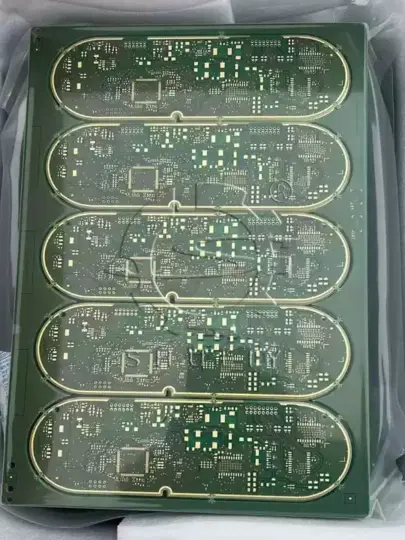

Waste circuit boards typically contain multiple metals such as copper, aluminum, and iron, along with polymer resin materials, with metal content exceeding 30%. Achieving efficient, environmentally friendly, and automated separation has become a key focus in the electronic waste recycling industry.

This PCB circuit boards crusher and separator recycling production line integrates shredding, crushing, sorting, and dust removal. It employs a PLC intelligent control system combined with multi-stage physical sorting technology to achieve efficient separation of metals and non-metals from waste circuit boards.

The entire line achieves a metal recovery rate of 98%–99% or higher, with dust removal efficiency exceeding 99%, effectively reducing dust pollution. With configurable models, production capacity ranges from 150kg/h to 1200kg/h, making it suitable for small-to-medium recycling enterprises and large-scale processing plants.

Through a multi-stage process—shredding + crushing + water-cooled pulverization + airflow separation + electrostatic separation—this line achieves precise separation of copper powder and resin powder. Offering high sorting purity and stable operation, it stands as one of the most mature equipment solutions in the field of electronic waste resource utilization.

applications of PCB recycling production line

This circuit boards crusher and separator recycling line is suitable for recycling and processing various types of electronic waste and scrap materials, including but not limited to:

- Scrap computer motherboards, television circuit boards, and power supply boards

- Circuit boards from various communication devices

- Copper-clad laminate (CCL)

- PCB circuit board scrap

- Boards from dismantled electronic components

- Mixed resin boards containing metal powders

Suitable not only for professional electronic waste recycling enterprises, but also for use by metal smelters, resource recovery companies, and environmental technology enterprises.

circuit boards crusher and separator unit features

Intelligent Automated Control System

The entire line employs a PLC-programmed automated control system equipped with a human-machine interface touchscreen. This enables centralized control, real-time monitoring, and parameter adjustment, ensuring user-friendly operation and reducing labor costs.

Multi-Stage Combined Crushing System

Features a multi-stage crushing structure comprising a shredder + hammer crusher + water-cooled grinding mill. This achieves more uniform material particle size, ensuring reliable high-precision sorting in subsequent processes.

Circulating Water-Cooling Design

A circulating water-cooling system is integrated both inside and outside the grinding chamber. This effectively controls equipment temperature rise, prevents resin melting and adhesion caused by high temperatures, and enhances separation efficiency and equipment lifespan.

Efficiency Environmental Dust Collection System

Configured with a negative pressure feeding system and pulse-jet dust collector, achieving over 99% dust removal efficiency. This significantly improves the working environment and meets environmental emission standards.

High-Precision Sorting Technology

Combines airflow density separation with electrostatic separation for thorough separation of metal and non-metal powders, achieving metal recovery rates exceeding 99%.

Compact Structure and Rational Layout

Optimized circuit boards crusher and separator line design ensures efficient space utilization, stable operation, and easy maintenance, making it ideal for large-scale continuous production.

PCB crushing and sorting line Processing Flow

The raw material for this production line consists of circuit boards dismantled by PCB electronic component dismantling machines.

The overall process flow of this printed circuit boards crusher and separator recycling production line is as follows:

- Feeding system: waste circuit boards enter the shredder via the conveyor system.

- Shredding (Shredder): initial crushing of large circuit board pieces.

- Hammer crusher: further reduction of material into smaller particles.

- Water-cooled milling: fine grinding is performed via a water-cooled circulation system, with particle size controlled by a rotary screen.

- Air separator: preliminary separation of metals and non-metals is achieved using density differences.

- Electrostatic sorting machine: achieves high-precision separation of metal and resin powders based on differences in conductivity.

- Dust removal system: maintains negative pressure dust extraction throughout the process to ensure environmentally compliant production.

Final Output:

- Metal powder

- Non-metallic powder (resin powder)

waste circuit boards recycling machine parameters

| Model | Power | Recovery Percent | Collection Coefficient | Output (kg/h) | External Dimension (mm) | Weight (kg) |

| SL-1000 | 45kw | ≥98% | ≥99% | 150–200 | 6000×7500×4200 | 4250 |

| SL-1500 | 68kw | ≥98% | ≥99% | 200–300 | 7000×8200×4500 | 6500 |

| SL-1800 | 110kw | ≥98% | ≥99% | 300–500 | 8000×11000×4800 | 8500 |

| SL-2000 | 198kw | ≥98% | ≥99% | 1000–1200 | 8200×16000×5250 | 12500 |

If you’re looking for a PCB recycling solution with high recovery rates, strict environmental standards, and advanced automation, this production line is a strong choice for resource reuse and profitability. Contact us today for detailed solutions and customized configuration recommendations.