تم تصميم جهاز فاصل ACP لفصل الطبقة الألومنيوم تمامًا عن الطبقة البلاستيكية داخل الألواح المركبة من الألومنيوم والبلاستيك، مما يتيح إعادة تدوير فعالة لمواد النفايات المركبة.

باستخدام عملية فصل جافة متقدمة، يقوم الجهاز بتسخين طبقة اللاصق داخل المادة المركبة لإزالة لزوجتها. تلي ذلك عملية فصل ميكانيكية، تضمن فصل الألمنيوم والبلاستيك بشكل كامل ودون تلف. العملية بأكملها خالية من الدخان، وخالية من الماء، وخالية من التلوث، مما يجعلها صديقة للبيئة وموفرة للطاقة، بالإضافة إلى تعظيم احتفاظ المادة بخصائصها الأصلية.

مع التخلّص بعزل يصل إلى 99% وبقدرة معالجة يومية من 2-6 أطنان، يُستخدم جهاز فاصل ACP على نطاق واسع في مختلف قطاعات إعادة تدوير النفايات البولي-الألومنيوم، محققًا فوائد اقتصادية واجتماعية كبيرة للمؤسسات.

تتميز آلات الفصل ACP بأنها متعددة الاستخدامات ويمكن استخدامها ليس فقط لإعادة تدوير مركبات الألومنيوم والبلاستيك ولكن أيضًا لفصل ومعالجة المواد الأخرى المشابهة. إنهم يلعبون دورًا حاسمًا في مختلف القطاعات، بما في ذلك التصنيع وحماية البيئة.

احتمال إعادة تدوير ألواح الألمنيوم المركبة ACP

يشتهر الألومنيوم بقابلية إعادة التدوير الممتازة وقيمة الخردة العالية. تنتج عملية تصنيع ألواح الألمنيوم المركبة كمية كبيرة من الخردة التي تحتاج إلى إعادة تدويرها.

حاليًا، تبلغ تكلفة المواد اللازمة لألواح الألومنيوم المركبة (ACP) حوالي $17.36 للمتر المربع. في المقابل، يبلغ متوسط سعر السوق للألمنيوم المنفصل حوالي $2,811 للطن، في حين يقدر سعر البلاستيك بحوالي $1,079 للطن.

يشير هذا إلى أن تشغيل آلة فصل ACP يمكن أن يكون مشروعًا منخفض التكلفة ومرتفع الربح. بمجرد تحديد نوع المادة الخام والإنتاج الذي تريده، يمكننا مساعدتك في تقييم أرباحك المحتملة.

مجالات التطبيق لآلة الفصل ACP

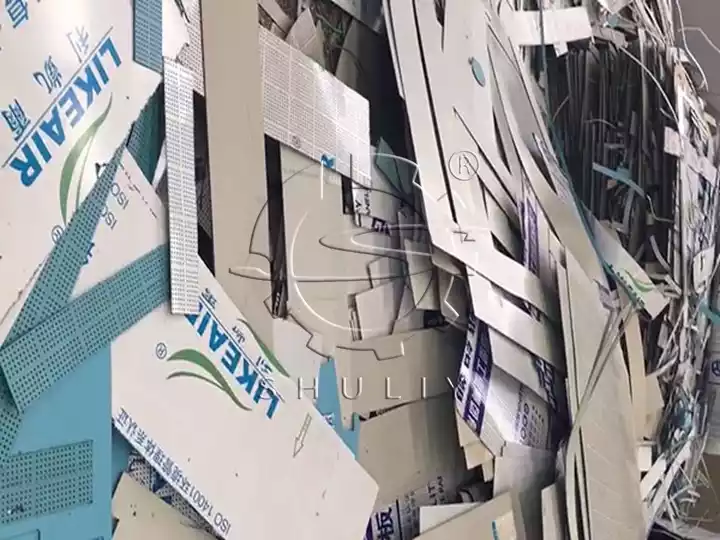

هذه المعدات مصممة بشكل رئيسي لمعالجة مختلف مخلفات المواد المركبة الألومنيوم-البلاستيك والمواد المشابهة، بما في ذلك على سبيل المثال لا الحصر:

- ألواح مركبة من الألومنيوم والبلاستيك، صفائح مركبة من الألومنيوم والبلاستيك خردة، أنابيب مركبة من الألومنيوم والبلاستيك، شظايا مركبة من الألومنيوم والبلاستيك.

