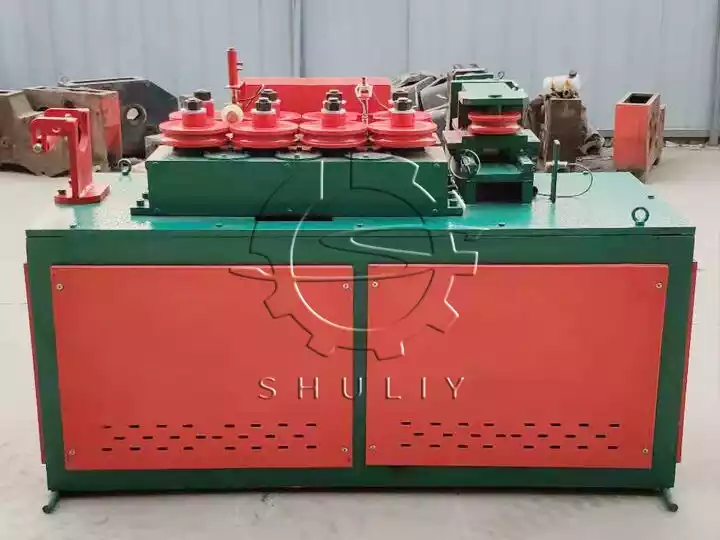

Einführung der CNC-Rohrbiegemaschine mit einem modernsten CNC-Steuerungssystem im Herzen. Diese vielseitige Maschine eignet sich perfekt für eine Vielzahl von Branchen, darunter Luft- und Raumfahrt, Automobilherstellung, Energieausrüstung und Fitnessgeräte, die alle Ihre Pfeifenbiegeanforderungen versorgen. Es kann einen vollen Bereich von Spezifikationen von φ10-100 mm, 10-24 mm, 20-51 mm, 30-76 mm bis 40-100 mm verarbeiten.

Was es auszeichnet, ist seine Fähigkeit, in einem einzigen Betrieb komplizierte dreidimensionale Kurven zu erstellen und die Effizienzgrenzen herkömmlicher Methoden zu übertreffen. Dies bedeutet, dass es zuverlässige, multi-spezifische Verarbeitungslösungen für Branchen wie Schiffbau, Petrochemikalien und Kernenergie bietet.

