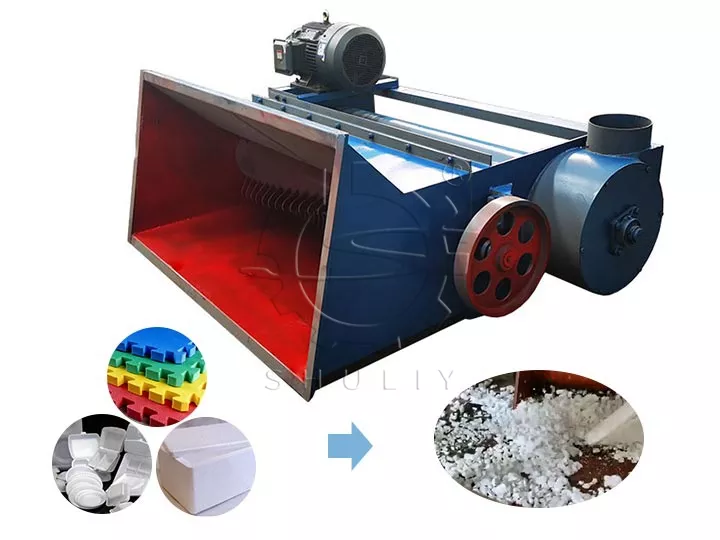

EPS フォームクラッシャー/グラインダーは、EPS フォーム廃棄物を処理するための効果的なソリューションを提供します。泡を扱いやすいサイズまで小さくします。保護パッド、郵送されたパッケージ、その他の壊れやすいガラス/セラミック製品の輸送から発生する廃棄 EPS フォームの処理に最適です。

この発泡リサイクルシュレッダーは、EPSブロックを5mmから50mmのサイズの小さなフレークに粉砕することができます。したがって、その後の保管、輸送、再処理が容易になります。この機械は最大 500kg/h の生産が可能です。

発泡粉砕機の原料

EPS フォームや PE フォームなどは、適切に取り扱わないと環境に重大な汚染を引き起こす可能性があります。 EPS フォームクラッシャーは発泡ポリスチレン用に特別に設計されており、多くの業界でプラスチックフォームの節約とリサイクルに役立ちます。

- EPS: 梱包箱、断熱材。

- PU: シートやクッションの製造に使用されます。

- EPP: 主に自動車部品や梱包材などに使用されます。

- EPE: 断熱材、梱包材。

- PVC: 建材、装飾材等の製造

- その他のフォーム: PPO(ポリフェニレンエーテル)、PIR(ポリイソシアネート)などの各種発泡体

破砕後のEPSフォーム

写真では、廃EPS発泡スチロールがコンパクトな破片に砕かれているのがわかります。粉砕された EPS フォームは、他の製品や他のプラスチックフォームにも使用できます。

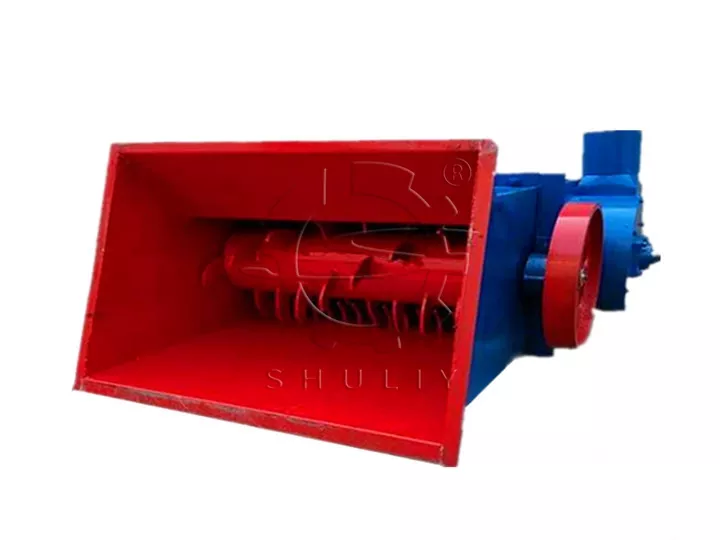

水平発泡シュレッダーの利点

フォームクラッシャーは世界中で人気があり、特に環境保護と資源リサイクルを重視する国や地域で広く使用されています。当社の機械はドイツ、アメリカ、インド、ブラジル、南アフリカ、ナイジェリア、ケニア、メキシコ、インドネシア、サウジアラビアなど多くの国に出荷されています。この機械は以下の重要な利点を提供します。