- أنابيب معجون الأسنان، أغطية العبوات الدوائية (صفائح الكبسولات)، فيلم ألومنيوم-بلاستيكي من عبوات الأدوية.

- أكياس تغليف غذائية من ورق ألومنيوم، أغطية الزبادي، أكياس الحليب، أشرطة إغلاق أغطية الزجاجات، إلخ.

- دوائر مطبوعة تحتوي على الألومنيوم، مواد تعبئة بلاستيكية-ألومنيوم، إلخ.

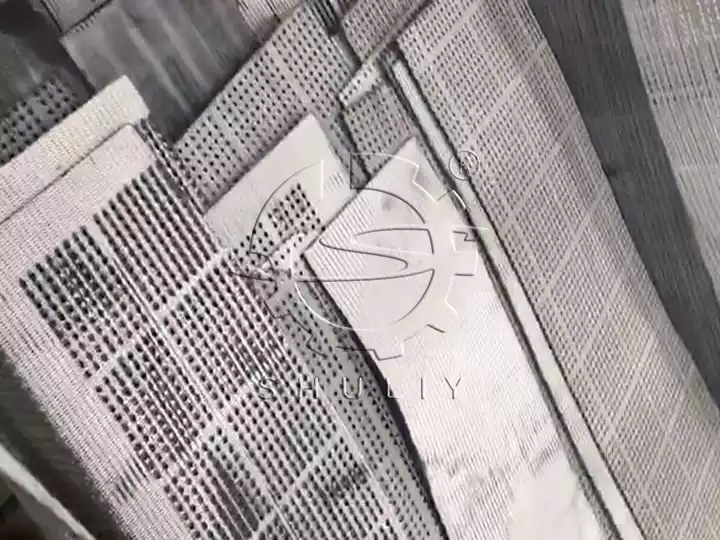

يمكن صهر الألومنيوم المفصول مباشرةً إلى سبائك ألمنيوم أو إعادة معالجته إلى مسحوق الألومنيوم، منتجات الألومنيوم، إلخ. يمكن إعادة تدوير المكونات البلاستيكية إلى صفائح بلاستيكية، أنابيب، منتجات تعبئة، إلخ، محققة دورات الموارد وتحويل النفايات إلى كنز.

