The ACP separator machine is designed to completely separate the aluminum layer from the plastic layer within aluminum composite panels (ACP), enabling efficient recycling of waste aluminum composite materials.

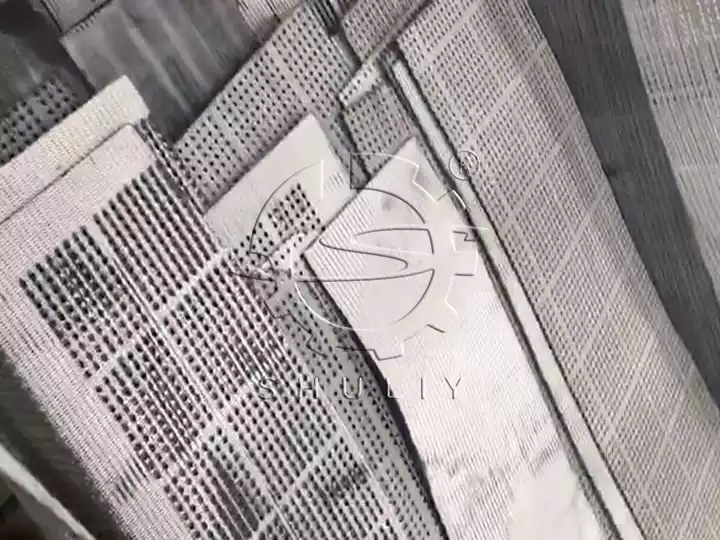

Employing an advanced dry physical separation process, the machine heats the adhesive layer within the composite material to eliminate its tackiness. This is followed by mechanical separation, ensuring the aluminum and plastic are completely and undamagedly separated. The entire process is smoke-free, waterless, and pollution-free, making it not only environmentally friendly and energy-efficient but also maximizing the retention of the material’s original properties.

Boasting a separation rate of up to 99% and a daily processing capacity of 2-6 tons, the ACP separator machine is widely applied in various aluminum-plastic waste recycling sectors, delivering substantial economic and social benefits to enterprises.

ACP separator machines are versatile and can be used not only for recycling aluminum-plastic composites but also for separating and processing other similar materials. They play a crucial role in various sectors, including manufacturing and environmental protection.

Prospect of aluminum composite panel ACP recycling

Aluminum is known for its excellent recyclability and high scrap value. The manufacturing process of aluminum composite panels produces a significant amount of scrap that needs to be recycled.

Currently, the cost of materials for aluminum composite panels (ACP) is around $17.36 per square meter. In contrast, the average market price for separated aluminum is approximately $2,811 per tonne, while plastic is valued at about $1,079 per tonne.

This indicates that running an ACP separator machine could be a low-cost, high-profit venture. Once you identify the type of raw material and the output you want, we can assist you in evaluating your potential profits.

Areas of application for the ACP separator machine

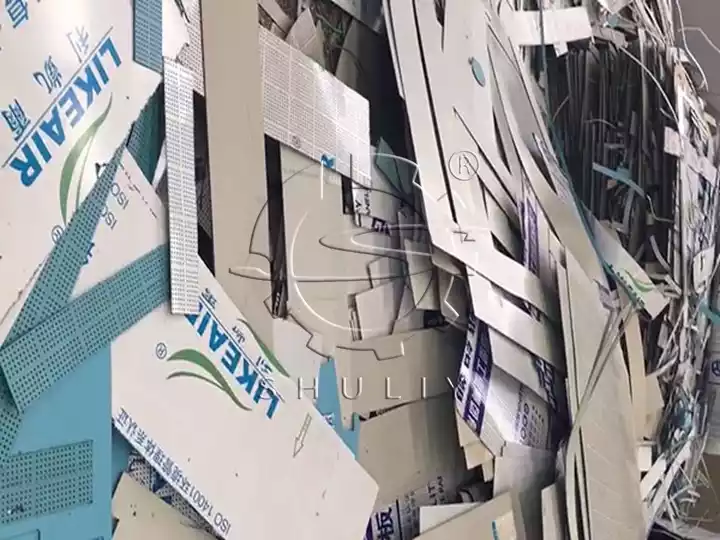

This equipment is primarily designed for processing various aluminum-plastic composite waste materials and similar substances, including but not limited to:

- Aluminum-plastic composite panels, scrap aluminum-plastic composite sheets, aluminum-plastic pipes, aluminum-plastic fragments.

