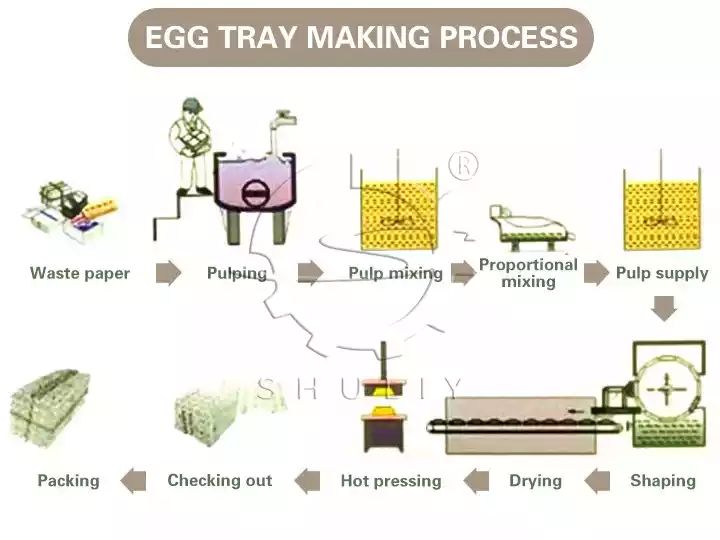

The egg tray molding machine is a kind of special equipment used to produce egg cartons, and its production process involves raw material preparation, molding, drying, packaging, and so on. This article will introduce the process and principle of pulp molding egg tray-making production equipment in detail.

raw material preparation

The main raw materials for the egg tray molding machine are waste paper and water, in the production process, you need to shred the waste paper and mix it with water to make pulp.

egg tray molding machines

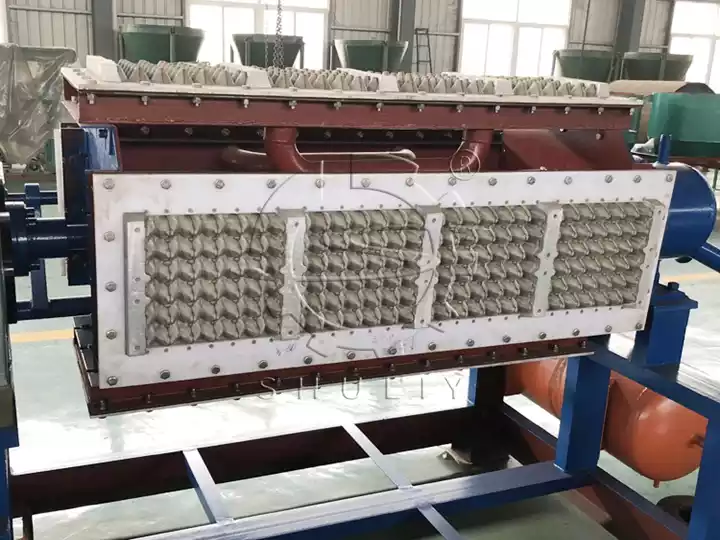

Molding is the core link of egg crate production equipment, its principle is to inject pulp into the molding die, after a series of operations, to form egg trays with corresponding shapes and sizes.

Forming mold preparation

Forming molds are made of metal materials with certain strength and wear resistance, and their production needs to be designed and processed according to the specifications and sizes of the egg trays.

Pulp injection and rapid draining

The made pulp is poured into the injection port and injected evenly into the forming mold by controlling the flow rate of pulp and pulp temperature. Then the pulp is molded by rapid vibration of the mold or giving a certain pressure to accelerate the removal of water.

Demolding

After the egg tray is molded, the mold is sent into the demolding machine, and the molded egg tray is taken out from the mold by means of a motion device suction cup, etc. to form the finished product.

egg carton drying process

- After the egg tray is molded, it still needs to pass through the drying process, which uses hot air to heat and evaporate, so that it loses excess water and enhances the hardness and stability of the product.

- After drying, the temperature of the egg carton needs to be lowered by external natural cooling or through the cooling system. Then the egg tray is checked for quality to ensure that it meets the production requirements and is classified and graded.

It should be noted that the brick kiln drying is the customer’s own local construction, we can according to the customer site and egg tray production line configuration design drawings.

egg crate packaging and hot press

- After the production of the egg tray is completed, it needs to be properly packaged for transportation and sales.

- In addition, depending on your needs, adding a heat press is your finished product surface is smoother and more delicate, more beautiful to sell better.

In summary, the production process of egg tray molding machines is not complicated. Through reasonable operation and control, efficient, stable, and high-quality egg tray production can be realized. If you want to know more information about the machine, please feel free to contact us.