The egg tray machine is made of waste paper as raw material, through the pulp molding process, it can produce many kinds of pulp molding products such as egg tray, egg carton, fruit tray, coffee cup tray and so on.

Our factory provides various models of machines with different capacities from 1000pcs/h to 7000pcs/h, which are suitable for small family workshops, medium-sized enterprises and large-scale processing factories.

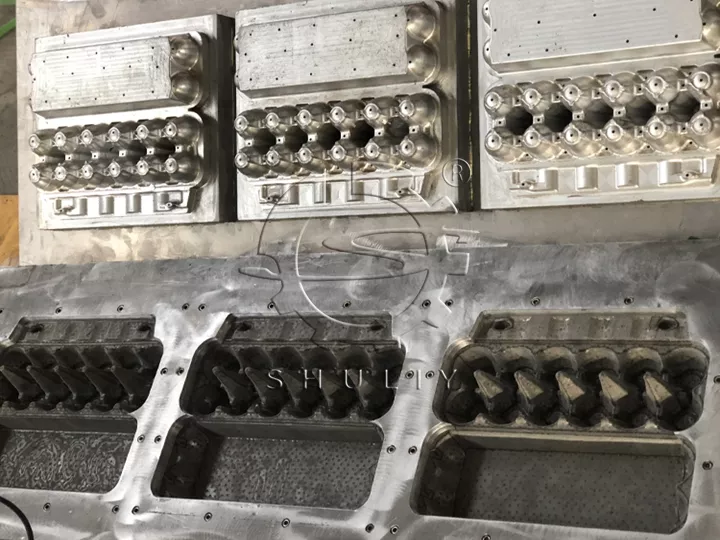

The egg tray machine is compact, easy to change molds, supports customized production, and has the ability to reproduce 1:1 high-precision molds. It can meet different customers’ individual demands for product color, thickness, size and shape, and is the first choice equipment for investment in pulp packaging industry.

wide Applications of egg tray making machine

Egg tray molding machines are used in a wide range of applications in the packaging field, mainly for the packaging and protection of eggs and other fragile products. The following are some of the common applications of paper tray machines:

- Egg packaging: The most common application of egg tray machines is for egg packaging. They can produce egg tray cartons of various sizes and capacities for protecting eggs from damage during transportation and storage.

- Fruit packaging: Egg trays can also be used to package fruits, such as strawberries, raspberries, and grapes, which help to prevent the fruits from crushing each other and being damaged during transportation.

- Glass packaging: Fragile glass products, such as glasses, plates, and vases, can be packaged in egg cartons to reduce the risk of breakage during transportation and storage.

- Food packaging: Egg trays can also be used to package other food products such as chocolates, candies, and pastries to prevent them from being damaged during transportation and display.

In summary, paper egg carton machines are used in a wide range of applications, not limited to egg packaging, but also in the packaging and protection of many fragile products, providing vital support for product safety and integrity.

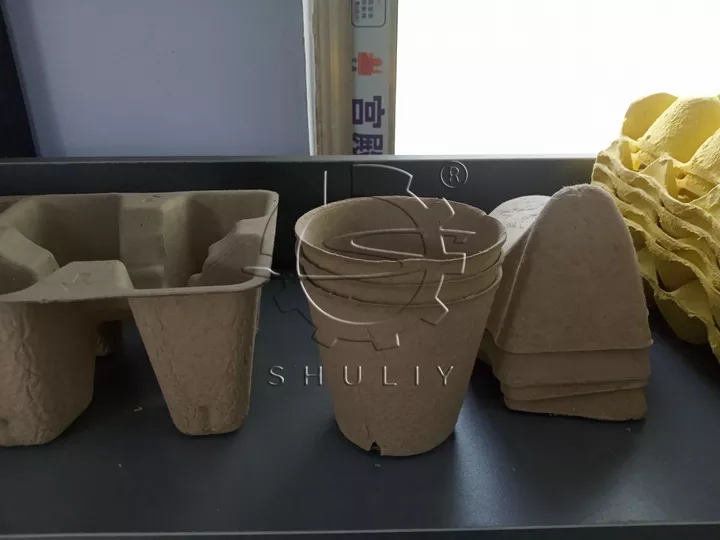

egg tray machine finished products display

The finished products produced by the egg tray making machine usually finished products have the following characteristics: solid structure, various specifications, customizable, environmentally friendly materials, wide applicability, can be neatly stacked, and so on.

