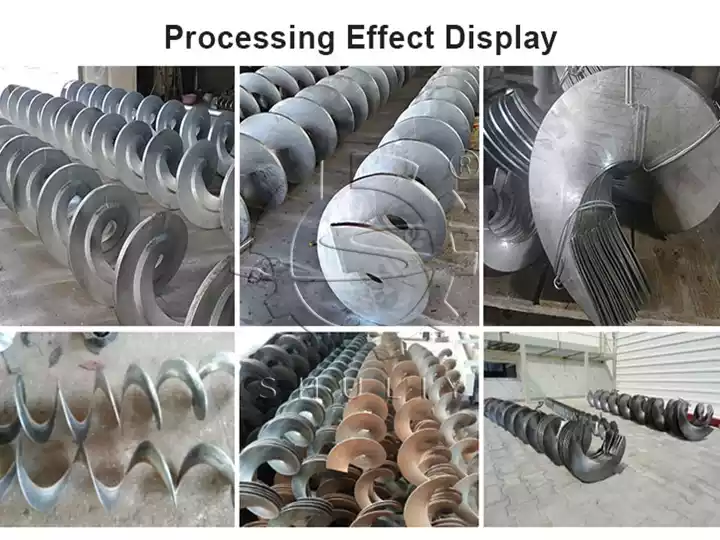

Mesin pembentuk bilah spiral adalah peralatan yang sangat efisien yang dirancang khusus untuk produksi bilah konveyor spiral dan bilah bor spiral. Ini banyak digunakan di industri seperti pertanian, perlindungan lingkungan, pertambangan, bahan kimia, dan farmasi.

Peralatan ini dapat membentuk bilah spiral dengan spesifikasi dan ukuran yang berbeda secara presisi untuk memenuhi kebutuhan pelanggan, memungkinkan pengangkutan dan pencampuran material yang efisien dan andal. Dengan akurasi pembentukan yang luar biasa dan kinerja yang stabil, mesin pembentuk bilah spiral telah menjadi alat penting untuk solusi pengangkutan spiral yang disesuaikan di berbagai industri.

Aplikasi mesin pembentuk bilah spiral

- Mesin pertanian: memproduksi bilah spiral untuk mengangkut material seperti biji-bijian dan pakan.

- Mesin perlindungan lingkungan: memproduksi bilah spiral untuk pembuangan limbah dan pengangkutan lumpur.

- Peralatan pertambangan: memproduksi bilah pengangkut efisiensi tinggi yang cocok untuk material seperti bijih dan batu bara.

- Industri kimia: memproduksi bilah spiral yang disesuaikan untuk penanganan material kimia.

- Industri farmasi: memenuhi kebutuhan pencampuran dan pengangkutan material dalam produksi farmasi.

prinsip kerja mesin penggulung penerbangan sekrup

Mesin pembentuk bilah spiral mendorong bahan mentah ke dalam cetakan khusus melalui sistem mekanis atau hidrolik. Di bawah bimbingan cetakan dan penerapan tekanan, material mengalami deformasi plastis dan secara bertahap membentuk bilah spiral.

Proses ini memastikan bahwa bilah memiliki akurasi dimensi dan keseragaman struktural, memenuhi persyaratan produksi untuk berbagai diameter, jarak bilah, dan spesifikasi, serta menyediakan produk jadi berkualitas tinggi yang cocok untuk berbagai aplikasi pengangkutan dan pencampuran industri.

Dua jenis mesin bilah konveyor sekrup

Untuk memenuhi kebutuhan berbagai industri dan volume produksi, kami menawarkan dua model mesin pembentuk bilah spiral: mesin pembentuk bilah spiral satu keping dan mesin pembentuk spiral kontinu.

Setiap model memiliki fitur uniknya sendiri dan cocok untuk skenario produksi bilah yang disesuaikan dan bervolume tinggi. Bagian berikutnya akan memperkenalkan fitur dan aplikasi dari kedua model ini untuk membantu Anda memilih peralatan produksi yang paling sesuai berdasarkan kebutuhan aktual Anda.

