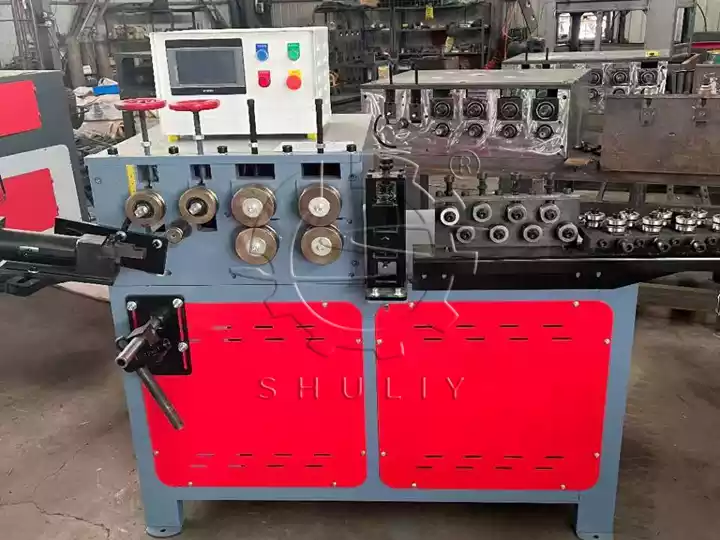

The CNC spring coiling machines have become core equipment in the spring manufacturing industry due to their high precision, efficiency, and intelligent control. Across automotive, electronics, hardware, and home appliance sectors, demands for spring performance and accuracy continue to rise, with material selection being the key determinant of quality.

Capable of processing various metal materials

CNC spring machines utilize advanced servo drives and numerical control systems to adapt flexibly to diverse spring materials, ensuring high forming precision and consistency. Commonly processed materials include:

- Stainless steel wire (SUS304, SUS316, etc.): exceptional corrosion resistance, widely used in medical, electronic, and food machinery applications.

- Carbon steel wire (SWC, SWP-A/B): high strength and low cost, suitable for mass production of automotive suspension springs and industrial springs.

- Phosphor bronze and brass wire: excellent conductivity and stable elasticity, commonly used in electronic contacts and precision instruments.

- Alloy steel wire (60Si2MnA, 55CrSi): features outstanding fatigue strength and wear resistance, suitable for springs subjected to high loads or high-frequency operation.

This multi-material compatibility enables CNC spring coiling machines to meet diverse production demands across various industries.

Intelligent CNC Spring coiling Machines

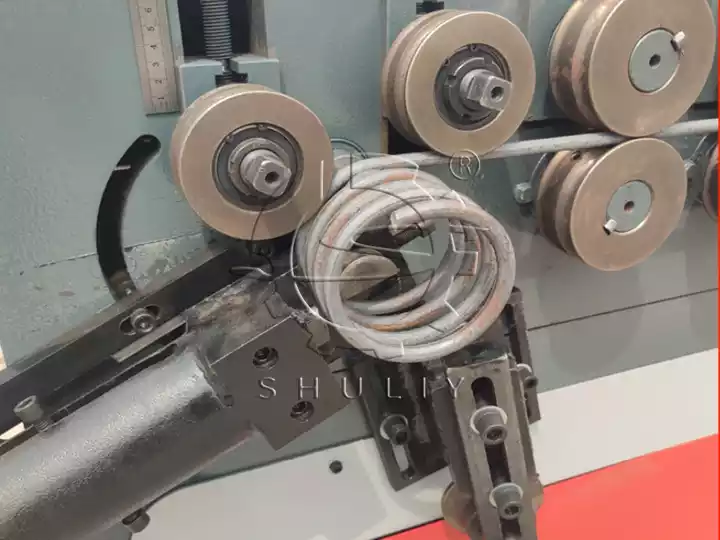

CNC spring machines utilize multi-axis linkage and real-time servo adjustment technology to precisely control wire diameter, coil pitch, angle, and pitch.

- Automatic compensation system: continuously monitors material elasticity changes and automatically adjusts parameters to ensure consistency in every spring.

- Graphical programming interface: enables rapid product model switching without complex operations, significantly boosting production efficiency.

- High-precision sensor inspection: ensures each spring is dimensionally accurate, burr-free, and deviation-free.

Intelligent control not only enhances processing stability but also saves enterprises setup time and labor costs.

Balancing Efficiency and Quality

Compared to traditional mechanical equipment, CNC spring machines offer superior automation and energy efficiency:

- High-speed operation and continuous production: supports prolonged stable operation, boosting output per unit.

- Low-energy design: servo systems precisely regulate power output, reducing production costs.

- Reduced scrap rates: precise forming minimizes material waste, enabling green production.

By adopting CNC spring machines, enterprises not only achieve high-quality products but also elevate overall production efficiency and market competitiveness.

conclusion

The multi-material processing capabilities and intelligent control technology of CNC spring coiling machines open broader application possibilities for manufacturing enterprises.

Whether pursuing high precision, high efficiency, or achieving diversified product production, selecting an advanced CNC spring machine is a crucial step toward smart manufacturing. If you have any questions, please don’t hesitate to contact us at your convenience.