A variety of molds to show

working principle of egg tray forming machine

The entire process is continuous, and the molding machine can consistently produce egg tray cartons to meet production demands. This automated process produces finished products efficiently and consistently and is the core equipment of the egg tray production line.

Pulp or Plastic Supply

First, pulp or plastic feedstock is supplied to the egg tray molding machine’s feed system. These raw materials are usually prepared in advance to ensure molding quality and consistency. Pulp is manufactured by the sustainable paper processing crusher and advanced paper pulp system, which is the front-end equipment of the egg tray machine.

Injection or Slurry Injection

Pulp or plastic feedstock is injected into the mold, usually through a nozzle or injection system. The raw material fills the mold, filling the desired space.

Molding and compaction

After the raw material is filled into the mold, the molding machine applies pressure and vibration to ensure that the raw material is evenly distributed in the mold and tightly compacted to form the desired shape of the egg tray carton.

Demolding

Once the molding is complete, the mold moves to the demolding area. The molding machine may employ suction cups or other devices to easily remove the egg tray carton from the mold.

Finished Product Conveying or Stacking

The egg cartons are conveyed to the next stage, usually stacking, packaging, or shipping. Finished products can be neatly stacked for subsequent handling or packaging.

pulp paper Tray Machine Parameters

The following is a partial display of the main parameters of the three different egg tray machine models, if you want to know more details about the supporting and other model parameters, please contact us at any time.

| Model | SL-1000-3X1 | SL-2500-3X4 | SL-7000-6X8 |

| Capacity | 1000pcs/h | 2500pcs/h | 7000pcs/h |

| Voltage | 380V,50HZ | 380V,50HZ | 380V,50HZ |

| Power | 38kw | 55kw | 120kw |

| Weight | 2500kg | 4000kg | 10000kg |

| Overall dimension | 2600*2200*1900mm | 2900*1800*1800mm | 3200*2300*2500mm |

| Paper consumption | 80kg/h | 200kg/h | 480kg/h |

| Water consumption | 160kg/h | 400kg/h | 960kg/h |

| Drying method | Dry naturally or use a dryer | Brick kiln drying or multi-layer dryer | Brick kiln drying or multi-layer dryer |

paper pulp molding machine’s main features

Egg tray molding machines offer many benefits that make them ideal for packaging eggs and other fragile products. Here are some of the main advantages of egg tray molding machines:

- The equipment can ensure that each egg tray is of uniform size and stable quality, which helps to maintain brand image and product consistency.

- The size, shape, color and printing content of the egg tray can be freely customized according to the market demand to meet different customer groups.

- Pulp egg trays are well structured with excellent shock absorption and cushioning performance, which can effectively prevent eggs and other fragile products from being damaged during transportation and storage.

- In addition to eggs, it can also be applied to the packaging of fruits, ceramics, glass products and many other fragile products, enhancing the use value of the equipment.

- Finished egg trays are designed in a standardized way, easy to be stacked neatly, saving storage and transportation space and improving logistics efficiency.

Because of these advantages and the factory’s mass production, our egg tray forming machines have been successfully exported to many countries, including Sri Lanka, Lebanon, Saudi Arabia, Senegal, Bolivia, Guatemala, France, Jordan, Uzbekistan, Sudan, Zambia, Kenya, Cameroon, etc.

FAQ About egg tray machines

Customers often ask a series of questions when purchasing an egg tray molding machine to ensure that the equipment they choose meets their needs. Here are some common questions and the corresponding answers:

What is the production capacity of this egg tray molding machine?

Our production capacity for the egg tray machine is 1,000 to 15,000 pieces per hour. We can provide different sizes of machines to meet your capacity needs.

Can you provide after-sales support and spare parts supply?

Yes, we offer full after-sales support including training, maintenance service, and spare parts supply to ensure that your machine is always running efficiently.

What is the delivery time for the equipment?

Delivery time depends on the machine model and customization options. We will provide you with the exact delivery time after the order is confirmed and ship the machine as soon as possible.

Are reference customers or case studies available?

Yes, we can provide previous customer references or successful cases so that you can understand the performance and effect of our equipment in real applications.

What are the prices and payment methods?

Prices will vary according to machine models, configurations, and customization options. We will provide a detailed quote and discuss payment options and terms with you.

Customers’ questions may vary depending on their specific needs, so you are welcome to communicate with us in detail and get satisfactory answers before purchasing to ensure that you choose the right egg tray machine for your production needs.