The vertical hydraulic cardboard baler is an industrial tool that compresses loose materials such as cartons, plastics, and metal scraps to 1/10 of their original volume through ultra-high pressure of 80-200 tons.

It not only solves the industry pain points such as high cost of traditional bulk transportation and waste of storage space, but also realizes “one machine with multiple functions”. From regular bundling of waste cardboard to high-density briquetting of cans, from recycling of textile scraps to pre-treatment of industrial waste metals, more than 20 material scenarios can be adapted by simply adjusting the pressure parameters.

Brief Introduction of Hydraulic Cardboard Baler

A hydraulic baler usually consists of a compression chamber, hydraulic cylinders, a control system, and a conveyor system. The operator places the material to be processed into the compression chamber and the hydraulic cylinder is activated by the control system to apply pressure to compress the material into a parcel.

Once compression is complete, the parcels are typically conveyed or discharged through the conveying system for further storage or transportation. Hydraulic balers are divided into two types: Vertical hydraulic cardboard balers and Horizontal hydraulic carton balers.

Wide Application Of Hydraulic balers

Hydraulic cardboard balers are widely used in the waste recycling industry to pack waste paper, waste plastics, waste metals, waste fibers, and other materials into compact blocks for subsequent transportation and recycling.

- Pulp and paper industry: they are used for baling waste paper and pulp materials for transportation to pulp mills or paper production plants for manufacturing recycled pulp and paper products.

- Metal recycling: used to compress scrap metal, such as scrap steel, scrap aluminum, scrap copper, etc., to be transported to the metal recycling plant for reprocessing and smelting.

- Plastic recycling: hydraulic cardboard balers can be used for baling waste plastic containers, bottles, and waste plastic products for transportation to plastic recycling plants for recycling.

- Fiber material handling: in the fiber products industry, they are used to compress natural or synthetic fibers such as cotton, flax, wool, etc., so that they can be used in the manufacture of textiles and insulation materials.

Packing finished product display

The finished product of a hydraulic cardboard baler is a parcel of material that has been baled and compressed, usually in the form of a square or rectangular block structure.

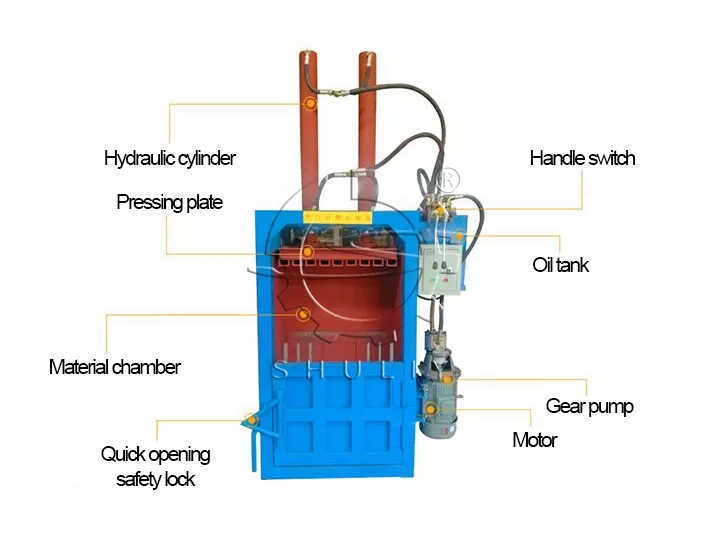

Carton baling machine main structure

The main structure of a hydraulic cardboard baler usually includes the following parts:

- Compression chamber: it is the core component of a hydraulic baler and is used to contain and compress the waste or recyclable material to be processed. The compression chamber is usually of sturdy construction to withstand high pressure.

- Hydraulic cylinder: it is responsible for applying pressure to compress the waste into blocks. Hydraulic cylinders are usually made of steel and have high-pressure fluid input and output ports that are fed with hydraulic fluid to achieve the compression operation.

- Hydraulic system: it consists of components such as hydraulic pumps, tanks, hydraulic fluid lines, and control valves used to provide high-pressure fluid to drive the hydraulic cylinders. This system ensures efficient working of the machine and compression operation.

- Structural frame: the entire hydraulic baler is usually mounted on a sturdy structural frame to provide stability and support.

The structure and components of a carton hydraulic baler may vary from manufacturer to manufacturer and model to meet the needs of different applications.

These machines are often customized based on the type of material being handled, compression capacity, level of automation, and other factors.

Overall, hydraulic cardboard balers are constructed to efficiently compress waste and recyclable materials into blocks for storage, transportation, and recycling.

Hydraulic baling machine Workflow

The working principle of a hydraulic carton baler can vary depending on the model of the machine and the material being processed, but the steps outlined above are a general overview of its basic operating principles. The design and performance of these machines will vary depending on the needs of the application.

Feeding

Waste or recyclable material to be disposed of enters the feeding area of the baler via a conveyor belt, manual loading, or other means.

Compression chamber loading

The operator places the raw material into the compression chamber of the hydraulic cardboard baler. This compression chamber is usually an open container that can hold a certain amount of waste.

Hydraulic system works

The key part of the hydraulic baler is the hydraulic system, which consists of hydraulic cylinders, pumps, tanks, and control valves. The hydraulic system provides high-pressure hydraulic oil and applies pressure through the hydraulic cylinder to compress the raw material into compact blocks.

Compression process

The hydraulic cylinders will move downward and apply constant pressure on the waste to compress it into blocks. This process can continue for some time depending on the material being processed and the design of the equipment.

Finished Product Discharge

Once compression is complete, the finished product is usually discharged from the discharge port of the baler. These finished packages are usually square or rectangular blocks with a compact structure.

Advantages of Hydraulic baler machine

- They can compact waste and recyclable materials into neat blocks, which not only saves space but also cuts down on storage and transportation costs.

- These machines are all about efficiency too. Hydraulic cardboard balers can run automatically, making waste disposal quicker and helping to lower labor expenses.

- One of the best things about hydraulic balers is their versatility. They can handle a wide range of materials, from waste paper and plastics to metals, wood, fabrics, and beyond.

- Plus, they’re customizable! You can adjust the size, capacity, and features of hydraulic balers to fit the specific needs of different applications.

cardboard baling machine main Technical data

| Model | SL40QT | SL60QT | SL80QT |

| Hydraulic power | 40Ton | 60Ton | 80Ton |

| Packaging size(L*W*H) | 720*720*300-1600mm | 850*750*300-1800mm | 1100*800*300-2000mm |

| Feed opening size(L*H) | 1000*720mm | 1200*750mm | 1500*800mm) |

| Bale density | 300Kg/m³ | 350Kg/m³ | 400Kg/m³ |

| Bale line | 4Line | 4Line | 4Line |

| Capability | 1-3T/hour | 2-4T/hour | 4-7T/hour |

| Bale wire | 12#*4 PCS | 12#*4 PCS | 12#*4 PCS |

| Power | 18-22KW/24-30HP | 22-30KW/30-40HP | 30-45KW/40-60HP |

| Machine weight | About 8Ton | About 10Ton | About 13Ton |

For other raw materials to be processed, we have waste clothing balers and machines for packing metal available. If you want to get more types and models of technical parameters, please feel free to contact us.