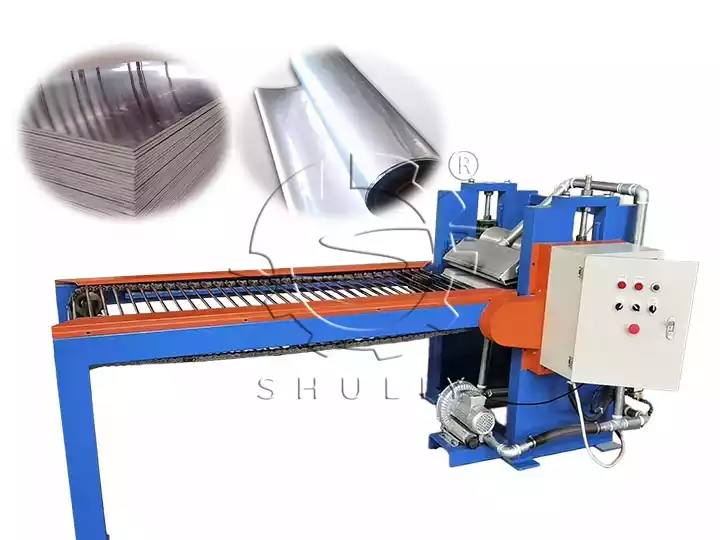

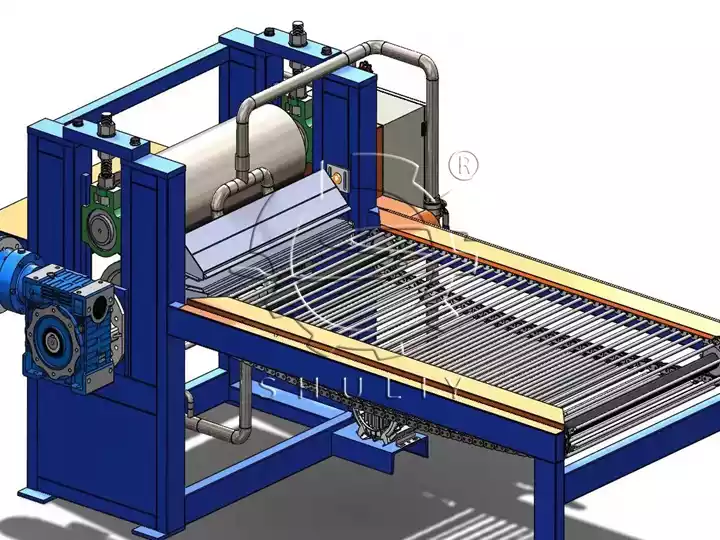

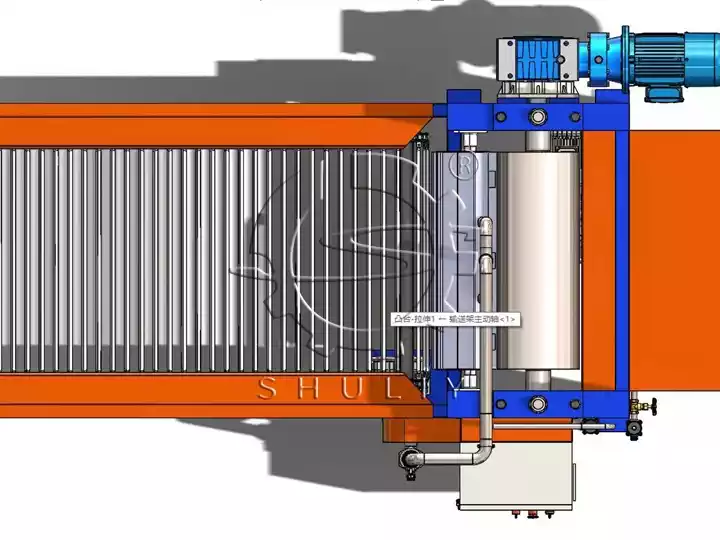

آلة فصل التسخين للوحة ACP الهيكل الرئيسي

تتكون آلة الفصل ACP من عدة مكونات، بما في ذلك آلية التجريد، وآلية التفريغ، والأسطوانة، والعجلة المسننة، وآلية الطاقة.

تتميز آلية الطاقة بمحرك وعلبة تروس، مع توصيل مخرج المحرك بمدخل علبة التروس عبر الحزام. يضمن هذا التصميم أن تكون الماكينة سليمة من الناحية الهيكلية وتعمل بسلاسة.

كيف تعمل آلة تجريد Scrap ACP؟

يعمل فاصل المواد من الألواح البلاستيكية المركبة المصنوعة من الألومنيوم والبلاستيك باستخدام تقنية الفصل الفيزيائي الجاف، مما يتطلب تسخين الماكينة إلى درجة حرارة معينة. ومن خلال الاستفادة من الخصائص الفيزيائية المختلفة للألمنيوم والبلاستيك، يتم فصل المواد بكفاءة ونقاء بعد خضوعها لعمليات التكسير والتمزيق والفصل.

آلة تجريد ألواح الألمنيوم المركبة في مصنعنا تستخدم طريقتين للتسخين: اللهب المكشوف باستخدام الغاز المسال أو التسخين الكهربائي الأوتوماتيكي. تعمل هذه العملية على تنعيم سطح لوح الألومنيوم المركب، مما يسمح بفصل طبقة الألومنيوم عن الطبقة البلاستيكية، والتي يمكن بعد ذلك تمزيقها يدويًا.