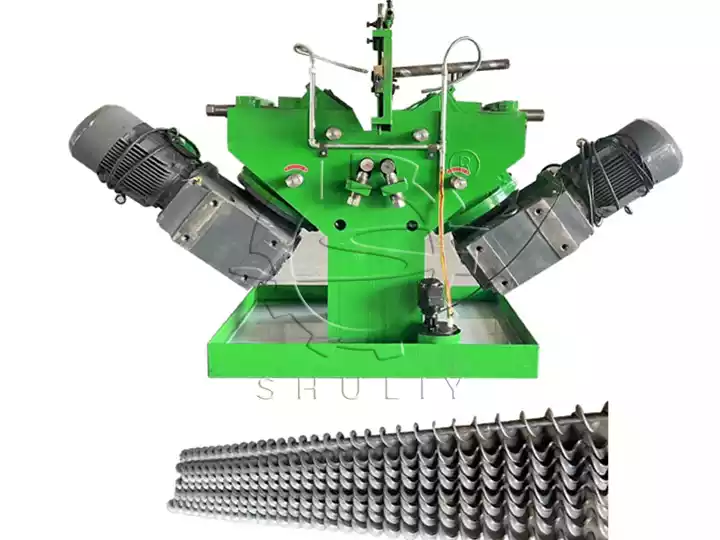

mesin pembentuk penerbangan spiral satu keping

Mesin pembentuk bilah spiral satu keping dirancang khusus untuk membentuk pelat logam padat secara dingin menjadi bilah spiral yang kontinu dan tanpa las. Ini banyak digunakan dalam aplikasi seperti konveyor spiral, peralatan pengeboran, mesin pertanian, pengolahan pakan, semen, dan penyimpanan biji-bijian.

Peralatan ini mendukung pembentukan bilah dengan diameter luar 400–1400 mm, diameter lubang dalam ≥12 mm atau ≥20 mm, dan pitch 50–800 mm, memenuhi berbagai persyaratan spesifikasi, dan sangat cocok untuk produksi yang disesuaikan dari ukuran menengah hingga besar.

Kinerja Inti

- Sebuah lembaran logam dapat digulung dingin menjadi bilah spiral pitch tetap atau pitch variabel dalam satu proses, menghilangkan kebutuhan untuk pengelasan. Ini menghasilkan kekuatan yang lebih tinggi dan permukaan yang lebih halus pada produk jadi.

- Mendukung baja karbon (Q235, Q345), stainless steel (304, 316L), dan pelat tahan aus berkekuatan tinggi (misalnya, NM360/400/500, Hardox 450/500) dengan ketebalan berkisar 2–12 mm.

- Dengan mengubah cetakan, material dengan kekerasan berbeda (misalnya, baja karbon 30 mm dan pelat tahan aus 8 mm) dapat mencapai diameter dalam, diameter luar, dan pitch yang sama.

Keuntungan Peralatan

- Bilah spiral yang dihasilkan memiliki kekuatan keseluruhan yang lebih tinggi, ketahanan aus yang superior, dan kinerja keseimbangan dinamis yang lebih baik dibandingkan dengan bilah las segmen tradisional.

- Dibandingkan dengan proses pemotongan sektor tradisional + pengelasan, konsumsi material dapat dikurangi sebesar 8–12%.

- Setiap bilah hanya membutuhkan waktu 1–3 menit untuk dibentuk (tergantung pada ukuran), secara signifikan meningkatkan kapasitas produksi.

- Mudah dioperasikan; operator baru dapat menguasai proses dalam 30 menit.

parameter mesin

| Model | 250–12 | 350–16 | 350–25 | 500–16 | 800–25 |

| Diameter pemrosesan (mm) | 200×2 + poros dalam Ø | 300×2 + poros dalam Ø | 300×2 + poros dalam Ø | 400×2 + poros dalam Ø | 700×2 + poros dalam Ø |

| Pitch pemrosesan (mm) | 100–500 | 100–700 | 100–700 | 100–1000 | 200–1500 |

| Ketebalan lembar maksimum (mm) | Baja karbon 12 Baja tahan karat 10 Pelat tahan aus 6 | Baja karbon 16 Baja tahan karat 12 Pelat tahan aus 8 | Baja karbon 25 Baja tahan karat 20 Pelat tahan aus 16 | Baja karbon 16 Baja tahan karat 12 Pelat tahan aus 8 | Baja karbon 25 Baja tahan karat 16 Pelat tahan aus 16 |

| Tinggi cetakan (mm) | 260 | 355 | 355 | 500 | 850 |

| Daya (kW) | 4 | 5.5 | 7.5 | 7.5 | 11 |

| Sumber daya | 380V, 50Hz | 380V, 50Hz | 380V, 50Hz | 380V, 50Hz | 380V, 50Hz |

| Ukuran penampilan (mm) | 2200×500×1200 | 2700×550×1200 | 2700×550×1200 | 2900×650×1350 | 2900×650×1350 |

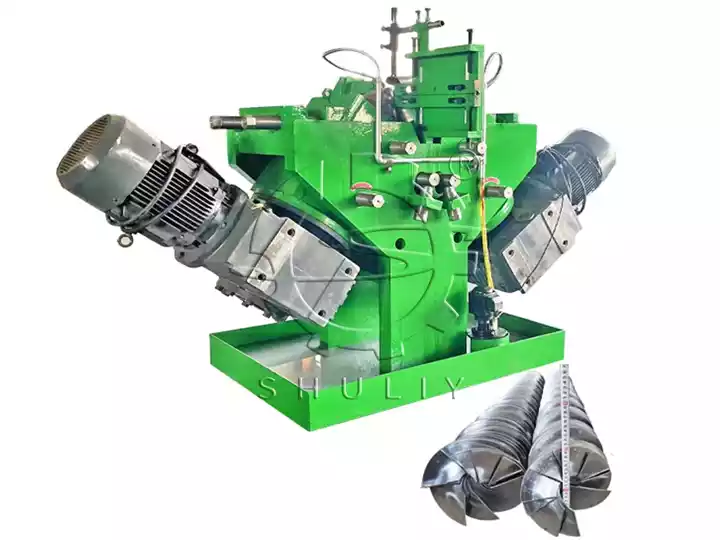

mesin pengelasan bilah spiral kontinu

Mesin pembentuk bilah spiral kontinu dapat memproses strip baja panjang secara terus menerus menjadi bilah spiral dengan panjang berapa pun tanpa las.