- Toothpaste tubes, pharmaceutical blister packs (capsule boards), aluminum-plastic film from medicine blister packs.

- aluminum foil food packaging bags, yogurt lids, milk pouches, bottle cap sealing films, etc.

- aluminum-containing circuit boards, plastic-aluminum packaging materials, etc.

The separated aluminum can be directly remelted into aluminum ingots or reprocessed into aluminum powder, aluminum products, etc. The plastic components can be recycled into plastic sheets, pipes, packaging products, etc., achieving resource circulation and turning waste into treasure.

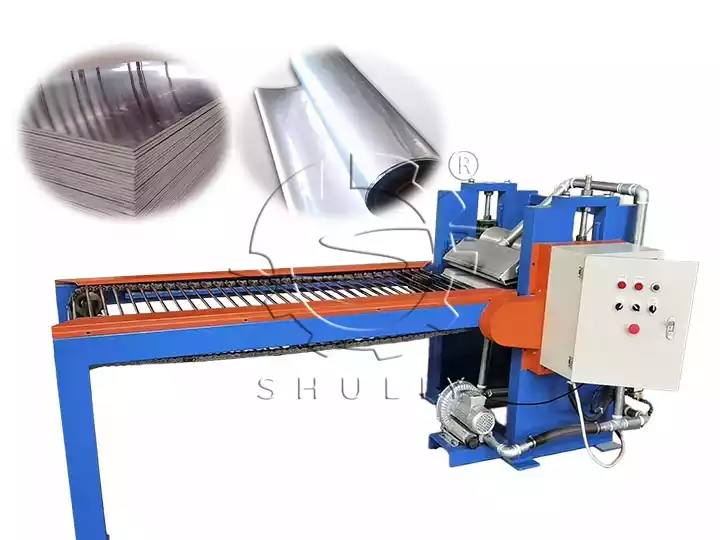

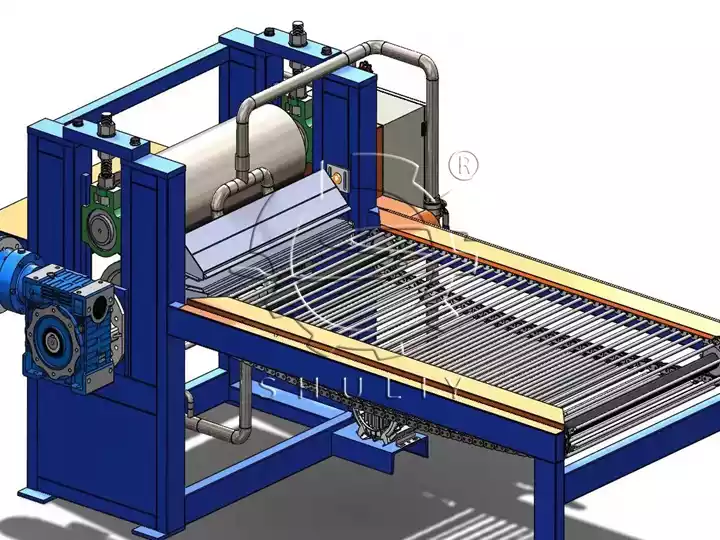

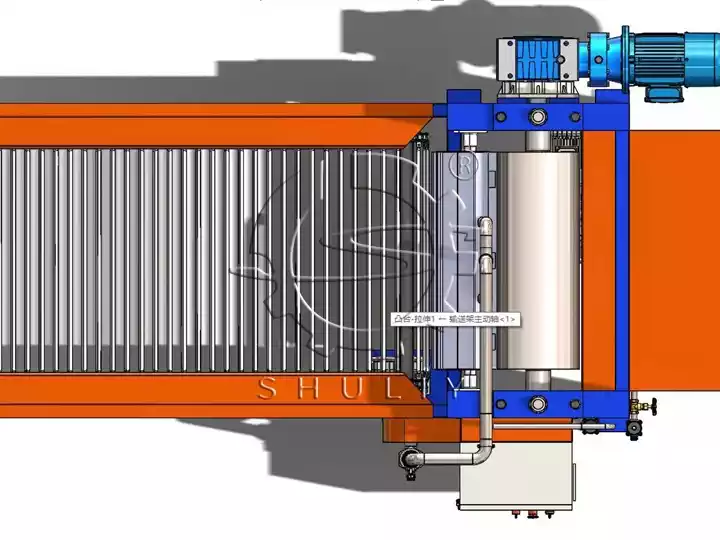

ACP Board Heating Separating Machine Main structure

The ACP separator machine consists of several components, including a stripping mechanism, a discharging mechanism, a roller, a sprocket, and a power mechanism.

The power mechanism features a motor and a gearbox, with the motor’s output connected to the gearbox’s input via a belt. This design ensures that the machine is structurally sound and operates smoothly.

How does the Scrap ACP stripping machine work?

The aluminum plastic composite panel material separator operates using dry physical separation technology, requiring the machine to be heated to a specific temperature. By leveraging the differing physical properties of aluminum and plastic, the materials are efficiently and purely separated after undergoing processes of crushing, tearing, and separating.

Our factory’s aluminum composite panel stripping machine utilizes two methods for heating: an open flame using liquefied gas or automatic electric heating. This process softens the surface of the Aluminum Composite Panel, allowing for the separation of the aluminum layer from the plastic layer, which can then be manually torn off.

Aluminum Composite Panels Recycling Machine Features

- High separation efficiency: utilizing advanced heating and dry separation technology, achieving up to 99% aluminum-plastic separation rate. The purified output is ready for direct sale.

