The EPS Foam Compactor Machine utilizes a hydraulic system to cold-press and compress EPS plastic foam under low-temperature conditions, thereby enhancing product density and strength.

By achieving a compression ratio of up to 50:1, it produces block-shaped products with densities of 250-350 kg/m³. This not only facilitates storage and transportation but also significantly reduces shipping costs, while providing an efficient solution for recycling waste foam.

This equipment features simple operation, low noise levels, and easy maintenance. It is an ideal choice for furniture packaging, building materials, and waste foam recycling enterprises.

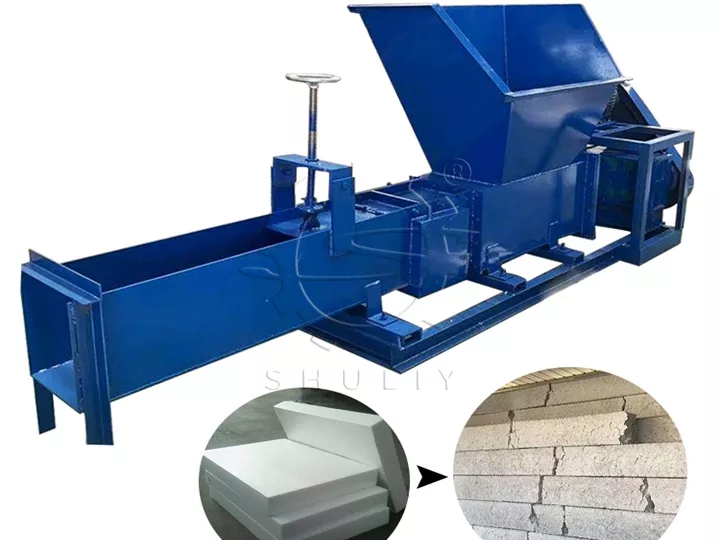

EPS foam compactor raw material

EPS foam cold press machines can process various types and densities of EPS foam(Polystyrene Foam), including:

- Furniture packaging materials: such as packaging foam for sofas, mattresses, etc.

- Food packaging foam: such as fish boxes, EPS trays, EPS containers, etc.

- Construction foam materials: EPS corner beads, insulation boards, foam panels, etc.

- Other EPS products: various EPS foam blocks and sheets.

Custom cold-pressing solutions can be provided based on different raw materials to meet diverse recycling and reuse requirements.

Turn Your EPS Waste into Value

EPS can also be referred to as airpop or foam polystyrene. This versatile material can be used for a variety of purposes, from insulation to protecting products during transportation.

This lightweight but expanding material is not biodegradable, and if it is not compressed, it usually ends up in landfills, causing serious problems. However, by selling compressed EPS blocks, you can generate revenue. So compressed EPS can be a win-win situation for both your business and the environment.

finished product you can get

The increased density and strength of compacted EPS foam block make the foam material more practical and adaptable. The block can be sold for reusing and making frame products and construction moldings, such as crown molding, wall panels, etc. It can also be used for packaging and the manufacture of furniture.

benefits of EPS foam recycling compactor

- High-efficiency compaction: achieves a compression ratio of up to 50:1, reducing foam volume by 30-40 times for convenient storage and transportation.

- Hydraulic cold-press technology: low-temperature cold pressing without chemical additives ensures odor-free, safe, and eco-friendly operation.

- Simple structure, easy operation: user-friendly controls and straightforward maintenance make it suitable for various enterprises.

- Low noise, minimal dust: eco-friendly design reduces operational noise and dust pollution.

- Integrated shredding unit: directly processes large foam panels for streamlined production and processing.

- Customizable design: select feed inlet sizes to accommodate diverse foam types and output requirements.

How styrofoam recycling densifier works?

- Put the EPS foam materials to be processed into the hopper.

- Crush the large EPS foam into small pieces.

- Compress the EPS foam using pressure and hydraulic technology.

- Compacting and pressing by screw extrusion.

