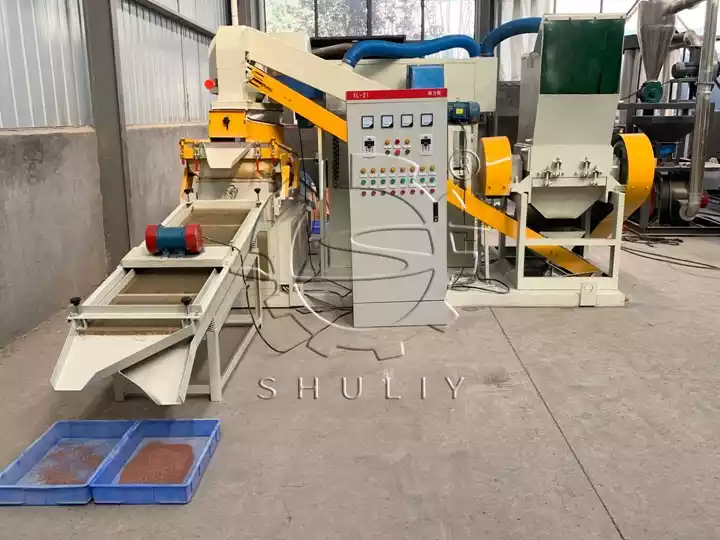

The copper wire granulator is a highly efficient recycling machine specifically designed for processing scrap electrical wires and cables. It precisely strips the insulation from wires, thoroughly separating the copper or aluminum core from the plastic outer sheath. Achieving up to 99.9% separation purity, it boasts a processing capacity of 800-1000kg/h.

Not only does it significantly enhance recycling efficiency, but it also strikes a balance between environmental sustainability and economic benefits. This helps users minimize waste while obtaining high-value renewable resources. With its high degree of automation and user-friendly operation, it is the ideal choice for wire and cable recycling and reuse.

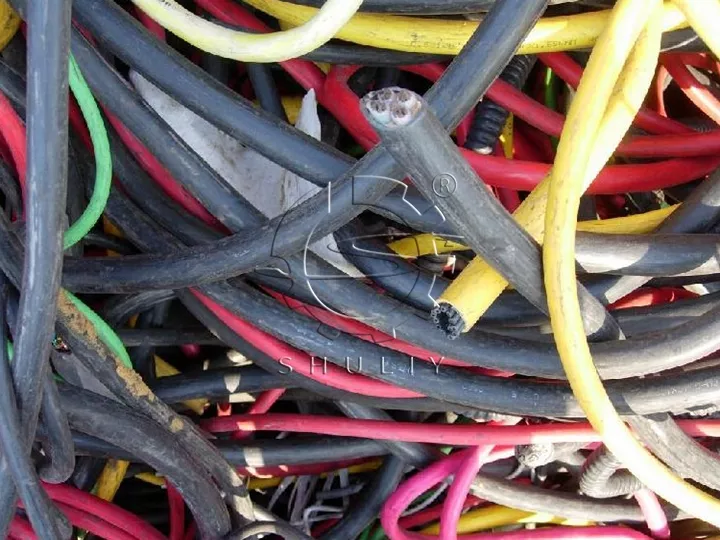

Demonstration of materials that can be handled

The copper wire granulator machines are suitable for processing various types and specifications of scrap electrical wires and cables, including:

- Household wires: such as appliance wires, communication cables, lighting wires, etc.

- Industrial cables: such as power cables, control cables, large equipment wires.

- Automotive wires: vehicle wiring harnesses, motor wiring.

- Other scrap copper and aluminum wires: diameter range 0.1mm to 30mm.

Processed scrap wire is separated into high-purity copper (or aluminum) granules and plastic pellets. This not only conserves resources but also reduces environmental pollution, creating new profit opportunities for the metal recycling industry.

