The rigid plastic pelletizing line is used to process and recycle used or discarded materials into pelletized plastics for the remanufacture of plastic products. These materials include high-density polyethylene (HDPE), polypropylene (PP), polystyrene (PS), and other rigid plastics.

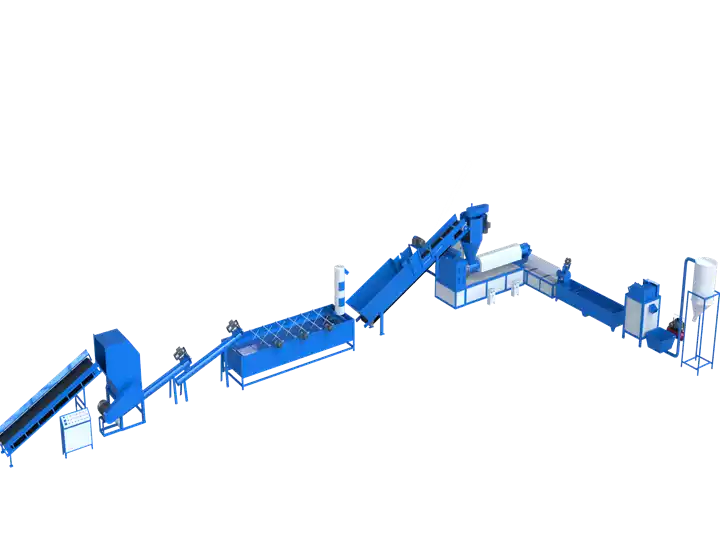

This PP PE rigid plastic pelletizing line typically includes crushing, washing, melting, and pelletizing. The output is 200-2000kg/h. According to your different production needs, usage, raw materials, plant design, and area. We can customize the plastic recycling production line with different scales and configurations.

Processable raw materials

Rigid plastic pelletizing lines are generally capable of processing all rigid plastics. These plastics typically include bottles, buckets, water pipes, furniture items, food containers, automotive parts, food packaging, plastic cutlery, appliance housings, and more.

final pellets product

These pellets obtained are widely used. They can be used in the production of new plastic bottles, packaging materials, pipes, household goods, and construction materials.

rigid plastic pelletizing line workflow

To realize the reuse and recycling of waste hard plastics, a series of processes are required, including raw material collection and sorting → de-labeling → crushing → washing → dehydration → granulation → cooling → packaging.

machines for plastic recycling plant

Crusher Machine: used plastic products are pulverized into chips to provide feedstock for subsequent processing steps.

Advantages include increased disposability of waste plastics, reduced volume, reduced transportation costs, and facilitated recycling of plastics.

Plastic Washer: physically and chemically removes impurities, dirt, and contaminants from used plastics to improve quality and reusability. Provides clean plastic chips for pelletizing operations.

Dewatering Machine: the high-speed rotation can quickly remove excess water from the surface of waste plastics, reduce humidity, improve the quality of recycled materials, and reduce material loss.

Automatic Feeder: feed clean raw materials into the granulator evenly and efficiently to ensure a continuous and stable supply of raw materials. Reduces the need for manual labor, reduces material waste, and improves production efficiency.

Plastic Pelletizer: processing of cleaned plastic chips into pellets for reuse. Benefits include increased reuse of waste plastics, reduced resource waste, lower environmental burden, and cost savings.

Pellet Cutting Machine: cut long pellets produced by a pelletizer to the desired length to meet specific production requirements. Benefits include providing more flexible pellet length options, reducing waste, and increasing production efficiency.

pellet making machine in plastic recycling line

- The plastic pelletizer is the most central piece of equipment in a hard rigid plastic pelletizing line.

- This machine is responsible for melting, extruding, shearing, and cooling pieces of hard plastic into uniform, granular recycled plastic pellets.

- These machines can often be adapted to different types of hard plastics and pellet specifications to meet the needs of different customers.

Production line supporting equipment

In the rigid plastic pelletizing line, there is also a need for some conveying equipment to connect the various machines, such as loaders, screw conveyors, and belt climbing conveyors.

There are also exhaust fume purifiers, cooling tanks, and storage bins to be used in conjunction. Finally, you can also choose a bagging machine for packaging the finished products for easy storage and sale.

plastic recycling granulating line successful cases

Plastic Crushing Washing Granulating Recycling Lines have gained wide popularity across the globe. Some of the popular countries include Oman, the United States of America, Japan, Germany, the United Kingdom, France, Italy, Canada, Australia, the Netherlands, Singapore, and South Korea, among others.

Our client operates a business in Saudi Arabia that uses a lot of plastic packaging materials. They reduce packaging costs and minimize waste by recycling and reusing plastic packaging waste. Recently, they purchased a rigid plastic pelletizing line from our company and successfully put it into operation. We are now showing their feedback video at the work site, demonstrating the efficient operation of the equipment and excellent recycling results.

If you want to deal with soft plastic film, you can choose our Plastic Film Pelletizing Line For PP PE Granulating Recycling Plant.

why choose shuliy machines?

There are two main reasons why our company’s rigid plastic pelletizing line is so popular, one is the excellent service and the other is the competitive price.

- First of all, we focus on providing customers with a full range of services, including pre-sales consultation, equipment selection, site layout planning, installation and commissioning, training, and so on. Our professional team has rich technical experience and can provide customized solutions to meet different needs.

- Secondly, we do our best to ensure competitive prices. We understand the importance of price to our customers, so we have been continuously optimizing costs, improving productivity, and providing high-quality equipment at the most competitive prices.

We provide a one-stop solution for plastic recycling

In addition to providing efficient and environmentally friendly equipment, we can also provide additional supporting services for our plastic washing and recycling machines. Such as designing your workshop; recycling wastewater from the plastic washing line; how to sharpen the knives after the crusher has been used for some time; how to choose a chiller or cooling tower for your plastic granulator. As well as how to excavate the drainage ditch, and how to arrange the wires and span structure after the machine arrives at the customer’s factory. We can all communicate and guide according to customers’ requirements.