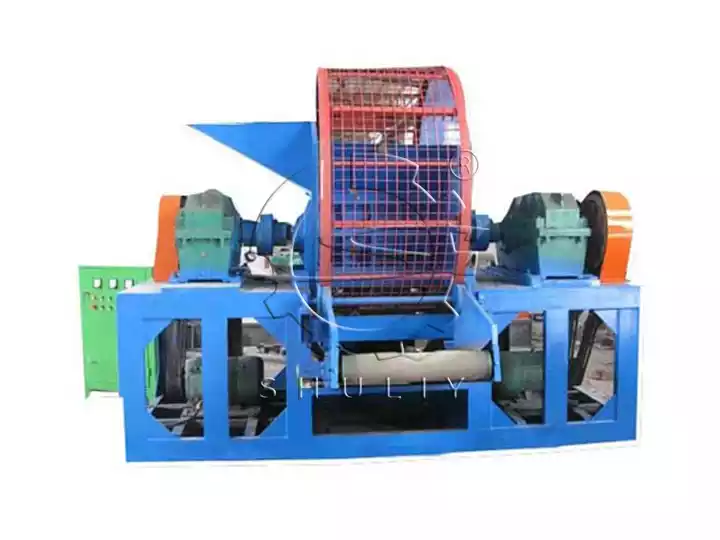

La machine de déchiquetage de pneus industriels est équipée d'un coupeur en alliage à plusieurs étapes, qui peut facilement et avec précision couper des pneus de voiture, des pneus de camion et des pneus d'ingénierie en blocs de caoutchouc uniformes de 50 à 100 mm, et le taux de qualification des fragments atteint jusqu'à 98 %.

Mesurée, la capacité de traitement d'une seule machine est de 2 à 20 tonnes/heure. Les morceaux de caoutchouc peuvent être directement connectés au processus de régénération tel que le broyage, le craquage, etc., et transformés en asphalte en caoutchouc, en combustible biomasse et d'autres produits à forte valeur ajoutée, ce qui aide au recyclage des pneus usagés et réalise la valeur de l'économie circulaire!

Avantages principaux de la machine à déchiqueter les pneus

- Adoption de couteaux forgés en acier allié (comme le matériau 9SiCr, Cr12MoV) et structure de lame amovible, présentant à la fois des caractéristiques de résistance à l'usure et de résistance aux chocs.

- Le système de conduite hydraulique à double axe offre une vitesse de rotation ultra-basse et un couple important, ce qui permet de broyer en continu des pneus jusqu'à 2 mètres de diamètre.

- Le fonctionnement à basse vitesse réduit le bruit à <75dB, et avec le système intégré d'élimination des poussières, les émissions de poussière sont conformes aux normes.

- Prend en charge le broyage mixte des pneus de voiture, des pneus de camion, des pneus de génie civil et des pneus cloutés/à fil, et la taille de décharge peut être contrôlée en changeant l'écran.

Champ d'application de la machine à déchiqueter les pneus

Le broyeur de pneus convertit les pneus usagés en ressources à forte valeur ajoutée grâce à une technologie de broyage physique, et ses applications couvrent les domaines clés suivants :

- Les particules de caoutchouc déchiquetées (50-100 mm) peuvent être utilisées comme additifs modifiés pour les mélanges d'asphalte afin d'améliorer la résistance aux fissures, la réduction du bruit et la durabilité des surfaces routières.

- Les blocs de caoutchouc broyés sont finement traités et largement utilisés pour poser des tapis résilients dans les terrains de soccer, les pistes de course, les aires de jeux pour enfants et d'autres scénarios.

- Produits en caoutchouc : la poudre de caoutchouc peut être utilisée pour produire des joints, des courroies transporteuses, des rouleaux étanches, etc., remplaçant jusqu'à 40 % de l'utilisation de caoutchouc vierge.

- Matériaux de construction écologiques : Des particules de caoutchouc et de la résine sont mélangées pour fabriquer des panneaux acoustiques, des carreaux de sol, etc., qui sont à la fois fonctionnels et décoratifs.

- Grâce à la technologie de craquage thermique, les morceaux de pneus peuvent être convertis en combustible dérivé des pneus (TDF) avec une valeur calorifique de 35MJ/kg, qui peut être utilisé dans les fours à ciment et les centrales électriques pour remplacer le charbon.

- Dans l'industrie automobile, les granulés de pneus peuvent également être utilisés pour fabriquer des composants tels que des coussinets anti-vibrations et des garnitures de frein.

- Après que les blocs de caoutchouc broyés ont été sélectionnés et triés magnétiquement, le fil d'acier et les fibres peuvent être séparés, le fil d'acier est renvoyé au four pour la fusion, et la poudre de caoutchouc est utilisée dans la production de caoutchouc recyclé, avec un taux d'utilisation globale de plus de 98%.

Comment fonctionne ce déchiqueteur industriel ?

- Le moteur du broyeur de pneus entraîne l'arbre de couteau ou le rotor à tourner à basse vitesse via le système de transmission pour fournir la puissance nécessaire au déchiquetage.

- Les couteaux haute résistance sur la plaque de coupe découpent les pneus en morceaux par extrusion mutuelle, cisaillement et déchirement.

- Les fragments entrent dans l'écran (par exemple, un écran en maille circulaire ou un écran à tambour), les morceaux de caoutchouc qui respectent la taille (par exemple, 50-100 mm) sont évacués directement, et les fragments surdimensionnés retournent au bac de concassage pour être recyclés.

- L'outil de coupe coupe le fil d'acier à l'intérieur du pneu de manière synchronisée, et le matériau broyé sépare le fil d'acier et le caoutchouc grâce à un équipement de séparation magnétique.

Paramètres de la machine de recyclage des pneus

| Modèle | 900 | 1000 | 1200 | 1500 | 1800 | |

| Pouvoir | 64.5 | 94.5 | 157 | 188.5 | 328.5 | |

| Capacité | 2Ton/h | 4Ton/h | 5-6Ton/h | 8-10Ton/h | 15-20Ton/h | |

| Taille de l'hôte | 4*2.2*2.8 | 5*2.6*3.2 | 5*2.6*3.2 | 20*10*3.5 | 20*12*4 | |

| Poids | 10Ton | 13Ton | 15,8Ton | 18,6Ton | 26Ton | |

| Surface au sol | 9*5*2.8m | 10*6*3.2m | 10*6*3.2m | 20*10*3.5m | 20*12*4m | |

| Taille d'alimentation | <900mm | <1000mm | <1200mm | <1200mm | <1400mm | |

| Taille de sortie | 50mm | 60mm | 60mm | 75mm | 100mm | |

| Diamètre de la lame | 360mm | 440mm | 510mm | 580mm | 650mm | |

| Épaisseur de la lame | 50mm | 50mm | 60mm | 75mm | 100mm | |

| Nombre de lames | 16 | 16 | 18 | 20 | 18 | |

| Matériau de la lame | Couteau en alliage composite | |||||

| Taille de la bande transporteuse | 7200*950 | 7200*1150 | 7200*1350 | 7200*1350 | 7200*1550 | |

Que vous soyez un centre de traitement des déchets, une entreprise de produits en caoutchouc recyclé ou un entrepreneur en recyclage de pneus, il y a toujours un broyeur de pneus dans notre série qui correspond précisément à vos besoins en capacité et à votre planification budgétaire.

Bien sûr, nous fabriquons également une large gamme d'équipements de traitement des pneus, y compris des séparateurs de jantes et des unités de déchiquetage et de criblage. Contactez-nous maintenant pour un programme en tête-à-tête avec l'un de nos ingénieurs.