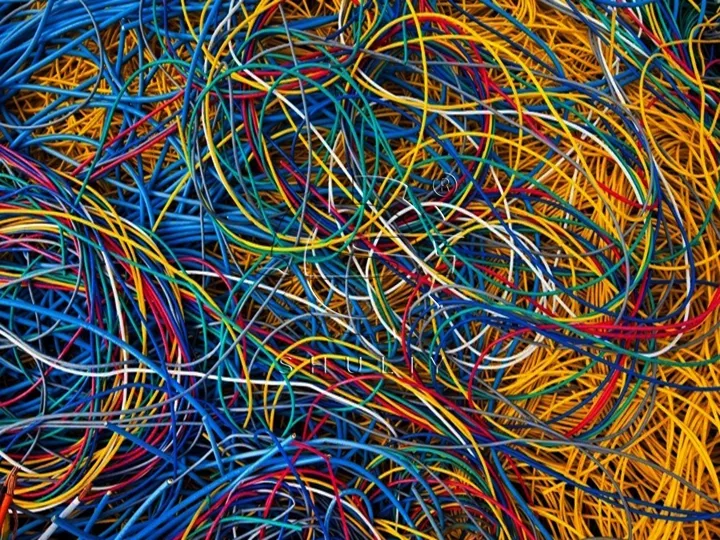

Finished Products you can get

The finished product generated from the treatment of scrap copper wire and cable in a copper wire recycling machine is usually economically efficient, high-purity copper. This high-quality copper can usually be used directly in remanufacturing, such as copper wires, pipes, cables, and so on.

how a copper wire granulator works?

The working principle of the copper cable wire recycling machine relies heavily on mechanical forces and physical processes. It converts waste copper wires and cables into high-quality copper materials for further reuse and recycling through the steps of cutting, separating, and collecting. This automated process greatly improves the efficiency and quality of copper recycling.

Feeding

First, scrap copper wires and cables are dropped into the feed opening of the scrap copper wire recycling machine. These scraps can be of various types and sizes, usually including copper cores and insulation materials.

Cutting and crushing

Once the scrap materials enter the machine, they go through a cutting and crushing process. This step is designed to separate the insulating material from the copper core and is usually accomplished through blades, cutting wheels, or other devices within the machine.

Separation

After cutting and crushing, the copper core and the insulation are separated. This is usually accomplished using a vibrating screen, air sorter, or other separating device. The insulating material, which is usually lighter, is separated while the copper core is retained.

Collection and storage

The separated pure copper cores are collected and stored at the output of the machine. These cores are usually high-quality copper and can be used for remanufacturing.

Disposal of insulating materials

The separated insulating materials are usually collected and further processed to treat them as waste or for recycling.

specifications of scrap copper recycling machine

We have different models and colors of copper wire granulator machines and can accept customization. Below are two hot high-output models, you can contact us for more details.

- Model-600

- Capacity: 300-400kg/h

- Power: 42kw

- Weight: 3T

- Size: 4.2*2.2*2.2m

- Model-800

- Capacity: 600-800kg/h

- Power: 59kw

- Weight: 4.5T

- Size: 4.5*2.3*2.2m

- Model-1000

- Capacity: 800-1000kg/h

- Power: 76kw

- Weight: 5.5T

- Size: 7000*2200*2200mm

why choose a copper granulating machine?

The copper wire granulator machine has some features with uniqueness that make it a key piece of equipment in the recycling process of waste copper wires and cables. Some of these features are listed below:

- High-purity separation: achieves separation accuracy exceeding 99%, ensuring copper granules are free of plastic impurities to maximize recycling value.

- High-efficiency processing: integrates crushing, conveying, dust removal, density separation, tailings screening, and intelligent control into a complete automated processing workflow.

- Intelligent operation: equipped with an advanced automatic control system, the entire equipment set requires only one operator, significantly boosting work efficiency and reducing labor costs.

- Flexible adjustability: equipment parameters can be flexibly adjusted according to different types and specifications of scrap wires, ensuring optimal separation results.

- High adaptability: capable of processing various types and specifications of scrap wires and cables, meeting diverse recycling demands with a wide range of applications.

cable wire granulator packing and delivery

The countries to which our machines are usually shipped have extensive metal recycling industries and, therefore, need copper wire granulator machines to process scrap copper wire and cable for efficient recycling and reuse. For example, India, USA, Mexico, Brazil, Spain, Indonesia, UAE, Canada, Australia, and many more.

Our factory also produces other metal recycling-related processing equipment, such as metal shears and industrial shredders, etc. Please feel free to contact us!