ميزات آلة إعادة تدوير ألواح الألمنيوم المركبة

- كفاءة فصل عالية: باستخدام تقنية التسخين والفصل الجاف المتقدمة، يصل معدل فصل الألومنيوم-البلاستيك إلى 99%. الناتج المنقى جاهز للبيع مباشرة.

- موفر للطاقة وصديق للبيئة: تشغيل خالٍ تمامًا من الدخان، وخالٍ من الماء، وخالٍ من الانبعاثات. لا حاجة إلى إضافات كيميائية، متوافق تمامًا مع المعايير البيئية.

- استهلاك طاقة منخفض وضجيج منخفض: قدرة المحرك الرئيسية فقط 2.2 كيلوفاط، يضمن تشغيلًا مستقرًا، وضجيجًا محدودًا، وتكاليف صيانة منخفضة.

- هيكل مدمج، مساحة أساسية صغيرة: تصميم مدمج مع أبعاد صغيرة وتركيب سهل، مثالي لاستثمار من قبل مؤسسات إعادة تدوير صغيرة ومتوسطة.

- عائد سريع على الاستثمار: انخفاض استثمار المعدات، كفاءة عالية، ودورات تدوير قصيرة تتيح توليد عوائد اقتصادية بسرعة.

- تنوّع عالي: قادر على معالجة ليس فقط الألواح المركبة من الألومنيوم والبلاستيك بل أيضًا فصل مواد مركبة تحتوي على الألومنيوم، مما يتيح إمكانات سوقية كبيرة.

المعلمات التقنية لآلة تجريد صفائح ACP

الجهد القياسي لآلة فاصل ACP لدينا هو 380 فولت/50 هرتز. بالإضافة إلى ذلك ، نقدم خيارات التخصيص للجهد والحجم والقدرة والمتطلبات المحددة الأخرى. إذا كنت مهتمًا ، فيرجى عدم التردد في الاتصال بنا.

| نموذج | فاصل SL-600 | SL-800 فاصل | SL-1000 فاصل |

| عرض العمل | 400 ملم | 600 ملم | 800mm |

| ملائم | جميع أنواع المواد ACP | جميع أنواع المواد ACP | جميع أنواع المواد ACP |

| الحجم (الطول * العرض * الارتفاع) | 1400 مم * 1500 مم * 1100 مم | 3900mm* 2300mm* 1100mm | 3900mm* 2500mm* 1100mm |

| وزن | 800 كلغ | 1200 كجم | 1300 كجم |

| الجهد االكهربى | 380 فولت /2.2 كيلو واط 50 هرتز /3 مرحلة (يمكن تخصيص المحرك) | 380 فولت /4 كيلوواط 50 هرتز /3 مرحلة (يمكن تخصيص المحرك) | 380 فولت /4 كيلوواط 50 هرتز /3 مرحلة (يمكن تخصيص المحرك) |

| سعة | 4 طن / 8 ساعات | 4 طن / 8 ساعات | 4 طن / 8 ساعات |

| استهلاك الغاز | 2.5 كجم/ساعة | 3.75 كجم/ساعة | 4 كجم/ساعة |

لقد شاركت مصنعنا في صناعة إعادة تدوير المعادن لسنوات عديدة، بجانب هذه الآلة نحن أيضاً ننتج آلة إعادة تدوير جرانولات أسلاك النحاس. ندعوك بصدق للتواصل معنا بنشاط. مع دعمنا الفني الاحترافي وأكثر من 20 عامًا من الخبرة في الصناعة، نعتقد أننا يمكن أن نقدم ضمانًا قويًا لعملك في إعادة تدوير الألمنيوم. يمكنك ترك رسالة لنا مباشرة من خلال النموذج على اليمين، وسنرد عليك في أقرب وقت ممكن!