In the field of plastic bottle recycling, label removal is a critical step in ensuring high-quality recycled PET plastic. The PET plastic bottle label removing machine is specifically designed for quick and efficient removal of labels from bottle bodies. It achieves a label removal rate of over 98% while maintaining a bottle body damage rate of less than 5%.

This equipment features a robust structure and stable performance, with a service life capable of processing over 10,000 tons of raw material, making it an indispensable pre-processing unit in PET bottle recycling production lines. Labels removed from the bottles can be directly fed into the crushing and washing processes, significantly enhancing the purity and economic value of recycled PET flakes.

label removing machine applications

PET label removal machines are widely used in various industries that require the removal of labels from bottle surfaces, primarily including:

- Plastic recycling industry: used to remove labels from PET, PP, and other types of bottle containers, providing clean raw materials for subsequent crushing and cleaning processes.

- Food and beverage industry: removing labels before processing recycled bottles or repackaged products to prevent cross-contamination.

- Pharmaceutical and chemical industry: ensuring safety and cleanliness during container reuse or recycling processes.

- Retail and logistics sector: rapidly removing labels from returned goods or relabeled products to improve operational efficiency.

Whether dealing with plastic, glass, or metal containers, label removing machines can efficiently adapt to different materials and bottle shapes, meeting diverse application requirements.

De-labeling machine final product display

Compared to the traditional method of directly crushing the entire bottle (including labels and caps), removing labels first can effectively prevent impurities from mixing into the fragments, thereby improving the purity and quality of the recycled flakes.

As shown in the figure below, plastic bottles that have had their labels removed appear clean and neat, making them more suitable for subsequent crushing and cleaning processes, which greatly improves recycling efficiency and product quality.

main structure of PET bottle label remover

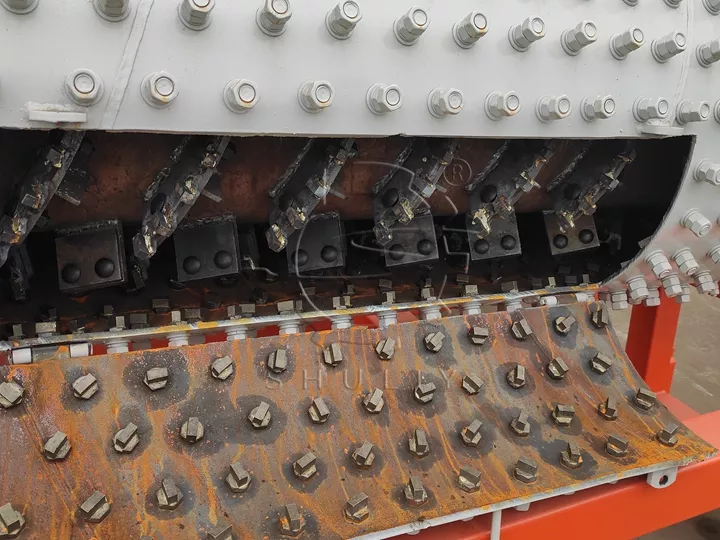

- De-labeling unit: the core structure, which includes blades, hot water, steam, or chemical treatment unit for removing labels and adherents from PET bottles. For optimal performance, the knives inside this machine can be easily removed, sharpened, and replaced.

- Control system: used to monitor and regulate the operation of the de-labeling machine, including controlling parameters such as conveyor speed, temperature, or pressure of the de-labeling unit.

Plastic bottle label remover working principle

It is especially important to be careful not to let iron or stones fall into the machine during operation. If they do, please stop the machine immediately. The following is the working process of plastic bottle label removing machine.

- The item to be processed enters the de-labeling machine via a conveyor system. The system positions them to ensure that they enter the de-labeling area accurately.

- Inside the plastic bottle remover are sharp, tough, alloy-jagged knives that cut and peel the labels away from the plastic bottles.

- These special, claw-like knives are welded by copper onto a fast-rotating spindle at specific angles to push the bottles forward. As the labels are cut away, they are blown into a collection chute.

In the PET bottle recycling line, the bottles treated by the label removing machine enter the plastic crusher and washer to continue the operation. To learn more about these machines, click: Waste PP PE Plastic Crusher Recycling Machine, Friction Washing Machine For Plastic Clean Recycling Plant, PET Bottle Flakes Hot Washing Tank Recycling Line.

benefits of label separating and removing machine

- Heavy-duty structural design supports continuous operation for extended periods. The blades are removable for grinding, facilitating maintenance and replacement, thereby extending service life.

- Label removal efficiency exceeds 98%, with a bottle damage rate below 5%, maximizing the retention of the original bottle shape.

- Reduces manual intervention, enhancing the automation level and production efficiency of the entire recycling line.

- Compatible with PET bottles of various shapes and sizes, offering excellent versatility and flexibility.

- Effectively prevents labels and residual adhesive from causing blockages or damage to subsequent equipment such as shredders.

- Compact structure with a small footprint, making it easy to install and use in various factory environments.

- Adjustable speed and pressure settings can be tailored to different label materials and bottle conditions to ensure optimal label removal performance.

machine technical Specification

Our PET bottle label removing machines have been shipped to more than 20 countries including Oman, Ghana, Kenya, Tanzania, Nigeria, Mozambique, Cote d’Ivoire, Ethiopia, etc. The following is the Shuliy hot-selling model, want to know more about the information, or to get the price of the label removing machine, welcome to contact us at any time to consult, and we will give you a reply within 24 hours.

- Model: SL-600

- Main power of machine: 11kw

- Power of fans: 3kw

- Capacity: 1-1.2t/h

- Rate of removing the label: 98%

- Size: 4000*1800*1600mm

- Weight: 1500kg

our service

- Our service covers the whole process of sales: before, during, and after sales. The hotline is open 24 hours and responds quickly.

- You can send us samples and our engineers will recommend and customize the machine according to your product and other needs.

- We provide preventive maintenance and after-sales service and test the machines before delivery.

- We provide 1 year warranty. You can tell us if there is any problem when using it. Our engineers can go to your factory to help you solve the problem.

You can contact me online or send an inquiry. Please provide your request details as clearly as possible. This way we can send you the price as soon as possible.