La machine de fusion de mousse EPS est un dispositif de recyclage très efficace qui combine des fonctions de broyage et de fusion. Elle peut broyer les plastiques en mousse déchets (tels que EPS, EPE, EPP, etc.) en particules puis les faire fondre et les comprimer en blocs ou particules plastiques réutilisables à l’aide d’un mécanisme de chauffage par vis.

Cet équipement réalise un rapport de compression allant jusqu’à 90:1, réduisant considérablement le volume de mousse plastique et les coûts de transport et de stockage associés. C’est un choix idéal pour le recyclage et la réutilisation des mousses dans des secteurs tels que l’emballage, la construction, les appareils électroménagers et les industries de la pêche.

Avantages de la machine de fusion à chaud EPS de Shuliy

- En utilisant le chauffage par vis, la fusion et la technologie de compression, avec un rapport de compression allant jusqu’à 90:1, permettant d’économiser efficacement l’espace de transport et de stockage.

- Empreinte compacte, rendement élevé, faible bruit et facile à opérer et à entretenir.

- Large éventail d’applications, capable de traiter divers matériaux en mousse tels que EPS, EPE, EPP, XPS et PSP.

- La température est entièrement contrôlable tout au long du processus, empêchant la mousse de brûler ou de ne pas fondre.

- Les lames sont amovibles et peuvent être affûtées individuellement, prolongeant leur durée de vie.

- Soutient des solutions de recyclage personnalisées pour répondre à des exigences d’application diversifiées.

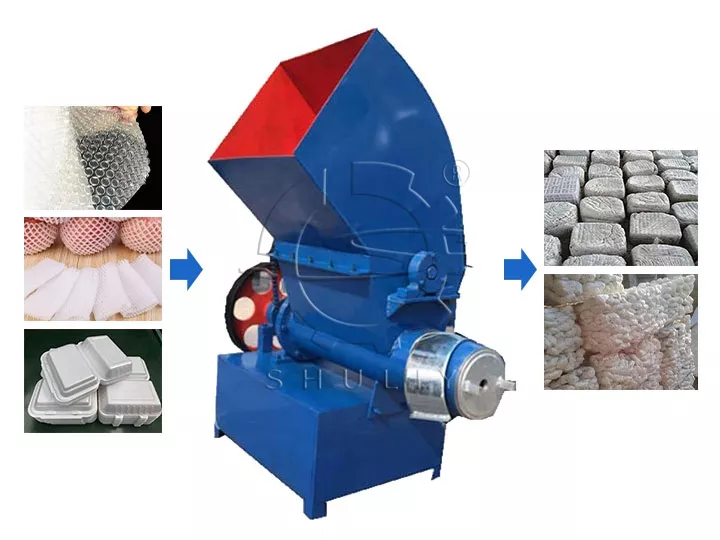

matières premières pour machine de fusion de mousse EPS

Cet équipement peut traiter une variété de matériaux en mousse, y compris :

- EPS (polystyrène expansé) : largement utilisé pour l’emballage d’appareils, l’isolation des bâtiments, l’isolation des toitures, la protection du mobilier, les aquariums et la préservation des produits agricoles et aquatiques.

- EPE (mousse éthylène-propylène) : couramment utilisé для la protection des instruments de précision et des objets fragiles lors du transport.

- EPP (mousse éthylène-propylène-propylène) : appliqué dans les pièces automobiles, les équipements sportifs et les boîtes d’isolation.

- XPS, PSP : matériaux en mousse couramment utilisés dans les industries d’isolation de la construction et d’emballage alimentaire.

La densité des panneaux de mousse est généralement de 10-45 kg/m³. En raison de sa légèreté et de son grand volume, le coût de transport est fortement accru.

Nous avons deux moyens de réduire le volume de mousse : l’un consiste à utiliser un compresseur pour pressage à froid, et le rapport de compression est généralement de 1:50 ; l’autre consiste à utiliser une machine à fusion à chaud pour un traitement de fusion à chaud, faire fondre la mousse et la refroidir en blocs, afin d’obtenir une variation de la densité volumique.

spectacle final de grumeaux de mousse

Les produits finis produits par la machine de fusion EPS ont une densité élevée et une réduction de volume de plus de 90 %, ce qui réduit fortement les coûts de stockage et de transport.

Les produits finis peuvent être retraités en une variété de produits plastiques pour réaliser la réutilisation des ressources, économisant jusqu’à 70 % des coûts de traitement des déchets pour les entreprises chaque année et améliorant les avantages économiques globaux.

Prenant en exemple une grande usine de tissage plastique, l’utilisation de 30 % de matières premières recyclées peut réduire les coûts de 80 000 à 200 000 dollars américains, réduisant ainsi considérablement les coûts de production.