Ini sangat cocok untuk skenario produksi volume tinggi dan banyak digunakan dalam spiral pengangkut pakan, spiral pengolahan makanan, perangkat pengangkut kecil, peralatan ekstrusi farmasi, penggerak filamen pencetakan 3D, dan pompa metering presisi.

Mesin pembentuk bilah spiral ini mendukung pemrosesan material strip baja dengan ketebalan 2–6 mm dan lebar 15–150 mm (termasuk baja karbon, baja tahan karat, baja pegas, aluminium, kuningan, dll.).

Diameter luar bilah spiral yang terbentuk dapat mencapai sekitar 20–300 mm, dengan diameter dalam ≥8 mm. Rentang pitch dapat disesuaikan secara bebas selama operasi untuk memenuhi berbagai persyaratan spesifikasi.

Fitur mesin

- Cocok untuk strip baja dari berbagai material dan ukuran, dengan dimensi pembentukan mulai dari diameter kecil hingga sedang.

- Dilengkapi dengan sistem PLC + HMI, mendukung penyimpanan resep dan pemanggilan parameter, dengan kesalahan pitch kurang dari 1 mm/m.

- Terintegrasi uncoiling → pelurusan → pemberian servo → pembentukan → pemotongan terbang gergaji dingin, output kontinu tanpa gangguan.

- Penggantian poros inti hanya memerlukan waktu 5–10 menit, secara signifikan mengurangi waktu pergantian.

Sorotan Peralatan

- Meningkatkan umur lelah bilah spiral, permukaan lebih halus, mudah dibersihkan, cocok untuk industri makanan dan farmasi.

- Bilah kecil dapat mencapai kecepatan hingga 30 meter per menit, secara signifikan meningkatkan efisiensi produksi.

- Proses pembentukan kontinu menghasilkan kehilangan material yang sangat rendah, dengan tingkat scrap kurang dari 1%.

- Peralatan ini hanya memerlukan ruang lantai sekitar 2 meter × 1 meter, sehingga cocok untuk digunakan dalam lini produksi modular atau bengkel kecil.

data teknis

| Model | LX120-5 | LX40-5 | LX150-5 |

| Material lembar yang dapat diterapkan | SPHC | SPHC, SPHD, SPHE | SPHC, SPCC |

| Voltase | 380V | 380V | 380V |

| Daya motor utama | 15kW×2 | 15kW×2 | 15kW×2 |

| Total daya | 26kW | 15kW | — |

| Lebar strip sisi tunggal | 20–120mm | 15–40mm | 20–150mm |

| Ketebalan lembar | 2–6mm | 2–4mm | 2–6mm |

| Toleransi lubang dalam bilah yang digulung | ≤±3mm | ≤±3mm | ≤±3mm |

| Diameter luar bilah yang digulung | 60–750mm | 40–300mm | 80–800mm |

| Toleransi diameter luar | ≤±5mm | ≤±5mm | ≤±5mm |

| Pitch bilah yang digulung | 50–800mm | 50–800mm | 50–800mm |

| Toleransi pitch | ±5mm | ±5mm | ±5mm |

| Mode kerja | Dua rol beroperasi secara bersamaan | Dua rol beroperasi secara bersamaan | Dua rol beroperasi secara bersamaan |

| Metode penyesuaian | Penyesuaian sekrup mekanis | Penyesuaian sekrup mekanis | Penyesuaian sekrup mekanis |

| Komposisi peralatan | • Mesin utama bilah spiral • Meja pemuatan mekanis • Pemotong hidrolik • Kabinet distribusi daya | • Mesin utama bilah spiral • Meja pemuatan mekanis • Pemotong hidrolik (dengan platform 2m) • Kabinet distribusi daya | • Mesin utama bilah spiral • Meja pemuatan mekanis • Pemotong hidrolik (dengan platform 2m) • Kabinet distribusi daya |

| Total berat | 4t | 4t | 5.5t |

Kami adalah pabrik yang mengkhususkan diri dalam penelitian, pengembangan, dan pembuatan mesin pembentuk bilah spiral, berkomitmen untuk menyediakan solusi pembentukan logam yang efisien dan stabil untuk berbagai industri. Kami juga memproduksi berbagai macam peralatan pengolahan dan perlakuan logam. Kami menyambut pelanggan untuk mengunjungi pabrik kami, terlibat dalam pertukaran teknis, atau menanyakan tentang kerjasama!