Kernvorteile der CNC -Röhrchenbender

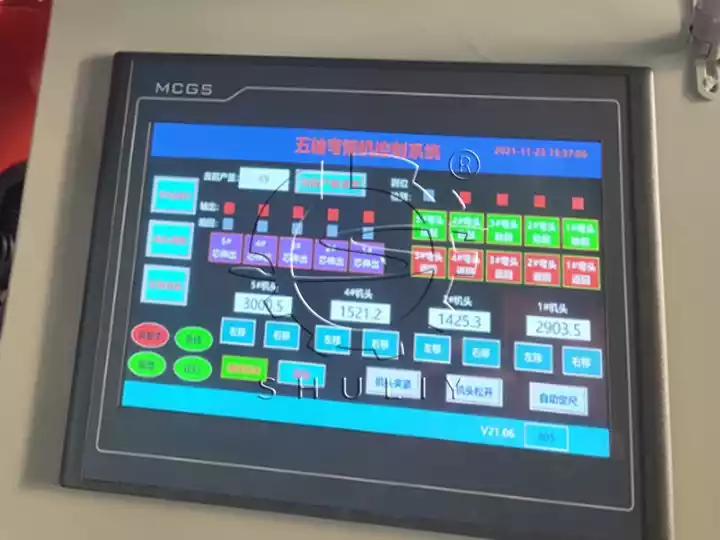

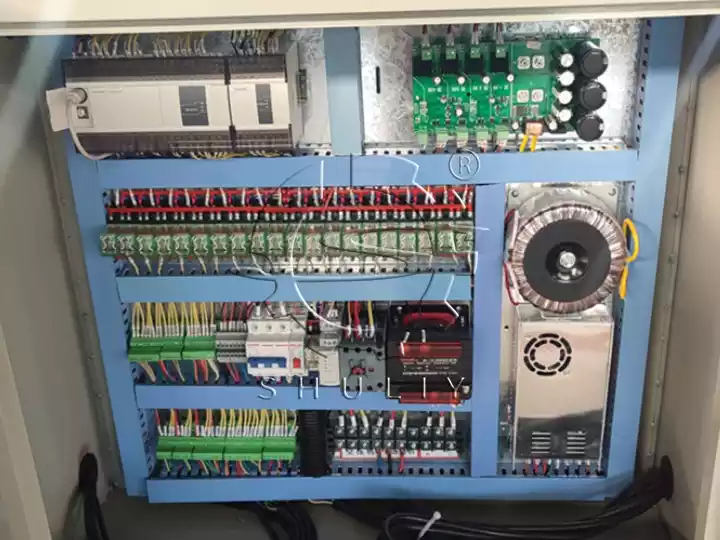

- Die Einführung eines intelligenten CNC -Systems garantiert eine wiederholbare Positionierungsgenauigkeit von ± 0,1 mm, die den Anforderungen der Luft- und Raumfahrt-, Automobil- und anderen Präzisionsverarbeitungsfelder perfekt auswirkt.

- Es unterstützt die Rohrverarbeitung für Durchmesser im Bereich von φ10 bis 100 mm, wobei die Notwendigkeit häufiger Formänderungen beseitigt werden und es ideal für eine Vielzahl von Anwendungen, einschließlich Schiffen, Petrochemikalien und Fitnessgeräten.

- Mit vollständig automatisierter Fütterung, Biegung und Schneiden in ein System hat der Effizienz um über 50% gestiegen, was kontinuierliche Batch -Vorgänge ermöglicht.

- Das System bietet dreidimensionale Raum und mehrwinkelfreies Biegen, so dass es einfach ist, U-förmige, s-förmige und andere benutzerdefinierte Rohrdesigns zu erstellen.

- Außerdem verfügt diese CNC-Rohrbiegemaschine über Vibrationen und Abriebfestigkeit, was sie für industrielle Umgebungen mit hoher Intensität gut geeignet ist, die rund um die Uhr arbeiten.

