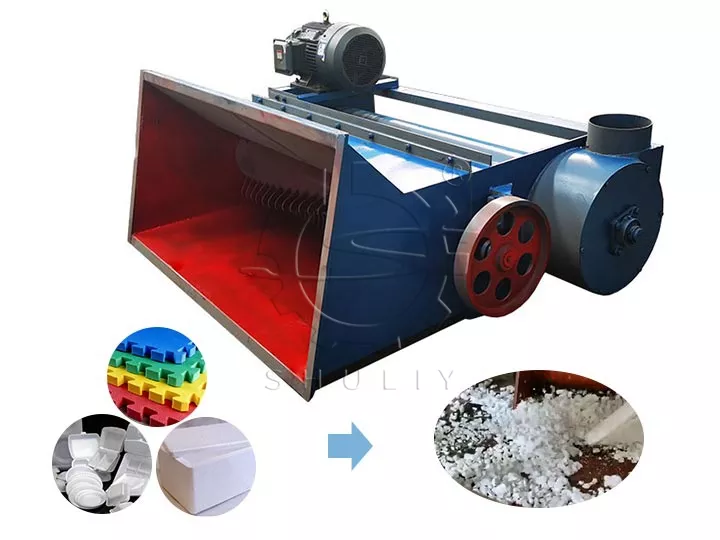

Le broyeur/broyeur de mousse EPS fournit une solution efficace pour le traitement des déchets de mousse EPS. Il réduit la mousse à une taille gérable. Idéal pour traiter les déchets de mousse EPS provenant du transport de coussinets de protection, de colis postés et d'autres produits fragiles en verre/céramique.

Ce broyeur de recyclage de mousse est capable de broyer des blocs de PSE en petits flocons dont la taille varie de 5 mm à 50 mm. Facilitant ainsi le stockage, le transport et le retraitement ultérieurs. La machine peut produire jusqu'à 500 kg/h.

Matières premières pour machine de broyage de mousse

Si elles ne sont pas manipulées correctement, la mousse EPS, la mousse PE, etc. peuvent provoquer une grave pollution de l'environnement. EPS Foam Crusher est spécialement conçu pour le polystyrène expansé et peut aider de nombreuses industries à économiser et à recycler la mousse plastique.

- SPE : boîtes d'emballage, matériaux d'isolation.

- UE : utilisé dans la production de sièges et de coussins.

- PPE : principalement utilisé dans les pièces automobiles et les matériaux d'emballage.

- EPE : matériaux d'isolation, matériaux d'emballage.

- PVC : fabrication de matériaux de construction, de matériaux de décoration, etc.

- Autres mousses : différents types de mousses, telles que PPO (polyphénylène éther), PIR (polyisocyanate), etc.

Mousse EPS après écrasement

Sur la photo, vous pouvez voir des déchets de polystyrène EPS qui ont été broyés en morceaux compacts. La mousse EPS broyée peut être transformée en d’autres produits, ainsi que d’autres mousses plastiques.