- Energy-efficient and eco-friendly: entirely smoke-free, waterless, and emission-free operation. No chemical additives required, fully compliant with environmental standards.

- Low energy consumption & low noise: main motor power is only 2.2kW. Ensures stable operation, minimal noise, and low maintenance costs.

- Compact structure, minimal footprint: integrated design with small dimensions and easy installation, ideal for investment by small and medium-sized recycling enterprises.

- Rapid return on investment: low equipment investment, high efficiency, and short recycling cycles enable swift generation of economic returns.

- High versatility: capable of processing not only aluminum-plastic composite panels but also separating various aluminum-containing composite materials, offering significant market potential.

ACP sheet stripping machine technical parameters

The standard voltage for our ACP separator machine is 380V/50HZ. Additionally, we offer customization options for voltage, size, capacity, and other specific requirements. If you’re interested, please don’t hesitate to contact us.

| Model | SL-600 separator | SL-800 separator | SL-1000 separator |

| Working width | 400mm | 600mm | 800mm |

| Applicable | All kinds of ACP material | All kinds of ACP material | All kinds of ACP material |

| Size( L*W*H ) | 1400mm* 1500mm* 1100mm | 3900mm* 2300mm* 1100mm | 3900mm* 2500mm* 1100mm |

| Weight | 800kgs | 1200kgs | 1300kgs |

| Voltage | 380V/2.2 KW 50HZ /3 phase (motor can be customized) | 380V/4 KW 50HZ /3 phase (motor can be customized) | 380V/4 KW 50HZ /3 phase (motor can be customized) |

| Capacity | 4t/8 hours | 4t/8 hours | 4t/8 hours |

| gas consumption | 2.5kg/h | 3.75kg/h | 4kg/h |

Our factory has been engaged in the metal recycling industry for many years, besides this machine we also produce copper wire granulator recycling machine. We sincerely invite you to actively consult with us. With our professional technical support and more than 20 years of industry experience, we believe we can provide a strong guarantee for your aluminum recycling business. You can leave us a message directly through the form on the right, and we will reply to you as soon as possible!