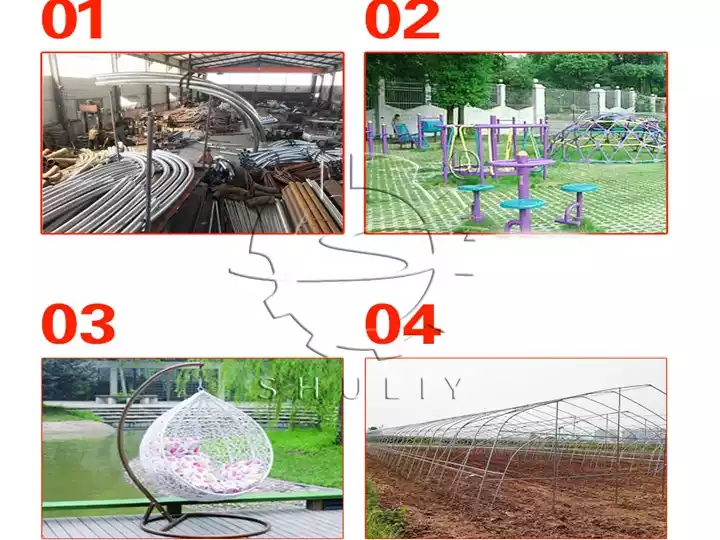

Anwendungsbereich von CNC -Rohrbiegermaschinen

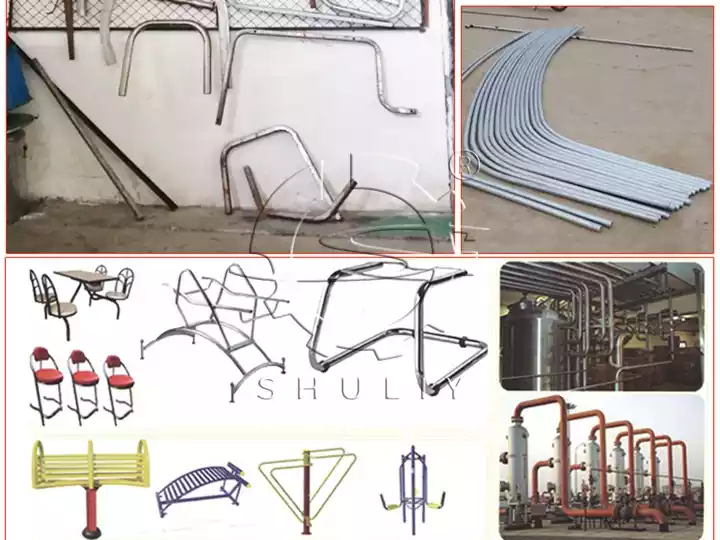

- Die CNC -Rohrbiegemaschine ist vielseitig und kann in verschiedenen Bereichen wie Bauwesen, Outdoor -Aktivitäten, Landwirtschaft und sogar zu Hause verwendet werden, um sich in mehreren Branchen in mehreren Branchen anzupassen.

- Es verarbeitet präzise Metallrohre für den Bau, erzeugt geformte Rahmen und unterstützt Teile, die den Anforderungen großer Veranstaltungsorte und Stahlgebäude mit komplizierten Kurven gerecht werden.

- Es passt auch gut an Fitnessgeräte im Freien, Spielplatzstrukturen und Landschaftsinstallationen an, wobei langlebige und ergonomische Metallkomponenten erzeugt werden, die den Elementen standhalten können.

- Darüber hinaus werden Treibhausbögen, Bewässerungsrohre und Stützstrukturen für Aquakulturausrüstung effizient hergestellt, die ein hohes Kompressionsbiegedesign aufweisen, das die Stabilität dieser Einrichtungen erhöht.

- Zuletzt bietet es personalisierte Designs für künstlerische Möbel, Beleuchtung, Hänge von Stühlen und mehr, die eine mehrdimensionale Biegung von Materialien wie Edelstahl und Aluminiumlegierung ermöglichen.

automatische Rohrbendermodelle und Spezifikation

Unsere Werksfabrik stellt eine Vielzahl von CNC -Rohrbiegemaschinen her, und Sie finden ihre detaillierten Spezifikationen, die in der folgenden Abbildung dargestellt sind:

| Modell | Modell 38 | Modell 51 | Modell 76 | Modell 100 |

| Biegebereich | 10-24 mm | 20-51 mm | 30-76 mm | 40-100 mm |

| Winkelbereich | 0-180 Grad | 0-180 Grad | 0-180 Grad | 0-180 Grad |

| Hauptgeschwindigkeit | 20 U / min | 20 U / min | 16 U / min | 16 U / min |

| Maschinengröße | 800*650*900 mm | 850*700*930 mm | 940*780*960 mm | 1020*800*960 mm |

| Wandstärke | 1-3 mm | 1-4 mm | 1-5mm | 2-6 mm |

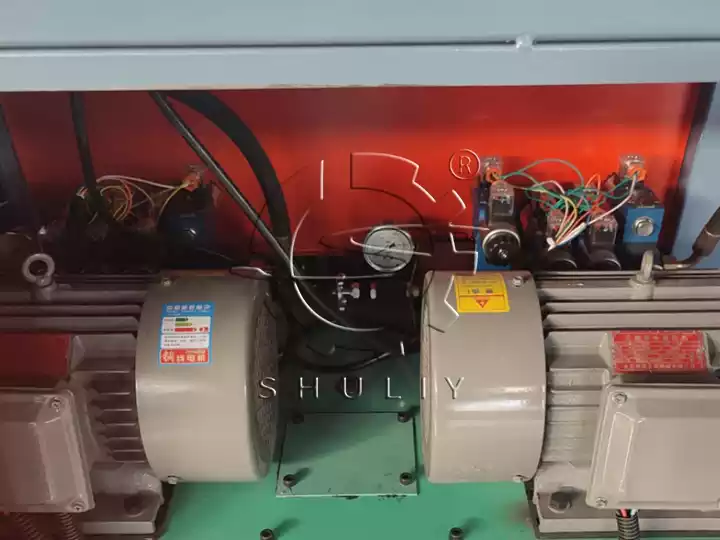

| Motorleistung | 3KW 4-pole (National Standard) | 3KW4 Pole (National Standard) | 4KW6 Pole (National Standard) | 5,5 kW 6 Pole (nationaler Standard) |

