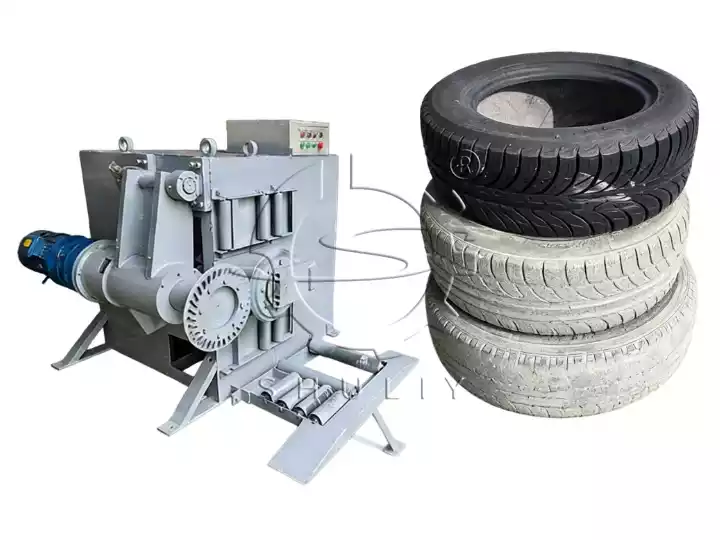

The tire half cutting machine is developed for the disassembly and processing of scrap tires. It is ideal for the pre-treatment of small to medium-sized tires. Utilizing a stable and reliable hydraulic drive system with a high-strength cutting structure, it precisely splits entire tires into two halves. This provides standardized raw material support for subsequent processes such as steel cord separation and rubber crushing.

- Processing target: small to medium-sized waste tires

- Core function: split tires into two halves

- Processing capacity: 2–3 tires/minute

- Maximum tire diameter: ≤1400mm

- Application industries: tire recycling, reclaimed rubber processing, solid waste treatment

This equipment features a compact structure, smooth operation, and simple handling, serving as essential foundational equipment for enhancing tire recycling efficiency and reducing labor costs.

applications of tire splitter machine

As a key piece of equipment in the tire pretreatment process, it is widely used in tire recycling stations, reclaimed rubber plants, and environmental solid waste treatment enterprises.

By rapidly splitting whole tires in half, it significantly improves the operational efficiency of subsequent processes such as cutting, shredding, and steel cord separation. It also reduces the manual labor required for disassembly, enhancing the overall continuity and safety of the production line.

tire half cutting machine parameters

| Article | spécification |

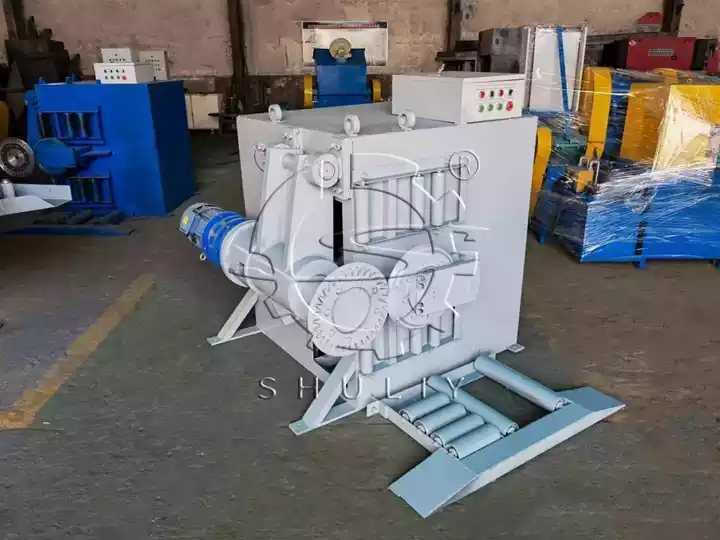

| Machine Name | Hydraulic Tire Splitter |

| Max Tire Diameter | ≤ 1400 mm |

| Cutting Capacity | 2–3 tires / minute |

| Puissance du moteur | 4 kW + 3 kW |

| Tension | 380V / 50Hz |

| Machine Size (L×W×H) | 1850 × 1450 × 1500 mm |

| Poids | 1200 kg |

| Cutting Type | Hydraulic Half Cutting |

advantages of tire tread cutter

- Highly targeted: specifically designed for tire splitting, delivering consistent cutting results that meet core recycling process requirements.

- High efficiency: capable of continuous operation, ideal for batch tire processing.

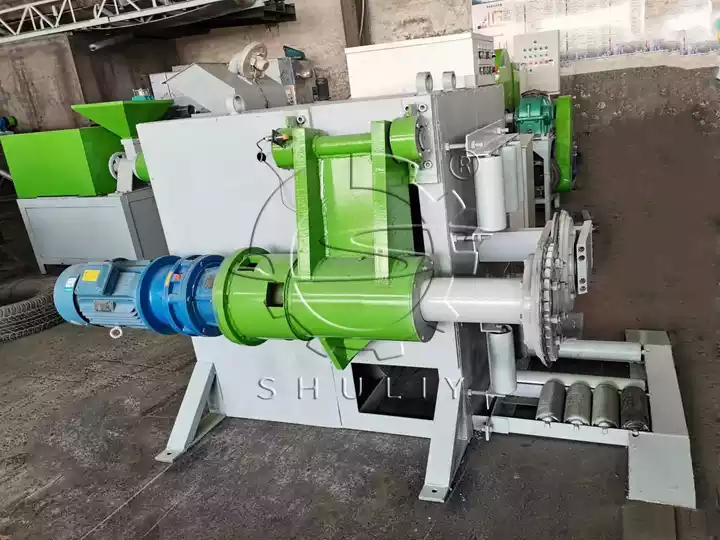

- Powerful and stable: dual motor + hydraulic system combination ensures smooth and robust cutting performance.

- Robust structure: heavy-duty construction with minimal operational vibration guarantees safe operation.

- Low maintenance: clear layout, minimal wear parts, and low long-term maintenance costs.

- Versatile adaptability: processes small to medium-sized tires of varying materials and thicknesses.

how this tire cutting machine work?

The tire tire half cutting machine operates its cutting mechanism through a hydraulic system.

- During operation, the tire is secured within the work area.

- A hydraulic cylinder drives a high-strength cutting tool downward, applying continuous and stable pressure to the tire.

- Under hydraulic force, the blade splits the tire longitudinally from the top along a preset path, achieving a “split-tire” processing effect.

The entire process is coordinated by the motor and hydraulic systems, ensuring smooth operation, precise cutting, and maintaining both tire-separation efficiency and safety.

In addition to this equipment, we offer a variety of tire-cutting solutions for our customers, including models and configurations such as slide-type tire cutters and OTR tire-cutting machines. These cater to diverse tire sizes, production capacity requirements, and process configurations. Contact us to explore the most suitable tire recycling equipment solution for your specific operational needs.