étapes de recyclage du densificateur de mousse EPS

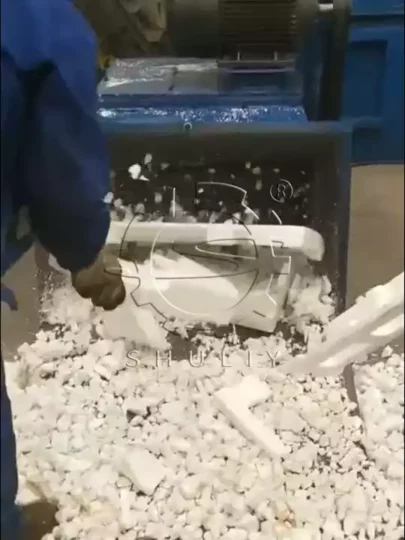

- Tout d'abord, le système de chauffage démarre pour préchauffer la vis à la température nominale, puis les déchets de polystyrène sont jetés dans la trémie de la machine.

- Ensuite, un pré-broyeur doté de deux ou quatre arbres de coupe rotatifs le brise en morceaux de 10 à 50 mm, qui sont forcés dans le système d'extrudeuse par la vis.

- L'élément chauffant chauffe la mousse et la fait fondre à la bonne température. La mousse EPS est plastifiée en une masse fondue homogène à travers le système d'extrusion et est extrudée en continu par la vis au cours du processus.

Paramètres de la machine de recyclage de fusion à chaud EPS

La puissance de chauffage, la capacité de traitement, la température de fusion et le mode de contrôle des différents modèles de machines seront différents et doivent être sélectionnés raisonnablement en fonction des besoins réels et de l'échelle de production. N'hésitez pas à nous contacter pour recommander le type de machine de fusion de mousse EPS le plus approprié et obtenir un devis.

| Taper | Dimensions externes(mm) | Taille du port d’alimentation(mm) | Puissance de configuration(kw) | Puissance d’entrée(kw) | Capacité (kg/h) |

| SL-220 | 1500*800*1450 | 450*600 | 15 | 3 | 100-150 |

| SL-880 | 1580*1300*850 | 800*600 | 18.5 | 3 | 150-200 |

| SL-1000 | 1900*1580*900 | 1000*700 | 22 | 3 | 200-250 |

Précautions pour la machine thermofusible de concassage de mousse

Lors de l'utilisation de la machine de fusion de mousse EPS, il faut prêter attention aux points suivants, et l'entretien et la maintenance de la machine thermofusible de concassage de mousse doivent garantir que l'équipement fonctionne pendant une longue période et un fonctionnement efficace de la clé.

- Entretien de l’équipement : nettoyer régulièrement les lames, vérifier le système de chauffage et lubrifier les pièces mécaniques, pour assurer un fonctionnement normal.

- Remplacement des pièces usées : pour les pièces qui s’usent facilement, comme les lames, les remplacer à temps pour garantir l’efficacité du traitement et la longévité de la machine.

- Adaptabilité des matériaux : s’assurer que le matériau en mousse mis dans la machine réponde aux spécifications et exigences de la machine afin d’éviter d’endommager l’équipement.

- Contrôle de la température : pendant le fonctionnement, ajuster la température de fusion appropriée en fonction des différents matériaux en mousse pour assurer l’efficacité du traitement.

- Prévention du colmatage : veiller à empêcher l’entrée de la mousse EPS dans la machine de fusion de mousse de se bloquer pour assurer un flux matériel fluide.

cas réussis

La plupart des entreprises de l’industrie du recyclage seront confrontées à la réutilisation de mousse plastique. L’un de nos clients de Arabie Saoudite dirige une usine d’assemblage d’électronique et d’appareils électroménagers, qui génère beaucoup de matériaux d’emballage en mousse de rebut. Comme leur compresseur ancien était trop lent et ne fonctionnait pas correctement, ils ont choisi une nouvelle machine de fusion EPS pour augmenter leur taux de recyclage.

Au cours de l'année écoulée, ils ont économisé au moins 15 000 TP4T en coûts de mise en décharge, ont réalisé plus que des bénéfices supplémentaires en vendant la mousse fondue et ont augmenté l'efficacité de l'entrepôt d'au moins 30%.

Notre société propose des services complets de consultation avant-vente, d'installation et de mise en service globales, de formation au fonctionnement et de maintenance après-vente pour garantir que votre équipement fonctionne toujours dans les meilleures conditions. Si vous êtes intéressé par nos produits ou si vous avez des questions, n'hésitez pas à nous contacter et nous sommes impatients de coopérer avec vous.