| Eingangsspannung | Dreiphasen 380 V | Dreiphasen 380 V | Dreiphasen 380 V | Dreiphasen 380 V |

| Maschinengewicht | 230 kg | 260 kg | 290 kg | 360 kg |

| Modell | Modell-5 hydraulischer CNC | Modell-9-Hydraulik-CNC | Modell-11 hydraulischer CNC |

| Stahlstangendurchmesser | 4-28 mm | 4-32 mm | 4-36 mm |

| Rundrohrdurchmesser | 10-50 mm | 10-60 mm | 10-60 mm |

| Ovalrohrdurchmesser | 30*80 mm | 30*80 mm | 30*80 mm |

| Maschinengewicht | 700 kg | 900 kg | 1050 kg |

| Hydraulikmotorkraft | 3KW | 3,8 kW | 5,5 kW |

| Reisegeschwindigkeit | 12m/min | 12m/min | 12m/min |

| Reisemotor | 4KW | 4KW | 4KW |

| Gesamtabmessungen | 1100*1500*1200 mm | 1100*1800*1200 mm | 1100*1800*1200 mm |

Neben der CNC -Rohrbiegermaschine, über die wir zuvor gesprochen haben, stellen wir auch eine Vielzahl von Biegergeräten her, die für Baustadelstangen ausgelegt sind. Dies umfasst Bogenbiegerautomaten und Plattenstangen -Bender -Maschinen. Schauen wir uns einen kurzen Blick darauf an, was diese beiden Arten von Maschinen tun können!

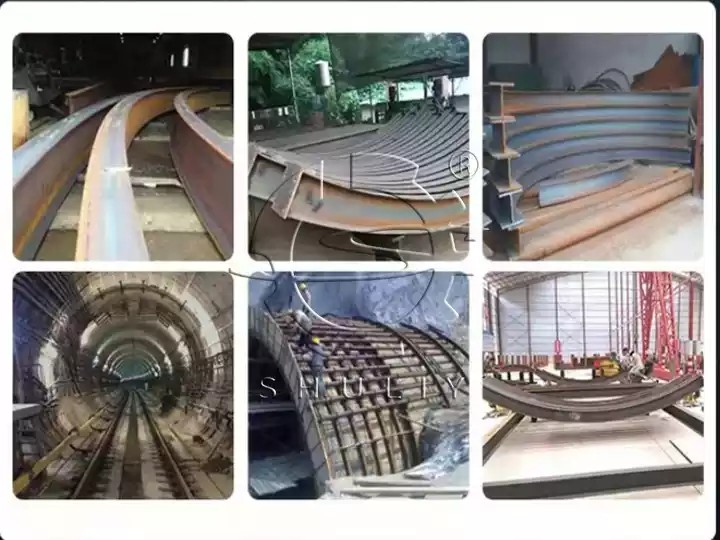

Stahlhydraulikbogenmaschine

Diese Ausrüstung wird speziell zum Biegen schwerer Stahl gefertigt, wobei eine breite Palette von Profilen wie I-Träger, U-Träger, C-Träger und Winkelstahl entspricht. Es wurde entwickelt, um die einzigartigen Anforderungen komplexer gekrümmter Strukturen in verschiedenen Bereichen wie Bau, Infrastruktur und industrielle Fertigung gerecht zu werden, wodurch vielseitige Stahl in mehreren Szenarien gebildet werden.

- Es biegt genau I-Strahlen, Kanalstahl und andere Profile, um Träger und Säulen in Stahlkonstruktionsanlagen, Stadien und vielem mehr zu unterstützen.