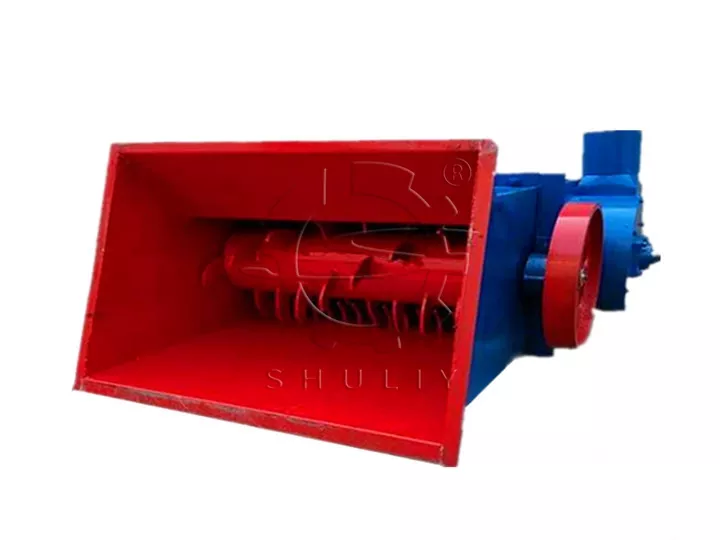

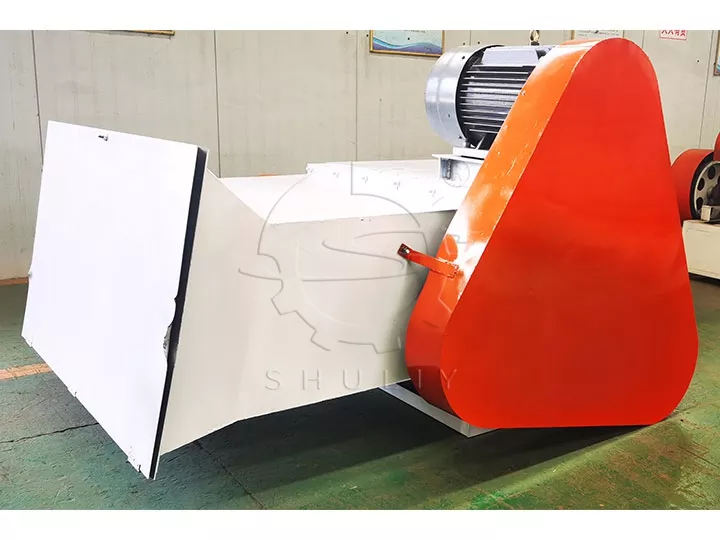

avantages du broyeur de mousse horizontal

Les broyeurs de mousse sont populaires dans le monde entier, en particulier dans les pays et régions qui mettent l'accent sur la protection de l'environnement et le recyclage des ressources. Les machines de notre entreprise ont été expédiées vers de nombreux pays, tels que l'Allemagne, les États-Unis, l'Inde, le Brésil, l'Afrique du Sud, le Nigéria, le Kenya, le Mexique, l'Indonésie, l'Arabie Saoudite, etc. La machine offre les avantages significatifs suivants.

- Adopter un design silencieux, avec un faible bruit.

- Une grande trémie d'alimentation rend l'alimentation plus pratique.

- Réduisez la poussière générée dans le produit fini moulu.

- Faible consommation d'énergie, fonctionnement simple, faibles coûts d'exploitation et de maintenance.

- Convient au traitement de mousse de différentes formes et densités, avec une forte polyvalence.

- Adopter des lames amovibles, qui peuvent être démontées et affûtées individuellement une fois les lames émoussées.

- La conception horizontale permet d'occuper moins d'espace horizontalement, ce qui facilite l'aménagement dans une usine ou un lieu de travail limité.

- La conception horizontale contribue à la répartition uniforme des matériaux dans la chambre de concassage, améliore l'efficacité du concassage et garantit l'uniformité du produit fini.

principe de fonctionnement de la machine de broyage de polystyrène

- Alimentation: la mousse de polystyrène tombe dans l'ouverture d'alimentation du pulvérisateur de mousse.

- Découpe et concassage : après son entrée dans la machine, la mousse est découpée et broyée par des lames ou des couteaux. Ces lames tournent généralement à grande vitesse et coupent la mousse en petites particules. Les lames sont en acier et sont solides et durables.

- Dépistage: les particules de mousse coupées et pulvérisées passent à travers un tamis pour séparer les particules de différentes tailles. Cette étape permet d'obtenir un produit fini de la granulométrie souhaitée.

- Collection: les particules de mousse tamisées et broyées sont collectées dans des conteneurs appropriés. Ces particules peuvent être traitées ultérieurement pour fabriquer de nouveaux produits en mousse ou pour d'autres applications.

Comment prolonger la durée de vie du broyeur de polystyrène ?

- Entretien et nettoyage: nettoyer le matériel, lubrifier et inspecter régulièrement les pièces d'usure.

- Fonctionnement correct: éviter la surcharge et maintenir une alimentation uniforme.

- Conditions environnementales: maintenir un environnement sec et une température adaptée.

- Utiliser des pièces de qualité: choisissez des pièces d'origine et évitez d'utiliser des pièces de qualité inférieure ou incompatibles.

Les broyeurs de mousse et de plastique sont tous deux des équipements utilisés pour pulvériser des matières plastiques. La rectifieuse de mousse est spécialement utilisée pour le traitement de la mousse, avec une optimisation particulière dans la conception et le traitement des lames.

Le broyeur de plastique est plus vaste et convient au traitement d'une variété de matériaux plastiques, y compris les plastiques durs, les plastiques souples, etc. Pour cette machine, vous pouvez en apprendre davantage sur des informations détaillées à partir de Machine de recyclage de broyeur de plastique PP PE.

paramètres de la machine de concassage de mousse EPS

| Taper | Taille hors tout (mm) | Taille de l'orifice d'alimentation (mm) | Puissance (KW) | Capacité (KG/H) |

| 800 | 1250*1290*660 | 800*600 | 5.5 | 250-300 |

| 1000 | 1250*1530*660 | 1000*600 | 5.5 | 300-350 |

| 1200 | 1300*1730*700 | 1200*600 | 7.5 | 400-450 |

| 1500 | 1600*2200*800 | 1500*800 | 11 | 450-500 |

La capacité de traitement et d'autres paramètres du broyeur de mousse varient en fonction du modèle spécifique. Vous devez choisir le modèle approprié en fonction de la demande réelle avant d'acheter. N'hésitez pas à nous contacter pour plus de détails, nous pourrons vous recommander le modèle qui vous convient.

De plus, notre usine produit également d'autres machines pour le recyclage de la mousse EPS, telles que machines de fusion à chaud de polystyrène et compacteurs à froid. Ici, vous pouvez trouver un équipement adapté, nous sommes impatients de collaborer avec vous.