La ligne de production de plateaux à œufs comprend un système de fabrication de pâte, une machine de moulage de pâte, un séchoir et un système d'emballage. Ce processus démontre comment les vieux papiers peuvent être utilisés pour créer des plateaux à œufs respectueux de l'environnement, durables et abordables. En raison de ces caractéristiques, les plateaux à œufs sont très demandés pour le stockage et le transport des œufs dans les supermarchés, les restaurants et les maisons.

Dans cet article, nous détaillerons le processus complet de production de plateaux à œufs, y compris l'équipement et les matériaux nécessaires. De plus, nous proposons des équipements de qualité et une variété de solutions de fabrication de barquettes à papier. Si vous souhaitez démarrer une entreprise de fabrication de plateaux à œufs, n'hésitez pas à nous contacter !

matières premières pour la ligne de production de plateaux à œufs

La principale matière première pour les plateaux à œufs est le vieux papier, facilement disponible et peu coûteux. Cela inclut généralement les matériaux d'emballage tels que les vieux journaux, les vieux cartons et les boîtes en carton.

Il est préférable de s’assurer que les vieux papiers sont propres, exempts de contaminants et d’épaisseur uniforme.

L'eau est un autre matériau important utilisé dans la préparation de la pâte. Il est essentiel de disposer d’une source d’eau fiable, non contaminée et de qualité constante.

Affichage du produit final

Après une série de lignes de production de plateaux à œufs, vous pouvez enfin obtenir le plateau à œufs léger, solide et doté d'une bonne absorption de l'humidité. De plus, le coût de fabrication des plateaux à œufs est faible et économique. Une variété de tailles et de formes de bacs à papier peuvent être produites pour s'adapter à différentes tailles et types d'articles.

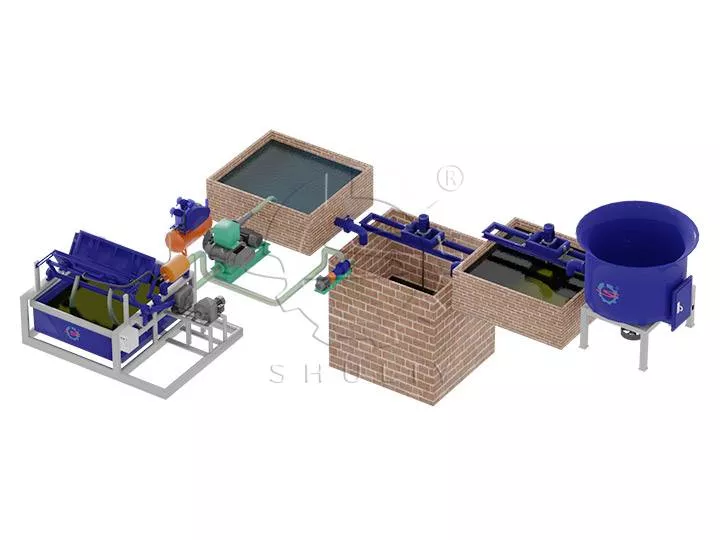

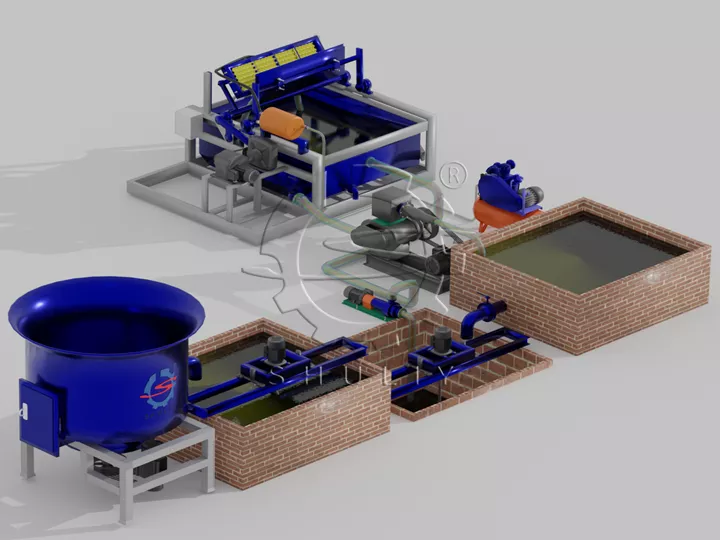

cartons d'oeufs faisant le flux de travail de l'usine

Le flux de travail de la ligne de production de plateaux à œufs est automatisé. Il comprend la série de machines suivante : machine à pulper → machine à former des plateaux à œufs → machine de séchage → baleuse de plateaux à œufs.

Parmi eux, la presse à balles est un équipement optionnel, vous pouvez choisir de l'acheter en fonction de la situation.

De plus, vous pouvez choisir une presse à chaud pour plateau à œufs, qui rend la surface du plateau à œufs plus lisse et plus facile à vendre.

principales machines pour fabriquer des bacs à papier

En fonction des besoins du client en termes de capacité de production, de taille et de forme du produit, nous fabriquons différents modèles de chaque machine de la ligne de production de plateaux à œufs. Dites-nous ce dont vous avez besoin et nous vous recommanderons la meilleure machine.

machine à pâte à papier

La machine à pulper disperse et mélange uniformément les fibres de la pulpe par agitation, puis élimine les impuretés par tamisage. Cela permet à la pulpe d'atteindre la consistance et la viscosité appropriées.

