In the middle of this month, our company successfully manufactured and exported two plastic granulating machines and one plastic crusher to Tanzania to help a local plastic pipe manufacturer realize the recycling of waste plastics and save costs.

Customer Background and Needs

This Tanzanian customer is a plastic pipe manufacturer whose main business includes the production and sale of various types of plastic pipes.

With the expansion of production scale, the customer is facing the problem of the high cost of plastic raw materials and disposal of waste plastics. Therefore, the customer decided to purchase a plastic pelletizer to convert waste plastics into usable raw materials.

To learn more about the machine click Plastic Pelletizing Machine PP PE Granule Extruder For Sale.

Detailed information on plastic granulating machines

After detailed communication with our business manager, the customer learned how to use the plastic granulator. The business manager also suggested the customer buy a plastic crusher for the preliminary crushing of waste plastics.

The customer finally decided to buy one plastic crusher and two plastic granulators with the same model but different parameters. This can better meet their demand for raw materials of different sizes of plastic pipes.

The output of the plastic crusher is 500-600kg/h with 10 internal blades made of 60Si2Mn.

Host plastic pellets making machine

- Model: SL- 150

- Power: 37kw

- 500 reducer, 2m screw

- Electromagnetic heating

Second pellet making machine

- Model: SL- 150

- Power: 15kw

- 400reducer, 1m screw

- Heating ring

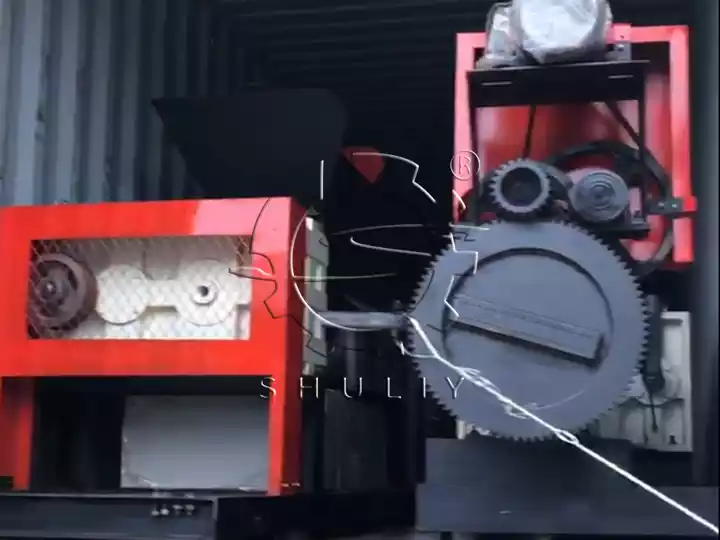

Packing and shipping site

After the plastic granulating machines were manufactured, we carried out strict quality inspection on the equipment to ensure that each machine could run stably.

After that, our professional packaging team packed the machines properly, using shockproof and moisture-proof materials to reinforce the machines to ensure that they would not be damaged during long-distance transportation.

On the day of shipment, the staff loaded the machine in the warehouse and kept a detailed record of each step. Once the packaging was completed, the machines were safely loaded onto the truck and shipped to the port. This batch of equipment will arrive in Tanzania soon to help the local customer’s production operation.