- Die Maschine verarbeitet U-Träger und C-Träger für die Verstärkung von Tunnelwänden, was sie perfekt für U-Bahn-, Bergbau- und andere Tunnel-Ingenieurprojekte macht.

- Es kann quadratische Stahl, runde Stahl und andere Materialien biegen, um Hauptträger, Leitplanken und Anschlussteile für Brücken zu erstellen.

- Darüber hinaus wird die Biegung von Winkel- und Kanalstahl zur Bildung von Bogenmitgliedern für petrochemische und Energieausrüstung angepasst, um Bedarf wie Getriebepipeline zu befriedigen.

- Schließlich kann es künstlerische Formen aus quadratischem und runden Stahl für dekorative Strukturen in Gewerbeflächen wie Kiele und Treppenhandläufe schaffen.

Verarbeitungsbereich

- 25# I-Beam

- 140h Stahl/14 Kanalstahl

- 150 Rundrohr/150 Quadratrohr

- Gesamtleistung: 3+3+3 kW

- Biegeradiusbereich: 2m

- Druckhydrauliksystemdruck: 16mpa

- Hauptantriebsradgeschwindigkeit: 7,7R/min

- Maschinengewicht: 1600 kg

- Gesamtabmessungen: 250*150*80 cm

Operation Video

Vollautomatische Plattenstange Biegemaschine

Es ist zum effizienten Biegen von Stahlstäben gebaut, sodass es einfach ist, verschiedene Spezifikationen schnell zu formen. Es verfügt über einen automatisierten Prozess zum Füttern, Biegen und Scheren, sodass eine einzelne Maschine täglich über 10.000 Stücke herstellen kann. Dies senkt nicht nur die Arbeitskosten, sondern eignet sich auch perfekt für Anwendungen im Bau, Brücken, vorgefertigte Komponenten und vieles mehr.

- Es kann Batch-Biege für Balken, Säulen, Bodenplatten und andere Baustärke bewältigen und die Notwendigkeit von Erdbebenresistenten, Bankstäben und anderen komplizierten Formen bedienen.

- Die Maschine verarbeitet den Brückenpier- und Säulenreihen genau sowie abdeckte Strahlskelette, um sicherzustellen, dass die Krümmung und der Abstand alle mechanischen Spezifikationen erfüllen.

- Es eignet sich auch hervorragend für die Erzeugung eines Verstärkungsnetzes für vorgefertigte Komponenten wie laminierte Platten und Rohrkorridore.

- Darüber hinaus kann es Stahlbinderknoten-Reifen und vorgefertigte Teile der Bolzenhülle erzeugen, wodurch die Gesamtstabilität von Stahlkonstruktionen durch einen hohen Biegeprozess erhöht wird.

Parameterinformationen

- Hydraulikdruck: 5-16mpa

- Größenmethode: Handbuch/automatisch

- Maschinenleistung: 8 kW

- Luftdruck: 0,4-0,6 MPA

- Formierungsgeschwindigkeit: 5 Sekunden

- Verarbeitungskapazität: 1500-2000/Stunde

- Maschinenkopfverriegelung: Hydraulische Verriegelung

- Winkelfehler: ± 1 °

- Maschinengewicht: 1200 kg

Arbeitsvideo

Wenn es um die Umformung von Bewehrungsstahl geht, hängt die Wahl des richtigen Modells wirklich davon ab, die Spezifikationen Ihres Rohmaterials – wie Rohrdurchmesser und Profilstärke – mit Ihren spezifischen Bedürfnissen abzustimmen, sei es für den Bau, Brücken oder die Herstellung von vorgefertigten Teilen.

Neben unseren CNC-Rohrbiegemaschinen bieten wir eine Reihe weiterer Bewehrungsstahlverarbeitungsmaschinen an, darunter Bewehrungsstahl-Richtmaschinen, Stahlbiegemaschinen und Stahlkreisbiegemaschinen. Zögern Sie nicht, sich noch heute an unser Expertenteam zu wenden, um Details zu den Modellprogrammen und Angeboten zu erhalten!