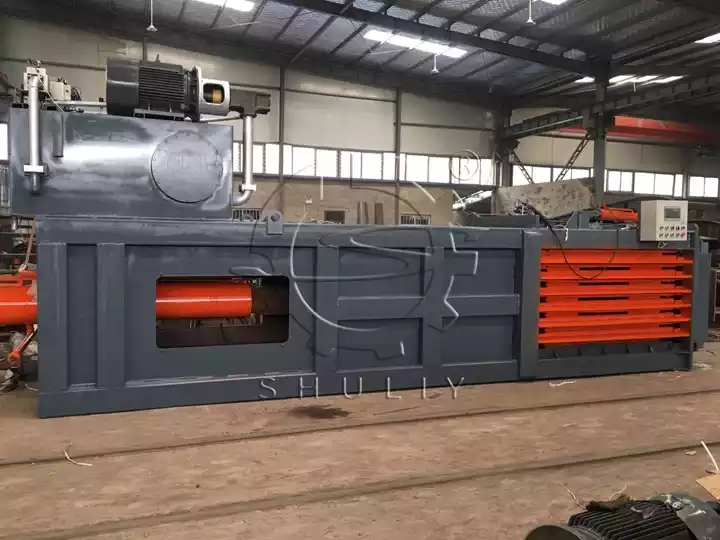

The horizontal tire baling machine is designed for the physical compression processing of scrap automotive tires and large-sized tires. Utilizing a hydraulic cylinder system, the machine compresses tires into uniform bales, significantly reducing volume for convenient transportation and storage.

Equipped with microcomputer-controlled PLC, the device offers simple operation, stable performance, and reliable functionality, meeting the production demands of various scrap tire recycling enterprises.

We offer two specifications, capable of producing 4-5 bales per hour. Models can be selected based on tire dimensions and compression requirements, or customized to meet specific client specifications.

specifications of hydraulic tire baling press

Our SLS-200T and SLB-200T tire baling machine models now feature newly added hydraulic cylinders and compression devices. Equipped with a combined high-low pressure system delivering up to 2000 kN of force, they offer simple operation and stable, reliable performance.

Both balers are compatible with tires of a diameter ≤1m, with a feeding size of 1800×1130mm, making them versatile solutions for different waste tire processing requirements.

| Paramètre | SLS-200T | SLB-200T |

| Pressure | High-low pressure association 2000KN | High-low pressure association 2000KN |

| Taper | With door type | With door type |

| Threading type | 4 pcs wire manual type bundling | 6-8 pcs wire manual type bundling |

| Electronic control system | PLC Automatic intelligent control cabinet | PLC Automatic intelligent control cabinet |

| Master cylinder | Diameter Φ351*1, stroke (length) 3.7 meters | Diameter Φ351*1, stroke (length) 3.7 meters |

| Upper cylinder | 2pcs | 152*125*70mm |

| Master oil pump | Double vane pump | Double vane pump |

| Main Power | 37w*1 | 45w*1 |

| Conveyor motor | 5,5 kW | 5,5 kW |

| Working speed | 4 bales/h | 5 bales/h |

| Feeding size | 1800*1130mm | 1800*1130mm |

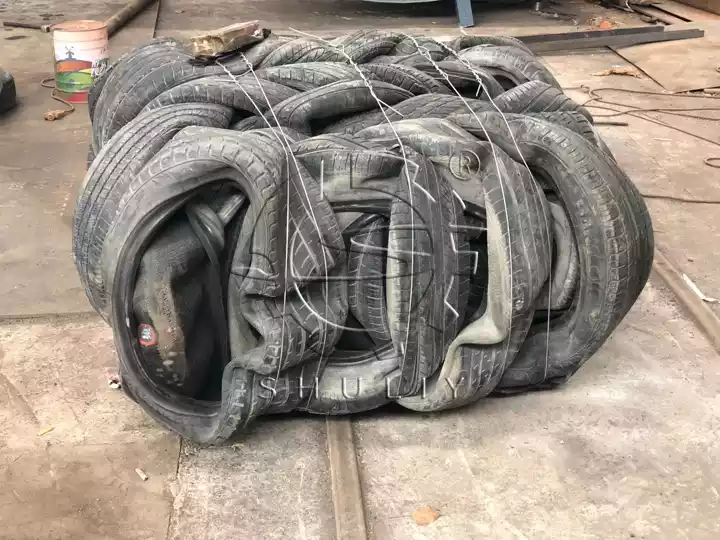

| Bale size | W 113*H 85*L 170cm (adjustable) | W 125*H 125*L 170cm (adjustable) |

| Bale weight | Waste tire: 700-800kg/bale Suit for the tire diameter ≤1m | Waste tire: 1500kg/bale Suit for the tire diameter ≤1m |

| Conveyor size | 9500*1750mm | 9500*1900mm |

| Cooling system | Water cooling | Water cooling |

| Poids de la machine | 17.5 tons | 22 tons |

| Plate thickness | 16mm, material q345/355 | 16mm, material q345/355 |

horizontal tire baling machine advantages

- High compression ratio: 160 tons suitable for standard automotive tires, 200 tons capable of processing large tires up to a diameter ≤ 1 meter.

- Energy-efficient and eco-friendly: the hydraulic system features low noise and minimal energy consumption, saving approximately 33% power compared to similar products.

- User-friendly operation: PLC intelligent control allows customizable block length settings, ensuring simple operation and easy mastery.

- High-capacity conveying: wear-resistant, slip-proof conveyor belt with strong load capacity ensures continuous, efficient feeding.

- Flexible Installation: rapid setup without requiring specialized sites or infrastructure.

- Customization capabilities: special models and functions tailored to specific customer requirements.

- High stability: imported hydraulic components guarantee long-term stable and reliable operation.

- Complete system package: includes baler main unit and feeding conveyor belt for a fully integrated system.

hotizontal tyre baler working principle

The horizontal hydraulic tire baling machine uses a hydraulic system to drive a piston that compresses tires laterally:

- Waste tires are fed into the baler’s compression chamber via a conveyor belt.

- The hydraulic system controls the piston to apply high pressure, compressing tires into uniform bales.

- Compressed tire bales can be smoothly ejected through the discharge port.

- Block length can be freely adjusted via PLC system settings.

- Different pressure models accommodate various tire sizes: 160-ton units suit standard automotive tires (≤800mm), while 200-ton models handle large tires (up to 1-meter diameter).

The machine operates smoothly with low noise, delivers excellent compression results, significantly reduces storage space, and facilitates subsequent transportation.

Choose our factory’s horizontal hydraulic tire balers for more efficient waste tire compression, easier transportation, and space-saving storage! We also offer vertical type tire baling machines to meet a wide range of production needs. Contact us today for the perfect solution tailored to your business!