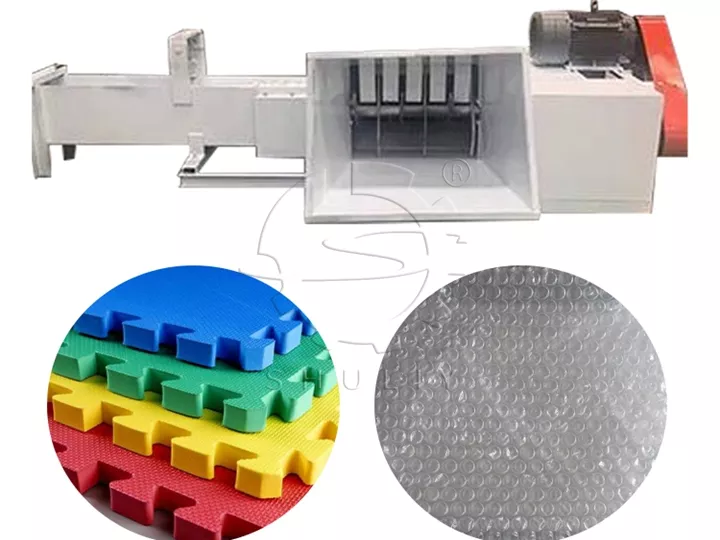

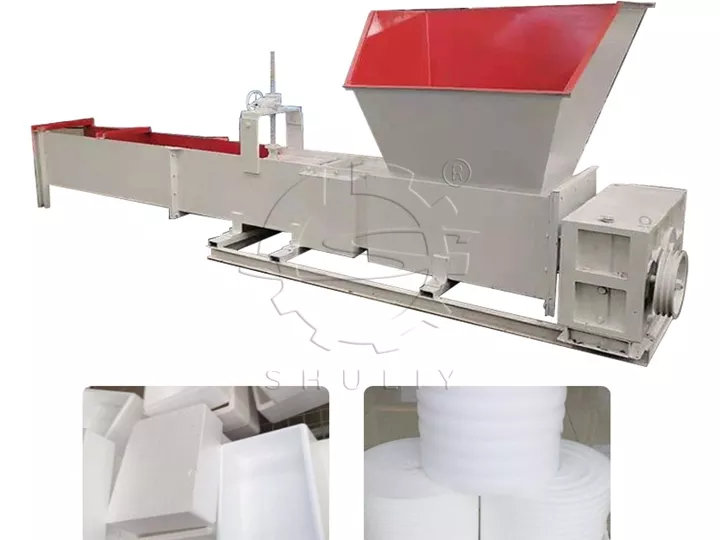

two types of foam compaction equipment

Shuliy has vertical and horizontal types of EPS foam compactor cold press equipment to choose from. They have their characteristic advantages. Which one to choose needs to be considered comprehensively based on specific production needs and process requirements.

Horizontal EPS foam compactor

- Space-saving: occupies less floor area, suitable for factories or workshops with limited space.

- Convenient operation: the operator can easily operate and observe from the front of the machine, which is convenient for monitoring the production process.

- Easy to maintain: the structure is relatively simple, and maintenance and upkeep are relatively easy, reducing maintenance costs.

- Good visibility: the operating interface and press area are usually easier for the operator to observe, allowing for easy adjustments and monitoring.

Vertical EPS foam compactor

- Suitable for products with special shapes: it is more convenient to manufacture products with certain special shapes and can cope with more production demands.

- More stable pressure transfer: since the product is placed horizontally, it may be easier to realize uniform pressure transfer to ensure the quality of the finished product.

- Suitable for large products: often suitable for large products or where a larger press space is required, providing greater manufacturing flexibility.

- Higher productivity: for certain production processes, the ability to handle more products at the same time increases productivity.

parameters of styrofoam recycling compactor

Below are two of our vertical foam cold compactor models. We can also customize other machine sizes and outputs for different needs.

| Type | Machine size (mm) | Inlet size (mm) | Power (KW) | Capacity (kg/h) |

| 300 | 3000*1400*1400 | 1100*800 | 11 | 150 |

| 400 | 4600*1600*1600 | 1200*1000 | 22 | 250 |

hot-selling foam recycling machinery

The rise of the plastic recycling industry around the world, makes the EPS foam compactor have a better market prospect in these markets. Especially in developed countries and more industrialized regions.

Shuliy EPS foam compactor plastic recycling machinery has shipped to many countries such as Dominica, Malaysia, Canada, Egypt, Morocco, the United States, Germany, Japan, Korea, India, Brazil, Russia, Australia, and Turkey.

A producer of high-quality cod in the United States operates a large fishing company. Due to the size of the operation, many Styrofoam boxes were used to contain fresh fish. A large number of waste boxes were generated.

In the past, they had no choice but to send this waste to a landfill. After learning about our foam compactor recycling solution, they purchased and installed the machine from our factory and successfully recycled the discarded Styrofoam boxes.

If you need a machine for foam-type recycling, we also offer the EPS foam crushing and hot melting machine. You can click to view the EPS Foam Melting Machine For Styrofoam Plastic Recycling. Should you have any machinery requirements, please feel free to contact us at any time.