The industrial shredder machine, also known as the universal shredder, is a multi-functional shredding equipment used to process all kinds of waste materials. With strong shredding capacity and suitable for a variety of materials, it is widely used in waste treatment, recycling, and other fields.

What can an industrial shredder machine shred

In general, the universal shredder is designed to be suitable for shredding and processing a wide range of materials to achieve waste minimization and resource reuse. The following are some common types of materials:

- Plastics: e.g. plastic bottles, plastic buckets, plastic films, plastic pipes, etc.

- Wood: Wooden boards, wooden strips, wooden boxes, etc.

- Paper: cartons, cardboard, books, documents, etc.

- Metal: Iron sheets, aluminum cans, scrap metal parts, etc.

- Rubber: Rubber products, waste tires, etc.

- Textiles: Waste clothing, bedding, etc.

- Electronic Waste: Waste electronic products, wires and cables, etc.

- Life Waste: Kitchen waste, discarded food packaging, etc.

- Medical Waste: Waste of some medical supplies.

- Glass: glass bottles, glassware, etc.

How the shredding machine works

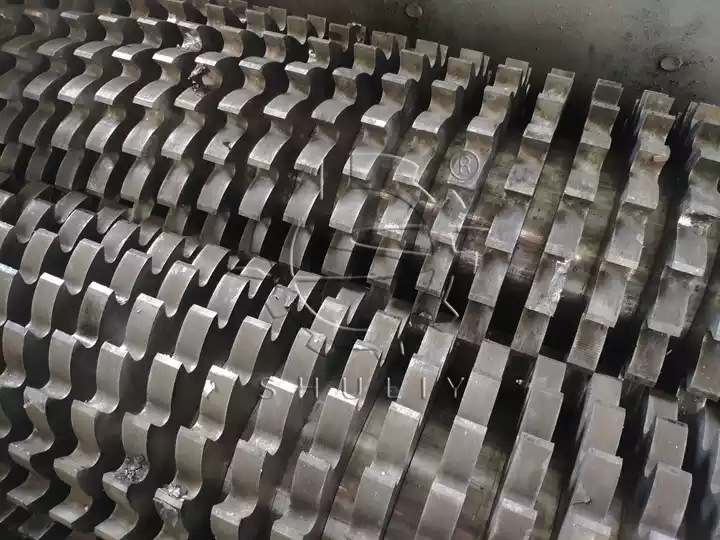

- The general industrial shredder machine has two axes, and the working principle is basically to tear and cut the materials through two interlocking rotating axes, which are equipped with blades or knives.

- In this case, the two shafts rotate in opposite directions and the blades form a tearing space between the two shafts, thus shredding the material into smaller pieces or flakes.

- This design can effectively cope with materials of various hardnesses and shapes, providing efficient shredding performance, and is widely used in areas such as waste processing and treatment recycling.

Different models and specifications of universal shredders may have better applicability to different types of materials, and you should make choices based on specific processing needs. Feel free to contact us to help you choose the most suitable machine.