The EPS foam melting machine is a highly efficient recycling device that combines shredding and melting functions. It can shred waste foam plastics (such as EPS, EPE, EPP, etc.) into particles and then melt and compress them into reusable plastic blocks or particles using a screw heating mechanism.

This equipment achieves a compression ratio of up to 90:1, significantly reducing the volume of foam plastic and associated transportation and storage costs. It is an ideal choice for foam recycling and reuse in industries such as packaging, construction, home appliances, and fisheries.

Advantages of shuliy EPS hot melting machine

- Utilizing screw heating, melting, and compression technology, with a compression ratio as high as 90:1, effectively saving transportation and storage space.

- Compact footprint, high output, low noise, and easy to operate and maintain.

- Wide range of applications, capable of processing various foam materials such as EPS, EPE, EPP, XPS, and PSP.

- Temperature is fully controllable throughout the process, preventing foam from burning or remaining unmelted.

- Blades are removable and can be sharpened individually, extending their service life.

- Supports customized recycling solutions to meet diverse application requirements.

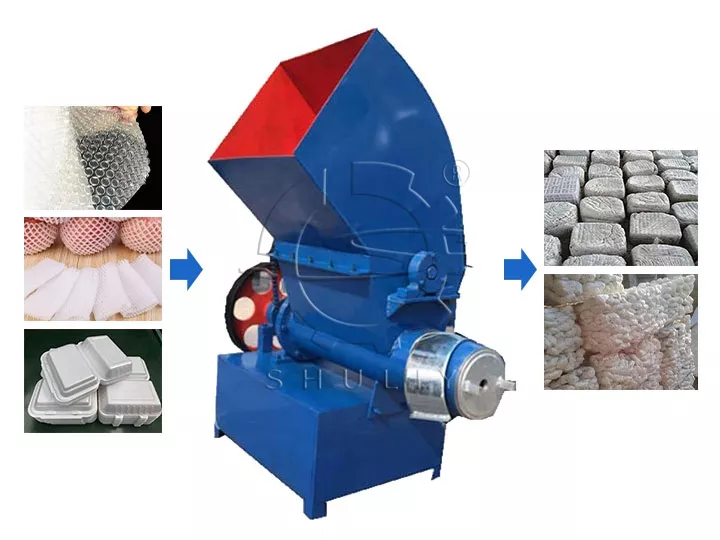

raw materials for EPS foam melting machine

This equipment can process a variety of foam materials, including:

- EPS (expanded polystyrene foam): widely used in appliance packaging, building insulation, roof insulation, furniture protection, fish tanks, and the preservation of agricultural and aquatic products.

- EPE (ethylene propylene foam): commonly used for protecting precision instruments and fragile items during transportation.

- EPP (ethylene propylene propylene foam): applied in automotive parts, sports equipment, and insulation boxes.

- XPS, PSP: commonly used foam materials in the construction insulation and food packaging industries.

The density of foam board is generally 10-45kg/m³. Due to its lightweight and large volume, the transportation cost is greatly increased.

We have two ways to reduce the volume of foam: one is to use a compressor for cold pressing, and the compression ratio is generally 1:50; the other is to use a hot melt machine for hot melting treatment, melt the foam and cool it into blocks, to achieve the change of volume density.

final foam lumps show

The finished products produced by the EPS foam melting machine have high density and a volume reduction of more than 90%, which significantly reduces storage and transportation costs.

The finished products can be reprocessed into a variety of plastic products to achieve resource reuse, saving up to 70% of waste disposal costs for enterprises each year and improving overall economic benefits.

Taking a large plastic weaving factory as an example, using 30% recycled raw materials can reduce costs by 80,000 to 200,000 US dollars, significantly reducing production costs.

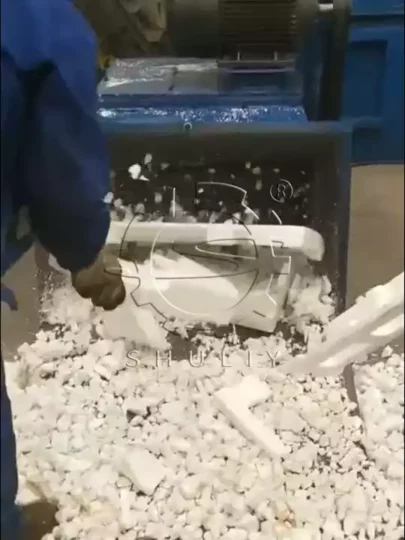

recycling steps of EPS Foam Densifier

- First, the heating system is started to preheat the screw to the rated temperature, and then the waste Styrofoam is thrown into the hopper of the machine.

- Then a pre-crusher with two or four rotating cutter shafts breaks it into 10-50mm pieces, which are forced into the extruder system by the screw.

- The heating element heats the foam and melts it to the right temperature. EPS foam is plasticized into a homogeneous melt through the extrusion system and is continuously extruded by the screw in the process.

EPS hot melting recycling machine Parameters

The heating power, processing capacity, melting temperature, and control mode of different models of machines will be different, which need to be selected reasonably according to the actual needs and production scale. Please feel free to contact us to recommend the most suitable type of EPS foam melting machine and get a quote.

| Type | Outside Dimensions(mm) | Feed Port Size(mm) | Configuration Power(kw) | Inlet Power(kw) | Capacity(kg/h) |

| SL-220 | 1500*800*1450 | 450*600 | 15 | 3 | 100-150 |

| SL-880 | 1580*1300*850 | 800*600 | 18.5 | 3 | 150-200 |

| SL-1000 | 1900*1580*900 | 1000*700 | 22 | 3 | 200-250 |

Foam crushing hot melt machine precautions

When using the EPS foam melting machine needs to pay attention to the following matters, and care and maintenance of the foam crushing hot melt machine is to ensure that the equipment is for a long time and efficient operation of the key.

- Equipment maintenance: regularly clean the blades, check the heating system, and lubricate the mechanical parts, to ensure normal operation.

- Replacement of worn parts: for parts that are easy to wear out, such as the blades, replace them in time to ensure the treatment effect and the life of the machine.

- Material adaptability: ensure that the foam material put into the machine meets the specifications and requirements of the machine to avoid damage to the equipment.

- Temperature control: during operation, adjust the appropriate hot melt temperature according to different foam materials to ensure the treatment effect.

- Preventing clogging: pay attention to preventing the inlet of the EPS foam melting machine from clogging to ensure smooth material flow.

successful cases

Most companies in the recycling industry will face the situation of recycling plastic foam. One of our customers from Saudi Arabia runs an assembly plant for electronics and appliances, which generates a lot of waste foam packaging materials. Because their old compactor was too slow and not working properly, they chose a new EPS foam melting machine to increase their recycling rate.

In the past year, they have saved at least $15,000 in landfill costs, made more than extra profits by selling the melted foam, and increased warehouse efficiency by at least 30%.

Our company provides comprehensive pre-sales consultation, global installation and commissioning, operation training, and after-sales maintenance services to ensure that your equipment always runs in the best condition. If you are interested in our products or have any questions, please feel free to contact us and we look forward to cooperating with you.