Il suffit généralement d'un seul ouvrier pour mettre des vieux papiers et de l'eau dans la machine dans un rapport de 1:3. Si vous souhaitez changer la couleur du plateau à œufs, vous pouvez ajouter un colorant ici. Ce processus fournit le matériau de base pour les processus ultérieurs.

plateau d'oeufs de moulage de pâte faisant la machine

La pâte est d'abord acheminée vers la machine de moulage. Il est ensuite réparti uniformément sur la surface du moule à l'aide d'une goulotte pour assurer une répartition uniforme de la pâte.

Selon le moule utilisé, les machines à former des plateaux à œufs peuvent produire des plateaux de différentes tailles. Le processus de formation est automatisé, garantissant la cohérence et l'uniformité des plateaux produits.

machines à sécher

Le séchoir élimine rapidement l'humidité du produit en plateau à œufs qui a été moulé au niveau de sécheresse souhaité. Ce processus est nécessaire pour garantir que les plateaux à œufs sont solides et peuvent supporter le poids des œufs.

Il existe différentes méthodes de séchage des plateaux à œufs, en fonction de l'échelle de production, des ressources disponibles et du climat.

Nous avons le choix entre trois types d'équipements de séchage, notamment des séchoirs à œufs multicouches en continu, des salles de séchage et des séchoirs au four à briques.

Machine de mise en balles de plateaux à œufs

La presse à plateaux à œufs peut emballer automatiquement les plateaux à œufs de manière soignée et ordonnée selon les spécifications définies et les méthodes d'empilage pour le stockage, le transport et la vente.

Cela améliore non seulement l’efficacité de l’emballage, mais garantit également la qualité globale et l’apparence des produits.

Presse à chaud pour plateaux à œufs

La presse à chaud du plateau à œufs rend la surface du plateau à œufs déjà moulé plus lisse, plus ferme et plus solide en chauffant et en appliquant une certaine pression, ce qui se vend mieux.

Cela permet également de garantir que les plateaux à œufs ne se déforment pas ou ne se cassent pas facilement pendant le transport, le stockage et l'utilisation.

paramètres techniques des machines de fabrication de plateaux à œufs

Les machines de la ligne de production de plateaux à œufs sont conçues pour la production en grand volume de plateaux en papier et le rendement dépend de la taille et de la conception des machines. Différents modèles de machines à plateaux à œufs ont été développés pour traiter de 1 000 à 7 000 plateaux à papier. Voici les principaux paramètres pour votre référence.

| Modèle | Capacité | Consommation de papier | Consommation d'eau | Énergie utilisée | Ouvrier |

| SL-3*1 | 1000-1500 pièces/heure | 120kg/heure | 300kg/h | 32 kW/h | 3-4 |

| SL-4*1 | 1500-2000 pièces/h | 160kg/h | 380kg/heure | 45 kW/h | 3-4 |

| SL-3*4 | 2000-2500 pièces/heure | 200kg/h | 450kg/heure | 58 kW/h | 4-5 |

| SL-4*4 | 3000-3500 pièces/heure | 280kg/h | 560kg/heure | 78 kW/h | 4-5 |

| SL-4*8 | 4000 pièces/heure | 320kg/heure | 600kg/heure | 80 kW/h | 5-6 |

| SL-5*8 | 5000 pièces/heure | 400kg/h | 750kg/heure | 85 kW/h | 3-4 |

| SL-5*12 | 6000 pièces/heure | 480kg/h | 900kg/heure | 90 kW/h | 3-4 |

| SL-6*12 | 8000 pièces/heure | 640 kg/heure | 1040 kg/heure | 100 kW/h | 3-4 |

avantages de la ligne de fabrication de plateaux à œufs Shuliy

- Fournisseur expérimenté : Shuliy Group est présent dans ce secteur depuis des années, avec plus de 100 lignes de production de plateaux à œufs installées et opérationnelles avec succès dans le monde entier. Notre vaste expérience en exportation vous permet d’économiser du temps et de l’argent.

- Plusieurs options et designs personnalisés : tout d’abord, nous proposons différents modèles de machines à plateaux à œufs. Deuxièmement, vous pouvez personnaliser les moules des plateaux à œufs pour créer différents plateaux. Troisièmement, la même machine peut produire différents types de barquettes.

- Prix d'usine et faible coût : nous avons notre propre usine, nous pouvons donc vous offrir un prix équitable. De plus, nous fournissons la solution la plus adaptée à vos besoins pour vous aider à réduire vos coûts et vos dépenses d’exploitation.

- Ecologique et non polluant : l'ensemble du processus de production des plateaux à œufs ne génère aucune eau usée ni gaz d'échappement. Toute l'eau est recyclée. Et la machine à plateaux à œufs recycle les vieux papiers en produits moulés en pâte à papier biodégradables.

ligne de production de bacs à papier pour moulage de pâte à papier, cas réussis

La ligne de production de plateaux à œufs est devenue une méthode de production efficace, respectueuse de l'environnement et économique, qui a progressivement été largement utilisée dans l'industrie de l'emballage des œufs.

Nos produits de machines sont exportés dans le monde entier et ont été expédiés avec succès dans de nombreux pays, y compris, mais sans s'y limiter, le Cameroun, le Mozambique, le Royaume-Uni, l'Ouzbékistan, le Sénégal, les États-Unis, le Canada, le Kenya, le Zimbabwe, l'Indonésie, le Nigéria, etc.

Si vous avez des questions sur le processus de fabrication des plateaux à œufs, vous pouvez cliquer sur l'article : Révéler le processus complet de production de moulage de plateaux à œufs. Si vous souhaitez plus d'informations détaillées, veuillez nous contacter à tout moment.