- 騒音が少ない静音設計を採用しています。

- 大型の給餌ホッパーにより給餌がより便利になります。

- 完成した加工品から発生する発塵を低減します。

- 低エネルギー消費、簡単な操作、低い運用コストとメンテナンスコスト。

- さまざまな形状や密度のフォームの加工に適しており、高い汎用性を備えています。

- 刃が切れなくなったら分解して個別に研ぐことができる着脱式刃を採用。

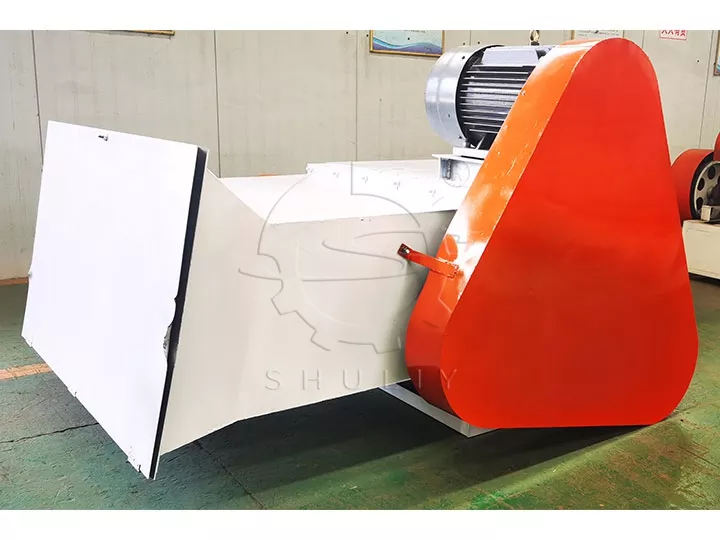

- 横型デザインなので横方向のスペースをとらず、限られた工場や作業場でのレイアウトに便利です。

- 水平設計により、粉砕室内での材料の均一な分布が促進され、粉砕効率が向上し、最終製品の均一性が保証されます。

ポリスチレンクラッシャーマシンの動作原理

- 給餌: 発泡スチロールを発泡粉砕機の供給口に滴下します。

- 切断と粉砕: 機械に入れた後、フォームはブレードまたはナイフで切断され、粉砕されます。これらのブレードは通常、高速で回転し、泡を小さな粒子に切断します。刃は鋼製で丈夫で耐久性に優れています。

- スクリーニング: 切断され粉砕された発泡粒子はスクリーンを通過し、異なるサイズの粒子が分離されます。このステップは、所望の粒径の最終製品を得るのに役立ちます。

- コレクション: ふるいにかけられ、粉砕された発泡粒子は、適切な容器に集められます。これらの粒子は、新しいフォーム製品やその他の用途を製造するためにさらに処理できます。

発泡スチロールシュレッダーの寿命を延ばすにはどうすればよいですか?

- メンテナンスと清掃: 定期的に機器を清掃し、潤滑油を差し、摩耗部品を検査してください。

- 正しい操作:過負荷を避け、均一な供給を維持します。

- 環境条件:乾燥した環境と適切な温度を維持します。

- 高品質のパーツを使用: 純正部品を選択し、劣悪な部品や互換性のない部品の使用を避けてください。

フォームクラッシャーとプラスチッククラッシャーは、どちらもプラスチック材料を粉砕するために使用される装置です。フォーム粉砕機はフォームの加工に特別に使用され、ブレードの設計と加工が特別に最適化されています。

プラスチッククラッシャーはより広範で、硬いプラスチック、柔らかいプラスチックなど、さまざまなプラスチック材料の処理に適しています。この機械については、廃プラスチックPP PEクラッシャーリサイクル機から詳細な情報を得ることができます。

EPSフォーム破砕機のパラメータ

| タイプ | 全体のサイズ(mm) | 供給口サイズ(mm) | 電力 (KW) | 容量(KG/H) |

| 800 | 1250*1290*660 | 800*600 | 5.5 | 250-300 |

| 1000 | 1250*1530*660 | 1000*600 | 5.5 | 300-350 |

| 1200 | 1300*1730*700 | 1200*600 | 7.5 | 400-450 |

| 1500 | 1600*2200*800 | 1500*800 | 11 | 450-500 |

泡粉砕機の処理能力およびその他のパラメータは、特定のモデルによって異なります。購入する前に、実際の需要に応じて適切なモデルを選択する必要があります。最適なモデルをご提案させていただきますので、詳しくはお気軽にお問い合わせください。

さらに、当社の工場では、スタイロフォーム熱溶解機や冷間圧縮機など、EPSフォームのリサイクルのための他の機械も製造しています。ここで適切な機器を見つけることができ、あなたとの協力を楽しみにしています。